| Menu | JAQForum Ver 19.10.27 |

| Menu | JAQForum Ver 19.10.27 |

Forum Index : Other Stuff : Making PLANTE batteries. 550ah 2v cell.

| Page 1 of 3 |

||||||

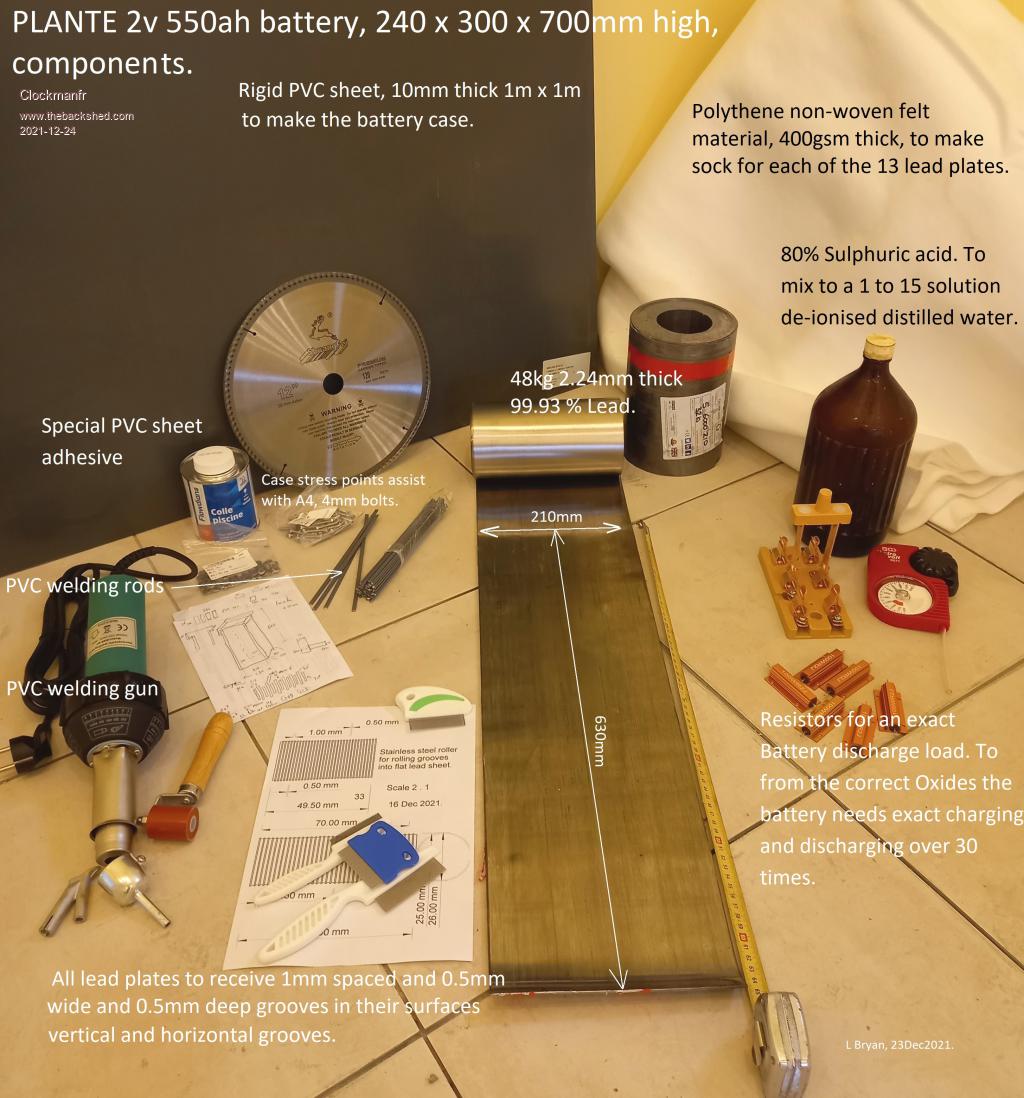

This is for Davo99 and freinds here. I will post at significant milestones. Everything is now here, so away i go with the physical construction. The case can not be defined to exact dimensions until i have made the socks and stacked the plates together. This will then determine the inside dimensions with the socks on. The 400gsm polythene non woven felt Geotextile is really porous for the acid solution. Polyethene is the same as polypropylene at handling 80% pure sulphuric acid.  Everything is possible, just give me time. 3 HughP's 3.7m Wind T's (14 years). 5kW PV on 3 Trackers, (10 yrs). 21kW PV AC coupled SH GTI's. OzInverter created Grid. 1300ah 48v. |

||||||

Really looking forward to this ! |

||||||

me too warp... |

||||||

Yes, will be interesting to see this develop. The scored scratched surface has proven successful so far and proven to work.  Edited 2021-12-24 12:28 by Revlac |

