|

|

Forum Index : Solar : Running pool pump with treadmill motor - directly off solar panels

| Author | Message | ||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Thanks Brian. I found a flat ribbed rubber type from Bearing Service for around 50 dollars. The guy did not mention turning it inside out,but that sounds like the way to go . I,ll give your Toowoomba company a call . Still waiting if someone can help with that photo link I posted, buggered if I could convert it to a photo ?. Thanks Bruce Bushboy |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Cannot help with that link you provided Bruce, but here is another link you might like to try. I just went to "Google Image" and typed in "South Bend Lathe". https://www.google.com/search?hl=en&gl=ar&tbm=isch&source=hp&biw=1637&bih=920&ei=ZTwkYP_THITWz7sP5vqveA&q=South+Bend+lathe+&oq=South+Bend+lathe+&gs_lcp=CgNpbWcQDDICCAAyAggAMgIIADICCAAyAggAMgIIADICCAAyAggAMgIIADICCABQ6TBY6TBgsm1oAHAAeACAAZ0BiAGdAZIBAzAuMZgBAKABAqABAaoBC2d3cy13aXotaW1n&sclient=img&ved=0ahUKEwi_ms3UjuDuAhUE63MBHWb9Cw8Q4dUDCAY If you can identify the exact model South Bend you have from pictures, further searching using appropriate key words may turn up a lot more information. These lathes are incredibly popular in the US, and apparently parts are still available for them. https://forums.somethingawful.com/showthread.php?threadid=3767118 Funnily enough my own Le Blonde Regal lathe was built in 1945, five years before I was born, and I have owned it about half that time. I just discovered only this week that the American company that made it are still in business making lathes, and they can still provide genuine original spare part I might need even after 76 years. https://leblondusa.com/leblond-regal-lathe-parts/ Edited 2021-02-11 06:38 by Warpspeed Cheers, Tony. |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1584 |

It's not a link that can be followed. Looks like something that may have been emailed to you. do you know the original source / site where the picture came from? |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 904 |

Hi Bruce, that link looks like it's a file on your computer. If you want to show it in a post ... click on the 2nd-from-the-right icon at the top ... the one with a tree and an up-arrow ... ... then click 'Choose File' in the box that comes up ... ... then click 'Upload' and your picture should appear in your post. Good luck. Cheers, Roger |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

