|

|

Forum Index : Windmills : Diodes on star centre connection

| Page 1 of 3 |

|||||

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5012 |

Been a bit of interest on adding diodes to the center point of a multi phase star alternator. About 10 years ago I was talking with a auto electrician mate who said he was starting to see car alternators with the diodes on the star. He said on the test bench they were definitely making more power. I've been trying to find some more info on google, but its knowing the right question to ask thats the hard bit. On one thread I did read a 10% gain, at a fixed rpm into a battery load. Of course this also means more power is needed to drive the alternator at the testing rpm. I suspect the power output for a fixed rpm would be somewhere between star and delta. The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

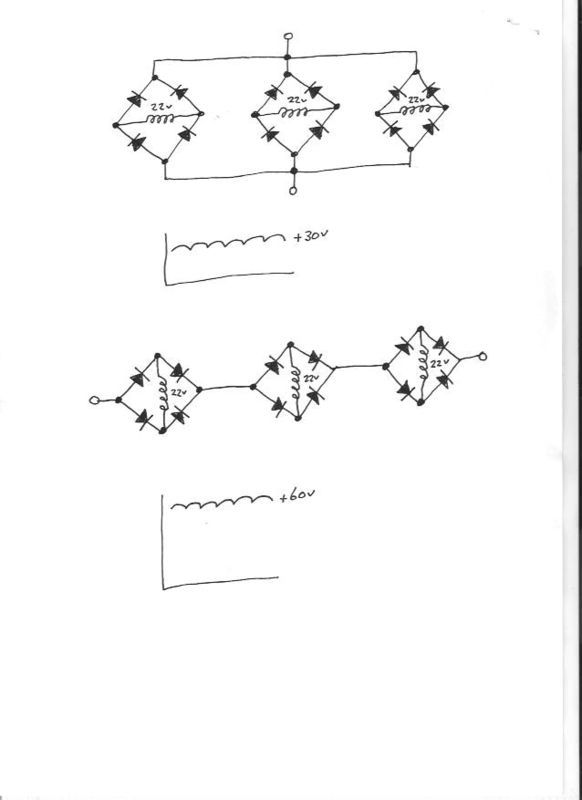

Just to mention something I did a while back that may or may not be useful or relevant to all of this. I have a large three phase transformer that originally came out of a 24v industrial battery charger, must be about 5Kw, not really sure. But it does have three independent secondary windings, rather like an F&P. As we know, star or delta connection gives a choice of two different dc output voltages, but there is a third way. What I did was connect each winding to its own conventional four diode bridge rectifier. The three bridge rectifier dc outputs could then be connected either in parallel or in series. The parallel connection behaved just like a normal six diode delta connection giving a nice smooth low ripple 30 volts dc output as expected. Connecting the three bridge rectifiers in series exactly doubled the output voltage to 60v, also giving a nice smooth low ripple output which is higher than you can get with star connection. I have no idea if this has any practical application for wind turbines, but just thought I would throw this into the discussion. Cheers, Tony. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

This is a copy of a response I did on another thread, but more inline with this thread. It was in response to Dave's test, that did not yield any response from extra diodes in his test rig.... and why this may be so. "Dave, The extra diodes won't work on a properly loaded machine.... only when it is poorly matched. Then the star voltage will sag, while the dleta catches up to it, and then it can augment it.... before that ( or if matched, and the emf allowed to rise proportionally) then the star will always be above the delta, byt about 1.6:1, so the delta emf will be lost in the background, and cannot contribute until the star has sagged at least below the delta figure. Because you know what your doing, you are likely to be matching the load fairly well, and so the delta "switch " will not happen, you will have to loose at least half the EMF in the coils in star before the delta should kick in. We should transfer this part over to Gizmo's other thread, in fact I will copy this answer over to there, and that may help others understand what i/we are trying to explore. ........oztules" Warp..... that would require cap filtering to work? Once you use transformers to match impedances, you can dial up whatever you want really I guess. .........oztules Village idiot...or... just another hack out of his depth |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

