|

|

|

|

|

|

Other homemade CNC tables

|

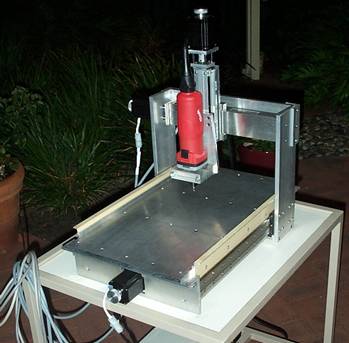

Rod's cnc routers. "Here are

a couple of photos of builds I have done of gantry routers. Each Link

to build here:

Nobott

was the next and was very similar to Obott but a few mods to make

|

|

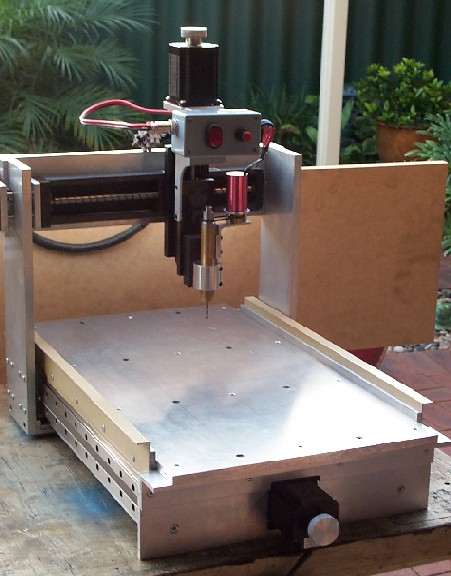

Third machine

was Jabott and this was just a fun little project using up bits

and pieces I had accumulated.

Fourth Machine was Rodot and I took a lot of time modifying my design to improve the machine. Note the cranked gantry. http://www.cnczone.com/forums/showthread.php?t=41154

Here is a hybrid X2 mill I did. It has a larger table and very much modified column. Probably not the sort of thing you want on your site as it is more for metalwork site.

And finally the project I have just finished which is a standard X3 mill converted to CNC and then an enclosure built around it.

I

have heaps of photos of finished products I have done which might

help people see what things are possible on a CNC machine. It is

funny but the first question everyone asks me after they build a

machine is what can I make with it. I have also experiented with

vacuum systems, touch plates, vacuum tables so plenty of material

to add to your site. Some samples of Rods work.

|

|

|