|

|

|

|

Print Print |

|

|

| Windmill Kit, no longer supplied.. |

|

Turbine

Blades

You have several options for windmill

blades. I wont go into the details of their design or

construction as there is already an abundance of information

on the internet about making blades.

The best blades the home builder could

make are carved timber blades. With timber you can achieve

a near perfect set of blades, but the process is very

labour intensive and require some timber working skills,

of which I have very little. My first set of timber

blades were cut from 18mm ply wood, and shaped into

a basic airfoil. They did workgood, but I was then lucky

enough to receive a set of carved timber blade my by Dennis Latham of South Australia. These were beautifully finished

and have performed better than my own blades. To find

out how to make your own timber blades visit Hugh's web site.

There has been some development in

using large diameter PVC pipe as blade material. By

cutting a PVC pipe lengthways and reshaping the leading

and trailing edge with a file, you can achieve a near

perfect blade profile, and the process is so simple

you could make a complete set of blades is a few hours.

You would need some large diameter thick wall pipe,

250mm diameter and 10mm wall thickness. A concern it

that PVC is a bit of an unknown for durability. UV light

will weaken the PVC and it may shatter, sending sharp

PVC splinters in all directions, so a safe operating

life of 2 years or less is expected. Dennis ( above

) is also experimenting with PVC blades and is getting

good results, I will update this page as his work progresses.

Another option is the use of factory

made plastic blades. You can get a set of blades from

Michael of EcoInn in New Zealand. He sells a set of 6 blades to make a

1.5 meter diameter propeller for $220 nz. I have a set

of these on order and will give them a try.

|

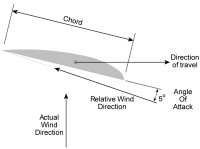

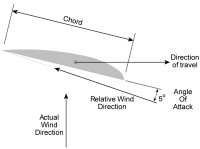

| Blade angles

and cord need to be calculated to suit your windmill. |

|

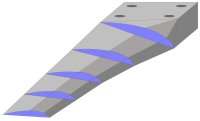

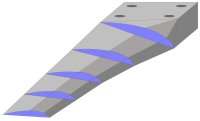

| The blade profile is calculated

at stations along its length. The diagramme here also

shows the blade twist |

|

| You can download a blade

calculator here.

Its an excell spreadsheet so you will need to have Excell

installed ( part of MS Office ). The formulae used is

based on the work of others, so I cant guarantee its accuracy. |

|

| These are the blades made

by Dennis before I mounted them on my windmill. They are

performing very well. |

|

| A set of plastic blades

from EcoInn in NZ. Once assembled the propeller diameter

is 1500mm |

|

If you just want to make a set of simple blades

to get your windmill going, click on the image below. It shows

how to make a set of blades from 18mm ply wood that might

not be as good as properly carved blades, but will work well

neverless.

Next

- Propeller Hub Assembly |

|

|

|

|

|