||||||

Or speed things up by making some textured rollers for an old time laundry mangle? If there are a lot of cells to do it might be worth the effort. |

||||||

Interesting project, looking forward to your updates. I have not seen a knife switch for many years, the one pictured looks new, is this an 'only in France' available item? That battery is going to be heavy, I hope your back is up to it. I'm also curious how you connect the plates to the terminals, considering there will be a considerable weight hanging from them. |

||||||

Quite a few Chinese knife switches (Frankenstein switches) on flea bay. |

||||||

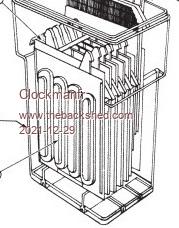

As 'Warpspeed' says, lots in China new. I need a knife switch as the voltage is low but the amperage is high, and especially as i have so many charge and discharge cycles required before the battery is ready for use. The battery weight was my main size criteria ie, what can i lift on my own, so i stuck to something around 50 to 60kg. What i am trying to do is keep equipment that is required nominal, ie what you yourself will have to get hold of. But i will supply if needed, a stainless steel hand roller that is pre machined with the correct groves at the correct sizes, polished and about 26mm diameter and 55mm long. This roller will therefore give consistence results to all plates equally. The plates are 2.54mm thick so you do not want those grooves to deep. Regards case. The top will be removable ie bolted on, although still struggling to get small quantities of sealant with VITON in it for Europe. The top has hangers and the plates are also supported at the base on alternating positive or negative supports. Top of the case will look like this photo.  Edited 2021-12-24 19:42 by Clockmanfr |

||||||

Local telephone exchange 50 years ago had a battery room about 200 sqm full of large open vats with hanging solid lead pouch plates, must have been several thousand liters of acid, huge fan at one end for ventilation when working in there, remember it was a horrendous job taking specific gravity measurements each week. Cheers Mike |

||||||

"it was a horrendous job taking specific gravity measurements each week." Yes, many years ago had to do that for several 415V three phase UPSs with large batteries (460V on charge). The 25kW ones had 198 cells and the 50kW one had two 200 cell batteries. They had been in storage too long and the plates were encrusted with hard sulphate. During commissioning all the cell volts and SGs had to be recorded twice a day for a couple of weeks while they were cycled up and down revive them. The large one was supposed to run for 12 hours at full power. Big cells. |

||||||

If I were doing this myself, I think I would buy a small bead roller machine either from flea bay, or secondhand from a tool/machinery/junk dealer. Something like this perhaps:  |

||||||

Thank you for your reply. So the plates 'hang' on the cross bars of the post pillars and make contact to them due their weight? Or is there another, perhaps more secure, electrical connection between hanger and cross bar? |

||||||

Warpspeed, We need to create a matrix grid pattern in the lead sheet, so the surface area and the oxide formation is stable and at least 0.5mm into the surface of the lead sheets. Using rollers is great but going horizontal with rollers may be an issue. However if you were to manufacture the rollers with the correct 0.5mm depth and 0.5mm wide then maybe. But i am trying to keep all the making stuff as simple as possible, hence a hand roller that can be manually pushed into the lead for vertical and horizontal grooves. Also intend to leave about 10mm of the original plate on its edges, un-grooved so to aid stiffness and structure to the lead plates. But this will need assessing further. Murphy's Friend, I am trying to keep the contacts from the plates themselves to the case as minimal as possible hence the hanging concept. But this will also need assessing and i might form small plates from the plate support bars that could take a lead rivet through them. But again needs accessing for simplicity and simple as possible build process. Also have to work out if the battery itself were to fall over what would happen? Yes, i have plans, and tested some stuff, but its trying to keep it simple, Robust and yet cost effective. Remember, I am inventing as I go, and that what good R&D is all about. Edited 2021-12-25 20:25 by Clockmanfr |

||||||

It might take a lot more applied pressure than you expect to physically displace lead over the width of a practical width of roller. A decent bead roller can apply literally tons of compressive force, and a large diameter crank handle turns a relatively small diameter pair of rollers to slowly draw the metal between both rollers. Its not obvious from some of the picture, but the upper and lower rollers are coupled by spur gears to prevent the rollers slipping on the material. Its usual practice to pair a convex roller with a matching concave roller, but almost any shape roller could be turned up fairly easily on a lathe to suit the requirement. Bead rollers always have a fairly deep throat so beading can be done over the surface of a fairly large sheet some considerable distance from the edge, so beading directly across a sheet should be possible if the throat depth of the machine is sufficient to suit the length of your plates. A smaller sized bead roller may still be capable of putting diagonal grooves in fairly long plates. https://www.youtube.com/watch?v=Z9hxXUYK36I Those shiny new Eastwood machines look expensive, but something suitably old and second hand might turn up with a bit of foraging.  Edited 2021-12-26 08:36 by Warpspeed |

