Guru

Joined: 31/12/2016

Location: AustraliaPosts: 1152

| Posted: 10:51am 11 Nov 2021 |

Thought I would post this here, don't really want to join some 3D printing forum just for the occasional object built.

There are a few sheds around that have these as a side hobby, bit of electronics involved in some builds and many have built some some pretty unique gear.

This might be of interest to someone, its a bit expensive to buy parts and things, so most build there own and that's more interesting, certainly learning a few things along the way.

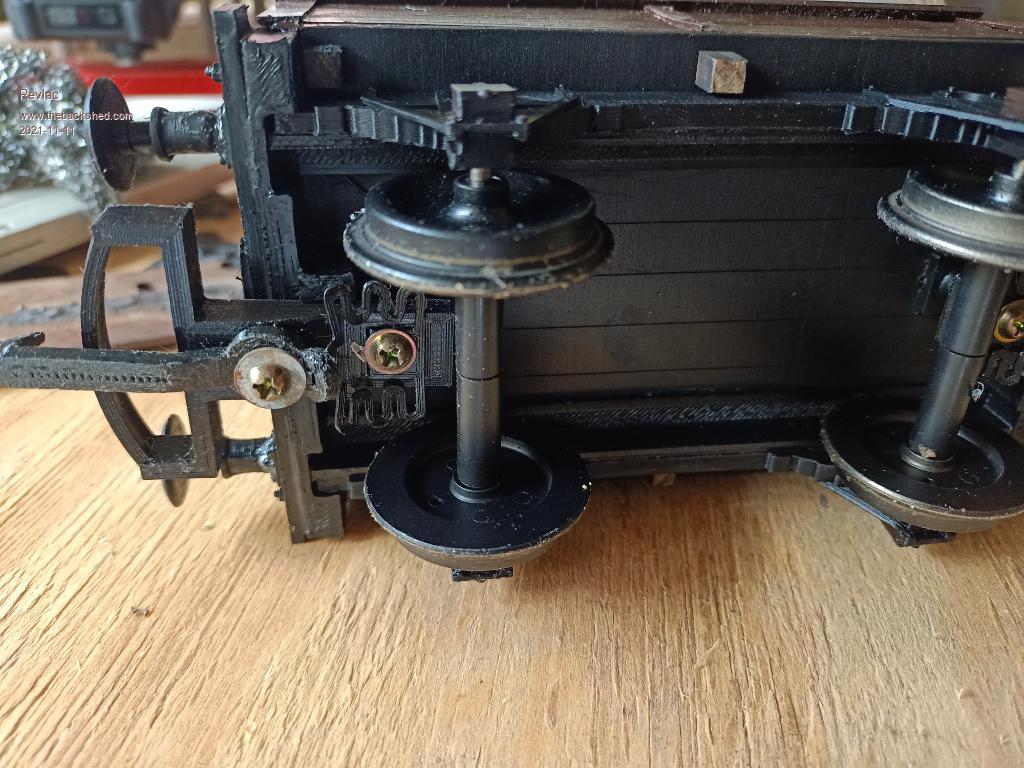

The wagon body was initially build to fit onto a friends (HLW) flat car, to house a sound card for the loco sound, and it works a treat.

Since then I was told that HLW no longer build the Flat car, so I made one the way I wanted and happy with it.

The wagon body, wooden parts are 1.6mm ply wood.

K40 laser cutter 11.5% power for cutting at 10mm per second, engraving at 10.5% 20mm per second.

QR hub caps, raster engrave, power depends on the grain and type of ply, 10% power 1 or 2 passes.

Currently there are 2 options low or high wooden sides/ends for the box, some sanding and fitting will be required, nothing is perfect

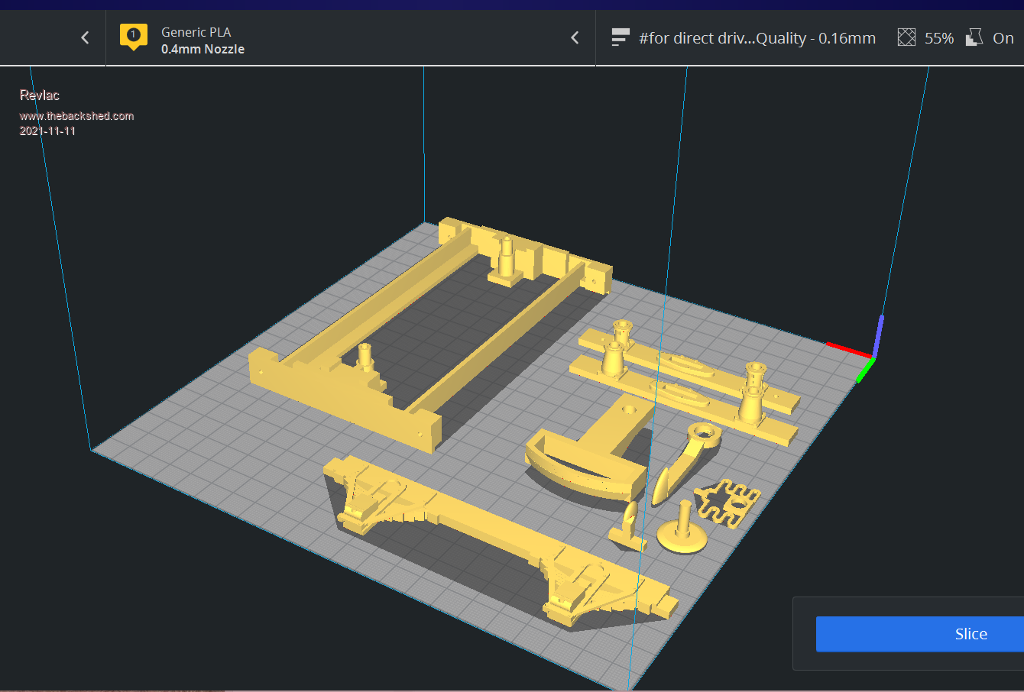

There are 8 different parts to be 3D printed, some parts you will need to print 2 off as you would expect.

2 wheel wagon G Scale 45mm track.zip

Zip contains,

4 svg files

9 openScad files

2 choices, wagon buffer beam or wagon buffer beam, cone shape.

And a folder with some screenshots of the STL loaded into

Wheels are generic, or make your own.

Feel free to modify.

And the STL files,

STL.zip

The frame can be printed with PLA, if you wish, the axle box sides where done with ABS and some of the smaller parts where done with ABS, some of it worked quite well, but other parts where brittle in places because I had trouble keeping the temperature differential low while printing with ABS.

Have since started using PETG for printing these and very happy with the results so far, print with what ever your happy with, the coupler spring remains springy with PETG, ABS is ok as well.

Now what have I forgotten.

Oh, on the corner's, used some small PVC angle, but it could me made out of something else.

Done another different style body, I might post some pictures later some time.

Cheers Aaron

Off The Grid