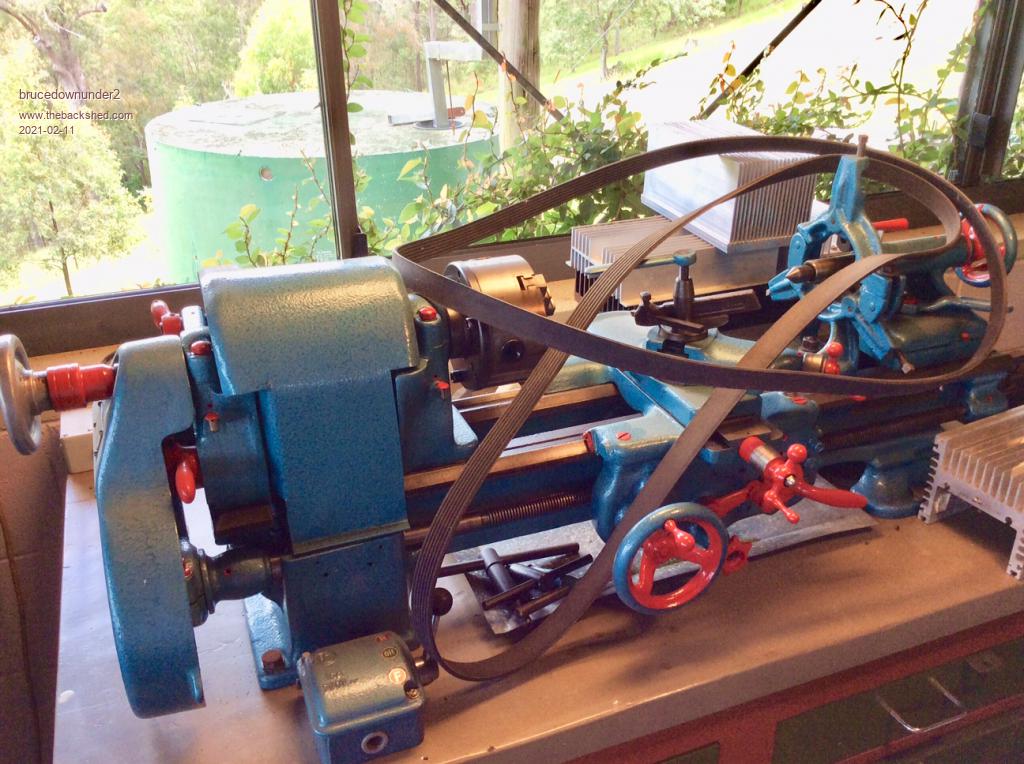

OK , managed to download my lathe Pic. Yes, the main drive spindle is removable, actually a must if you install a new belt. a couple of pillow blocks plus a grub screw and you can lift the drive train gear out . mine sits on a cabinet and the motor is hidden under the lathe, with the long drive belt running through a slot cut in the bench top under the headstock. I'll get one of those belts ,as I'm sort of finished my Solar installation now, and thinking of doing a new wind genie ,just for fun , and I have the tower with no genie on it. ( Anybody reading this thats got a wind genie finished or part finished thats wants to sell , let me know, 0427 747 748. ,might save me some stress.) I don't really know how to get that link to change to a picture , so if you can help ,tell me what to do ,please. I wish you all a nice day , I'm out to cut meter long grass for an hour or so -can't do much more than that nowadays. Bruce  Thanks Roger . and the other nice people that helped . Edited 2021-02-11 08:34 by brucedownunder2 Bushboy |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 904 |

The belt spray is certainly helping, though it only lasts a couple of days before becoming ineffective. Had a look yesterday at lunchtime and despite reasonable light was only running at 35psi. Just a whiff of spray and straight up to 70psi ... such a sweet sound.  The belt is so worn .. the peaks of the pulley ribs are almost cutting through the belt ... which is all of 7-8mm wide now that I've cut the damaged half off. When I bought the ribbed pulleys on ebay, I also bought some green polycord round belting, 3mm and 5mm. It can be cut and joined by melting the ends together. It's used for generally slower and gentler loads ... though in looking at videos of how to join it, I saw mention of it being used with small lathes etc ... so must still be pretty gutsy. The lengths of belt can be bought in quite large diameters as well ... 10mm, 15mm etc To join it without the proper equipment, they just heat up a stanley knife blade and hold with pliers ... press the two belt ends against either side of the blade ... and when the belt is melted enough, they slide the blade out ... and force the two ends together. The resulting bulge is then cut off with side cutters once it has cooled down. There are also fittings to use to mechanically joint the ends ... though I think that version of the belt has a small hole through the centre. There were some pretty fantastic claims as to how strong the join can be ... but I have no idea if they really are that good. If my pool belt breaks before the new one arrives ... I might give it a try and see how good the stuff really is. Type 'round poly belt joining' into google and check out the images. or look at these instructions for joining ... http://www.industrialbearings.com.au/uploads/catalogs/0000000756.1260_polycord_1342150603.pdf Cheers, Roger |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

See how this goes, but if it still slips, some toothed pulleys of similar sizes might be your best option. These don't need to run super tight.  Cheers, Tony. |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Hi Forum Crew. I tried to find my photo years ago of my timing gears ,belt and disc brake assembly,,, but in my thousand photos, Searching for it got just too much. Never mind , I just wanted to tell you I found that I had to turn-up side flanges for the timing pulleys ,as the belt did come off once with catastrophic braking of the blades.. To this day ,I really don't know how it came off ,because bench testing with a electric motor did not seem to make it come off. (So ,, it got put away and I never ventured back ) The disk brake was a bicycle disc, worked reasonably well with the 60 foot fishing line ( very strong line). Sort of did not stop it fast, but slowed it down to be able to be stopped completely during a lull. Motorcycle disc and hydraulic caliber would do the trick--one day ,but gee,,,at 76 I'm sort of running out of them sort of days,Eh? PS, I,ll bet you my photo is in the backside albums ,,somewhere ????? Cheers, mates, have a nice weekend, Bruce Bushboy |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 904 |

Yeah, these would be awesome Tony. I really need a lathe for some of these jobs, would be so much easier. Although with a fresh new belt and the sticky spray for backup, I can't see why I can't get another 12 months out of the system as it is. And the plan is to have the original AC motor running off a Warpinverter before then.  Was that a brake for a wind generator Bruce? Have a good weekend too.  Cheers, Roger |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Yes , Roger. I played around with tails (adjustment, size , Etc) , then one day at the tip shop I saw a $5 bicycle with a disc brake ,so grabbed it and put the disc on my lathe and machined a hub to fit behind the blade hub .. Also , this is where I saw a couple of timing pulleys, belts ,Etc , so here we are discussing those days today !. Wind genie was a F&P set up with Neo magnets(I think ,,or maybe that one got smashed during that period). Anyhow, worked ok ,remember, the F&P interest was really at its height those days, Different blades, lots of modifications to the stator windings and oh course then along came the NEO ideas. Sorry to get off topic , just a chatter box old man ,here . Bruce Bushboy |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 904 |