For those interested in experimenting, this is my take on whats happening, and why I would try to do it if I had a F&P mill. If we wire in star, we get an early start up, which is a good thing... except that our output will suffer terrible reactance problems fairly early on at say 10 amps...(or less?) and then thats it really... the end of the power increasing as the wind does. In star we are using two phase coils in series, so we have twice the turns for the resistance value than would a delta or single phase coil configuration. Our voltage is about 1.6 times as high as would be delta, but or resistance is double.... but just as importantly the number of turns has doubled for the same current.. so our amp turns is a lot higher. These amp turns generate an opposing magnetic field that will react against the ferrite magnets doing the magnetising in the first place, and a stand off occurs when the repelling field from the amp turns in the stator interfere enough with the magnetic field from the ferrites, as to cause a top limit to current.... no matter the rpm after that, we reach stalemate. If we add two more diodes to the star point, we create another path for the electrons to get out of the stator... this time, the amp turns is for the single phase coil not the two in star.... likewise the resistance, so at this point it should start acting as a delta stator. It should return the same results as a delta configuration now... as that is what it really is. As the rpms drop off, the delta will lower it's emf output to the point where the star starts to take over..... thats a simplified version, but I think gets the idea across. The reactance should be such that it is pretty messy at cross over, and I would expect it to be relatively smooth. It can only work with iron cored alternators who's synchronous impedance is such that they can run safely in reactance current limit state..... A air core axial flux would just burn up if it tried too emulate this. So properly matched units will not be able to do this, as the star will not sag below the delta point ( about 60% of star ).... nor would it need it, as the emf would rise with rpm.... so there would be no current limiting by this mechanism.... eg mppt grid tie unit. A traditional hook up would benefit from this I suspect, where you could start lower rpm, but still squeeze a few more amps in when the wind picks up... maybe another 20% or more. Bench testing a car alt would require a big battery bank that would keep the lid on 70 amps or more, without rising too fast. That may be why the 10% figure was mentioned Gizmo.... but there is no reason I can see for it to be that low only... it really is a delta connection, and a car alt should be fairly feral in delta I would think.... maybe test out the belts if the batts were low for a few seconds. .......oztules Village idiot...or... just another hack out of his depth |

||||

| Boppa Guru Joined: 08/11/2016 Location: AustraliaPosts: 814 |

I dont know about the fp stators, but it was quite common back in the eighties to change star wound car alternators to delta for the extra amps they provided- they didnt start charging until about 2500 rpm, but once they did a bosche 55a would easily pump out 90a, some broke 100a very popular with anyone who wanted to run more than 4 130w spotties before the modern 80/100a alternators became available (ps hate typing on tablets/phones- gimme a real keyboard anyday) |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

The waveform coming out of the three bridge rectifiers series connection is almost pure dc with only a very few percent of ripple. No capacitors required anywhere. It appears that all three phases when added together in series (through individual rectifier bridges) add up to twice the peak voltage of one phase. And due to the magic of sine waves this addition produces an almost constant dc output. I was curious about this as I have never seen it described in any engineering texts. But it definitely works giving exactly twice the dc output voltage that you would expect from a delta connection plus single six diode bridge. If I had a camera I could show you the beast, the measured voltages and the waveforms. I bet it could beat a capacitor multiplier, especially at very low frequency. How it could be incorporated into a wind turbine I have no idea. But I leave it for others to try out and experiment with. Its easy enough to try. Cheers, Tony. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I actually bought one of those upgraded alternators, remember it well. Never really knew what they did to them, which makes your comment very interesting. Cheers, Tony. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Not quite on topic, but Warp, your comments are very interesting. Using a ac waveform to charge batteries is very wasteful in single phase, in that the power factor from crest damping is very severe, and a petrol genny struggles to do well... ie the power factor is miserable due to the crests used only. If your setup is delivering almost ripple free DC..... gee I suspect we could get better kwh into the batteries than normal rectification. In theory, we use no extra power in petrol with poor power factor, but in practice we still need to generate much higher current in the alternator coils to deliver a vector product into the battery. I notice this loads the genny down significantly more than the power it is actually seems to deliver..... current equates to torque I think. I have rewired and built 48v alternators from normal car alternators for battery bank charging, and even though they are three phase, they still load the motor up more than I would anticipate.... maybe if I used your three rectifier system, I could reduce the motor load for the same power output.....( less wild harmonics??) I guess I will have to try this... ie bypass the normal diode block, and use three single phase blocks in series.... always something else to try. ( and change the pulley ratio too ) ..... thoughts before I do this? Boppa, that sounds encouraging too. .......oztules Village idiot...or... just another hack out of his depth |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I have been sitting here thinking about this myself. A standard three phase rectifier, either star or delta can put out an almost pure dc voltage with only a very slight voltage ripple, and the load current will be continuous. This continuous load current commutates abruptly between whatever diodes are conducting. The current through the windings must always be a square wave that chops on and off. With the series connection, this is also true, but the current through all windings must be continuous, but rapidly reversing in each winding during each zero crossing. Really fascinating stuff. Cheers, Tony. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

This is the general idea:  Cheers, Tony. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

