|

|

Forum Index : Windmills : Problems with Fisher Paykel motor

| Author | Message | ||||

| Seb1 Newbie Joined: 01/04/2019 Location: United KingdomPosts: 3 |

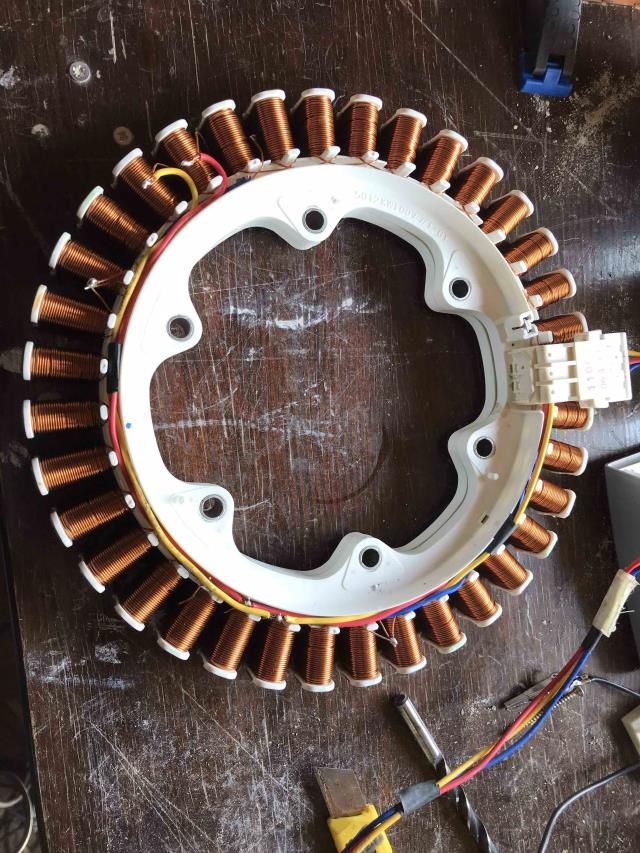

Firstly apologies for my limited electrical knowledge but I am hoping someone on here might be able to tell me where I am going wrong. I have taken a Fisher Paykel motor out of a washing machine. It is a 36 pole version. I have rewired it to 3 x 4C as per the great diagrams on this site. I have cut back the parts of the washing machine housing and am still using the original hub from the washing machine. I have wired it up to a 3 phase rectifier and then is wired to a light bulb. Hand turning produces nothing. I attached it to an ammeter which produced a large amount of resistance in terms of finding it hard to hand turn it. I have attached a couple of photos to show you how far I've got. Any advice is greatly appreciated. Seb the novice.    |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5012 |

Finding it hard to turn with the amp meter connected is normal, a good sign. Was it also difficult to turn with the light bulb? It should be, but not as hard as the amp meter. Can you test the output volts while turning by hand? Also thats not a F&P, its a LG. Works the same. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| BenandAmber Guru Joined: 16/02/2019 Location: United StatesPosts: 961 |

You will probably need a multimeter it won't cause much resistance and you'll be able to see how much voltage it is putting out at what RPM when these motors are shorted out they are very very hard to turn be warned i am good parrot but Dumber than a box of rocks |

||||

| Seb1 Newbie Joined: 01/04/2019 Location: United KingdomPosts: 3 |

Thank you to both of you for your replies. I hooked it all up to a multimeter and handturning it, it produced upto 20V. I tried it with an old bike light made up of 5 LEDs which lit up, flickered and then went out (I'm guessing I fried them). So, I'm really pleased that it works but now want to work out how to regulate the voltage output. This is a project for the children in my school so I want to show them something that is stable and can produce approx. 12V. Any suggestions on how to regulate/control the voltage output would be greatly appreciated. Seb |

||||

| sonny97301 Newbie Joined: 10/08/2019 Location: United StatesPosts: 8 |

some late info. if you want a good pma, just BUY ONE. on ebay/amazon. look for permanent magnet alternator, and KNOW what specs you want. re-purposing an f&p motor is LESS simple, than one might think. the motors are MULTI-pole, 3-phase, bldc, outrunners. in a 36 pole stator, there are TWELVE coils per phase. in a pma, there should ONLY be three coils per phase. changing the config of a stator, DOES NOT CHANGE THE CONFIG of the stock rotor. some people have come to believe that it is a good idea to Interconnect ADJACENT coils. IT IS NOT. |

||||

| itchybum Newbie Joined: 03/02/2020 Location: AustraliaPosts: 6 |

Hi all. I am in the process of designing a generator from a Comet windmill. Yes, there are quite a few challenges. Can anyone advise me of the best speed range for a Fisher & Paykel motor when modified and used to generate power? Speed increasing gear will be required, but to what approx ratio? Many thanks from SE Queensland. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

How about a treadmill motor ? These are typically rated at something like 4,200 rpm at 180v and maybe 8-10 amps. At 12v it should run at around 280 rpm as a motor, speed being proportional to voltage. That is about 4.7 turns per second. As a generator it might need to turn a bit faster than that, but not by very much, and should light a pretty big 12v light bulb to a couple of amps fairly easily. You probably don't need absolutely full glaring white brightness for a nice class room demonstration, so hand cranking should produce something quite worthwhile. A bicycle hub generator might be another way to do it, if you can find one. Cheers, Tony. |

||||