Hah, yeah that's how it seems to work Bruce. All this stuff crosses over a fair bit and it's always fascinating to wander around a tip shop or scrap metal place and have all sorts of ideas come up for building or modifying gear. Cheers, Roger |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 904 |

Just checked the pool pump pressure on the way in for a coffee and thought it was a bit low considering the sunshine. On closer inspection I saw a stringy looking thing on the ground alongside the motor. Looks like the belt has shed another rib ... it's running on 2 ribs now, 3-4mm. Not really enough.  Hope that new belt gets here soon!!! Cheers, Roger |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 904 |

Was certainly pleased to see the new belt arrive   Cheers, Roger |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1584 |

Geez, you certainly are the cautious type! That old belt looks like it had another good 10 Minutes in it! Spose you can always put it away as a spare . :0) Just the same, Might be a good time to order another belt, just in case. I need to get one about 1200 MM for my little diesel car alternator generator I'm Building. Tried one of the many Subaru ones I have and wouldn't even go round the flywheel. The Commodore ones are fine on the Lister but I could have the alternator about 1.5 M away on this setup. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 904 |

Haha, that is funny ... though it probably says more about my procrastination than my cheapness. I have put it in the bin now coz it is disintegrating completely. Probably a mixture of the belt spray, old age and a horrible life ... but whenever I touch it, the black sticks to everything and I can't get it off. So there's black marks everywhere I've been for the last week ... all around the pool, the door handles and light switches ... even the scrubbing brush. Worse than the kids.  Even acetone won't move it without rubbing hard enough to take skin with it. Good riddance I say. Even acetone won't move it without rubbing hard enough to take skin with it. Good riddance I say.There does seem to be a good range available once you get the right search terms and can work out the sizing you need ... but I do wonder if you might be better off with a timing type belt like Tony showed above, for your alternator setup. Unless you are able to use reasonably large pulleys and perhaps an idler pulley as a tensioner as you suggested earlier. Cheers, Roger |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1153 |

Yep, you sure needed a new belt.  This is the little pump I have been using for the garden 300m away down the back yard, just one of those little southern cross piston pumps, there used to be heaps of these around many years ago, the last few I saw (must be 2 years ago) were snapped up quickly at a swap meet for more $$$ than I thought, a larger one slung over a blokes shoulder walking out to the car park that was about a 1km away, must have been keen to do that. This one has a 1 inch suction pipe from the dam (practically empty) and has a 3/4 inch garden hose on the outlet, runs quite well, with a 1/4HP 32VDC Motor and 5 250W solar panels. It has managed to do 40psi from the creek up to another dam but the belt can slip when starting after a cloud goes past and trying to start under load, don't have any trouble with the garden hose. It will get hot after some time even though it has a fan built in, needs a new set of buckets in the pump too.  A treadmill motor or something similar would be an ideal candidate for these piston pumps. Thinking about tackling a centrifugal pump later, If I could find something that is the correct speed and power to match I would Try direct couple to the shaft. Cheers Aaron Off The Grid |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

As you say, a piston pump is going to be much harder to get moving initially working against full head pressure + friction + inertia of the very necessary flywheel. A centrifugal will be much better matched to a solar application, as it takes almost nothing to start it turning, then it will speed up until all the available power is being used in the most efficient way. Cheers, Tony. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 904 |

I like your setup Aaron, it looks quite practical. Always a good feeling watching them work and knowing they are running off of free energy (if I'm allowed to say that). I don't know much about pumps, but the treadmill motor running my pool pump is supposedly rated at 3hp ... and is driving a pump that had a 1.5hp ac motor. I am using 6 x 250 watt panels in series ... but my gut feeling is that it generally runs at about three quarters of the power of when I run it on ac. If I had more space around the pool ... I really believe another six in series, paralleled with the original six would make a huge difference ... but that is probably overkill. ... so I've decided my next step is to combine the 3kW of panels I currently have, with another 6 or 8kw ... and run everything off a warpinverter Cheers, Roger |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2025 |