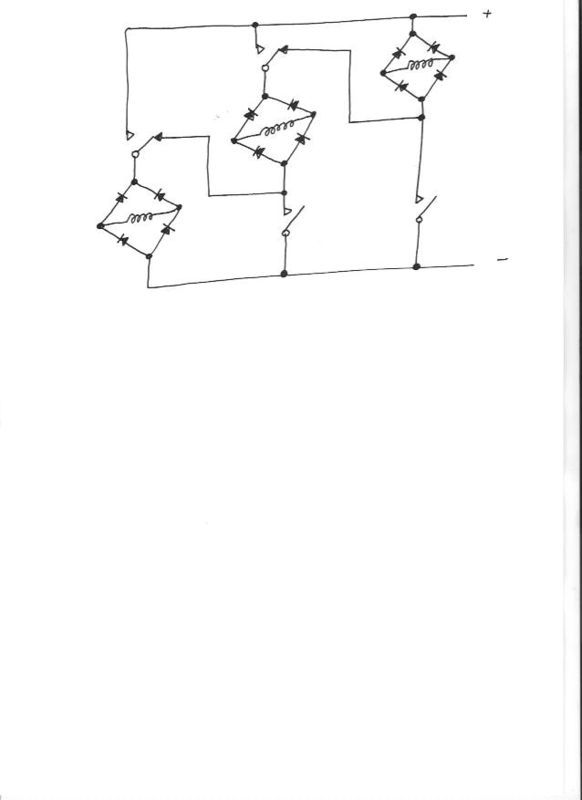

The voltage doubler could be switched in and out with a (horrible) four pole relay, at least to try the idea initially. I would expect the parallel system to work the best once it has reached cut in speed, and gets going as it will produce a higher current. But the voltage doubler might provide some useful output below that point. If crossover could be arranged where both systems are providing similar output power, switching over could be pretty seamless. Not terribly thrilled with the idea of using a relay to do this ! But if the concept works, something a bit more sophisticated could be used to do the switching electronically. Need to think on that a bit more. But the quick and dirty way is with a relay.  Cheers, Tony. |

||||

| Boppa Guru Joined: 08/11/2016 Location: AustraliaPosts: 814 |

they were actually a really easy job on the bosche one, not so much so on the lucas ones inside you had 3 wires twisted together, soldered and sleeved in a ceramic sleeve- you just unsoldered the three together and the 3 off the diodes plate, joined together in a delta (you had to make doubly sure to get the starts marked with a blog of liquid paper), joined start to finish of next winding and resolder the joined wires to the diodes (usually had to extend the old y join ones in the bosche) and bingo, done some people told you you shouldnt do it because you would `run out of voltage', but most of the ones I did were fine, the usual 55a bosche would get up to 19vac or so in y connection, even in delta they would still get up around 16vac which was enough to get your 13.8dc at the battery |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

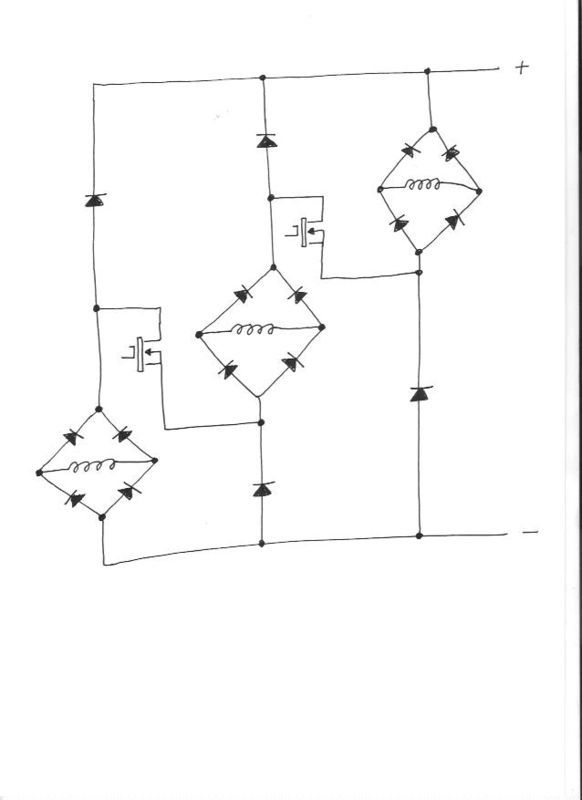

That uprated alternator worked fine. I had no idea it was such a simple conversion, I thought it must have been rewound. Anyhow, more thoughts on how to electronically switch this voltage doubler in and out. This idea is completely untested, but should work as far as I can see. The mosfets will need to have isolated gate drive, but when they both turn on together it will force the the three diode bridges into a series connection. Once the wind turbine is up well above cut in speed and producing serious power, all the current is carried only by diodes, both mosfets being off. I expect that voltage doubler mode would only be used below usual cut in speed, so the mosfets should only be seeing minimal current, so they and their heatsinks need not be huge.  Cheers, Tony. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Just had an even more interesting idea. Our F&P has multiple coils per phase, so we are not limited to only switching three phases series/parallel for just voltage doubling. If individual coils, or groups of coils have their own independent bridge rectifiers, we can stack more than three bridge rectifiers in series, and switch them in and out in groups using the above mosfet switching system (assuming that it works as expected). It may be possible to get much higher voltage multiplication than just doubling, and more voltage steps. The advantage is that at low wind speeds we only have low power, so the current in the series connected windings will not be high, but we can get a much higher voltage at very low rpm. As rpm and power increase, we are running more of the the windings in parallel which not only reduces the output voltage, it multiplies the output current without overloading individual coils. If this can be done, and properly controlled, it could be an excellent solution to matching the alternator to the turbine over a much wider operating range. I do not have a turbine or F&P here to play with, but if someone else here can pick up the ball and run with it, that would be great ! Cheers, Tony. |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