||||||

Jaycar carries them. Not called a knife switch in the catalogue from memory, battery isolator or something similar. |

||||||

I've seen this battery mentioned a few times, but I'm not sure what the basic premise is. Is it cheaper, has a longer life than a commercial AGM, maybe both? |

||||||

Advantages. Advantages. Firstly, it's a simple cell lead acid battery. Secondly, If made correctly it lasts a life time, ie, your life time, say 40 to 50 years. The more you use it, the more Ah capacity it gets. It can be made from readily available materials at a reasonable cost. If we make the case correctly, our PLANTE battery can be easily dismantled and the lead plates cleaned and repaired and the battery put back into use. It has the same rolled lead plates for both Anode and Cathode plates, so just lead sheet and no extra added nasty chemicals. However putting a modern twist into this story, we intend to use a 0.5mm grooves at 0.5mm depth at 1mm spacing vertical and horizontal on each lead plate. This will vastly improve the active surface areas and help hold and form the Oxides we form during the charge and discharge function when commissioning each battery. Its electrolytic medium is still 15 parts volume de-ionised water to 1 of Sulphuric acid, I used to use a 80% pure Sulphuric acid as my acid mix. REMEMBER NEVER, NEVER pour water into Sulphuric acid, YOU MUST ONLY POUR ACID INTO THE WATER, and do that SLOWLY as the acid still makes things get hot quick and spits and spatters. Today ready mixed battery acid is readily available, but at present I have not tested any commercially available product, as I am never sure any more of commercial QC, Quality Control. It will have POLYPROPOLENE or PVC battery container/case is now easily obtained and, in all shapes, and sizes and can be easily manufactured for your own purposes. Polypropylene or PVC is the container for our PLANTE battery and is not that much affected by the Sulphuric Acid mix. In the old days it was Glass. It has POLYPROPOLENE or Polythene non-woven cloth, which comes in a good assortment of mesh sizes or GSM. This material will be used as a insulator between the Anode and Cathode plates, and will be sewn or seam welded to form a sock on each plate. No more making plate separator combs, yippee! The last important reason for our PLANTE battery is that we can really stack the plates tightly in the case, so acid use will be minimalised. Disadvantages of our PLANTE battery. Firstly, Because we are not using all those extra chemicals and a plate grid matrix construction method, Our PLANTE battery for equal physical size of a commercial standard lead acid, ours will only have about 1/3 rd of the Ah capacity. This is an important consideration as we need to do a fair bit of costs examination of our manufacturing to see if our PLANTE battery project is truly COST EFFECTIVE. Obviously some of the Pros are fantastic, but the poor Ah is a drawback, so hence going for a big battery, about 60kgs, that you can just lift yourself. Secondly, The PLANTE battery process of forming the battery is a long winded, as the battery needs its plates forming with the correct oxides. This is normally seen as a minimum of 40 charge and discharges and must be done precisely to get the correct oxides forming on the correct plates. I have done all this and I have yet to get a battery when I start the process to form as I want, ie I connected everything up added the acid and the plates I designated as Positive turned out to be Negative when I tested them before even started the charging process, it seems that the Cell at first acid fill is actually bi-sexual. But once started its important to stick to the charge regime. After 40 charges and discharges the battery is put into service the more you use the battery the better the Ah gets. After reading the above you will see that I have had to design the PLANTE battery with several important design parameters, and sorting out the Cell plates internal resistance. Warpspeed...... Still working on the roller concept. Roofing lead comes ready annealed and is very soft. Pushing 0.5mm grooves at 0.5mm wide into it is not really an issue at present. Edited 2021-12-28 18:30 by Clockmanfr |

||||||

If you hang lead sheets, strips from a nail hole, over time - several years the lead deforms and the holes elongate. I have had a 1kg sheet of roofing lead about 2mm thick hanging from a nail in my garage for the past 15 years, what was a nail hole is now a thin slot; so you will require some sort of reinforcing in the area where the plates are supported. Possibly fold over the ends so they are double thickness or clamp together somehow. How were you going to hold the multiple plates of each 2V cell together and make the connections between cells Cheers Mike |

||||||

I agree with that, the connections could be the Achilles heel of this project. How about calculating how much a full size plate and sock will weigh in the specific gravity of the acid (it will be lighter than in air). You could then make a shorter but full width test plate with a steel weight added for experimenting the connecting method. This would not waste much of the precious lead sheet. Narrow, vertical on edge, PVC support strips across the plates at the bottom might also help getting some weight off the connections on top. |

||||||

This is the battery case design. Alternate plate support at the top on that lip of the case and the lead bus bars with angle small plates and lead rivets. At the base thinnish PVC support strips for lead plate support that also alternates.  |

||||||

| Page 1 of 3 |

||||||