The sum of all 3 phases at the star point with respect to all 3 phases going to the rectifier is always at half of what is feeding into the rectifier. This occurs even during excessive load so going into saturation makes no difference. The star point is at the middle of all three phases electrically. I've measured the AC current between the star point and the extra 2 diodes and it comes to ZERO even under max loading conditions. Maximum current that I got out of the test 80s standard star stator was 2.84 Amps at 600 RPM. That is 40 % greater than the optimum of 2.04 Amps when load matched correctly. Tried fitting caps in different configurations to move the phase angle but everything shifts as it's a closed loop circuit. Tony on the 'Star/Delta Controller' topic I proposed something along similar lines to what you have added to this discussion re a switching system. The above is now way out of date and thinking of a different concept yet again using the same principle above but fitting cap doubles to up the output power. Second aspect is to use a dual stator set up to start on one at cut in and do the switching over at offset RPM level's. This allows one stator to always be online while the other is switched into a more efficient mode. Switching occurring at a point close to that stator running into full saturation. This gives an added advantage of no big voltage/current changes at the time of switching. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

There won't be any large voltage changes at the point of switching in a real system, because a large battery virtually fixes the output voltage. The problem of what happens at the exact point of changeover (no momentary shorts, no briefly running open circuit) is solved by using a combination of diodes and mosfets as suggested. But I agree switching should be fast and clean to avoid high power dissipation operation of the mosfets. If the switching points are well chosen there should not be any large jumps in current. Think of it this way, if the system is running below cut in with all the windings connected in parallel there would be no current. As we reach cut in speed the parallel windings would reach sufficient voltage to begin working. We do our switching when the current in parallel is equal to what it is already producing in series. From that point onward the current rises with rpm. So when we change over there may not be such a large jump in output power if the changeover point is well chosen. If that can be done, while also matching the power curve of the turbine I really do not know. Getting more grunt out of the alternator at very low rpm is only half the problem. We need to do that without stalling the blades. Running with a real wind turbine and charging a battery is very different to bench testing into a resistive load. Cheers, Tony. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Disappointing Dave, the theory is good , but the results are strange..... not sure why ........oztules Village idiot...or... just another hack out of his depth |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Yes disappointing is the word, as it showed such potential... Tried fitting an extra full wave rectifier between one of the output phases and the star point. When the 3 phase star output rectifier was at 100 VDC under maximum loading the output of the extra rectifier was at 70 VDC. This tells me that those 2 extra diodes in the other configuration are not able to go into forward conduction. I would need to know more about the electrical characteristics of the other alternators that this technique has been applied to successfully. There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

It was designed with the quick change to delta for easy fitment to match the revs of diesel engines probably made back to 1970 or maybe even earlier. I think with a twin v belt pulley that was slightly larger diameter as well. The bosch was OK but the early lucas was a pain, the voltage regulator and other bits were constantly failing from vibration and dust. I'm confused, no wait... maybe I'm not... |

||||

| DaveP68 Senior Member Joined: 25/11/2014 Location: New ZealandPosts: 292 |

Hi Tony Have tried wiring up an 80's stator in the configuration you suggested. Removed the star point and wired each set of 14 poles per phase to it's own rectifier as per your drawing below. Got the exact results as you described. One advantage to taking this approach is the voltage levels are better than the standard star output. Standard Star on an 80s is 0.685 VDC per 1 RPM vs Delta at 0.395 VDC per 1 RPM. With your set up we get a slightly higher volts per RPM in the series mode of 0.787 VDC per 1 RPM. The parallel set up is the same as Delta at about 0.394 VDC per 1 RPM. I can see merit in the way this works as the cut in RPM can be reduced by about 18 % if required (18 % higher for same RPM). Good work and keep those new ideas coming through. Next step is to try out your switching idea with the view to publishing the results. This could take me a week or 2, as got a bit of other stuff on my plate at present. Cheers David There are realities if you do not accept, will lead to frustration because you will be spending time on wrong assumptions and the results cannot follow! The Dunning Kruger Effect :) |

||||

| Page 1 of 3 |

|||||