|

|

Forum Index : Solar : Need suggestions for my Solar Box idea

| Author | Message | ||||

| MadRat Newbie Joined: 30/09/2008 Location: United StatesPosts: 21 |

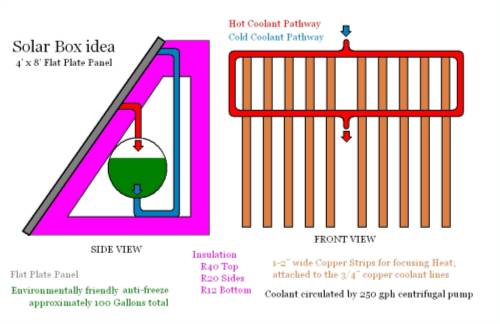

I want to make a test rig for warming my garage during the winter. If it works well I might build more boxes like it. I currently have a few types of insulation, plenty of copper strips, access to sheet metal and a brake, soldering equipment, etc. to carry out the plan. My worry is that this box will get overly damp from condensation or that if the pump overheats it could catch fire or something. My basic plan is to use a flat panel to heat anti-freeze and store the heat energy into a tank that double as the heat exchanger. The tank will have a second set of insulated lines that run to the garage and a thermostat controlled pump in the garage will drive that closed loop to a heat exchanger therein. The pump on the tank will be controlled by its own thermostat so that it shuts off when the flat panel gets cold. The coolant will be a drain-back loop, so it has no coolant in the line if the internal pump is not active. The idea I have it to build this thing on a pallet that can be readily moved around by a fork lift. This should make it easy to detach the lines and store ii under a lean to in the summer. The glass is going to be common tempered window glass. The backplate of the flat panel will be matte black sheet metal. On top of the flat sheet will be strips of copper that tie into the coolant lines. The idea is that copper will leach the heat off the steel. I'm not too worried about the ionization migration between the two because of the limited time they will get used this winter. The internal chamber of the box will hold the tank/heat exchanger. Do I need to use a moisture barrier inside of the chamber? Whats the best way to separate the hot flat sheet of metal from the insulation that surrounds the internal chamber? Lastly, now much water should realistically be moved to get the maximum heat to the tank? Any other suggestions?

Go Huskers! |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi madrat, You will need more coupling between the copper and the plumbing. If you use a centrifugal type pump, then feed the ccolant in at the bottom and the warmed coolant will come off at the top. When the pump stops, then coolant will flow back through the pump and empty the plumbing system anyway. I suggest you check out a commercial solar HWS for some ideas as well. Gordon. become more energy aware |

||||

| MadRat Newbie Joined: 30/09/2008 Location: United StatesPosts: 21 |

Copper sheet is 99.7% pure which gives it better heat absorption and conduction than the underlying copper piping. I can't imagine that the heat won't travel properly because if copper strips were not so effective at moving heat from point A (heat sources) to point B (the chassis) then laptop makers would have real trouble on their hands. :) Go Huskers! |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Copper is a good conductor of heat and electricity. Understanding the heat transfer process require a good grasp of calculus and solving of differential equations. You will need the heat transfer coefficients of steel to copper bar, steel to air, copper bar to copper tubing, copper tubing to working fluid, etc. I hope you solved the equations to determine the required cross sections to get maximum transfer of heat from the incident solar radiation to the working fluid. Gordon. become more energy aware |

||||

| Dinges Senior Member Joined: 04/01/2008 Location: AlbaniaPosts: 510 |

Pst, Gordon, old man...  they now have them new-fangled PCs with fancy FEM (Finite Element Method) software for that, with colourful outputs. Only dinosaurs use calculus anymore they now have them new-fangled PCs with fancy FEM (Finite Element Method) software for that, with colourful outputs. Only dinosaurs use calculus anymore  . Incidentally, it's possible to solve thermodynamics problems using a manual, numerical solving method, without the need for calculus or even matrices. Though of course no one in their right mind would solve such problems using manual numerical methods when everyone has a PC on his desk.... No one, of course, but a Dutchman... (in my defence, I didn't voluntarily do that, it was a course requirement!) And if you insist on integral calculus equations... use math software as MatLab/Simulink. . Incidentally, it's possible to solve thermodynamics problems using a manual, numerical solving method, without the need for calculus or even matrices. Though of course no one in their right mind would solve such problems using manual numerical methods when everyone has a PC on his desk.... No one, of course, but a Dutchman... (in my defence, I didn't voluntarily do that, it was a course requirement!) And if you insist on integral calculus equations... use math software as MatLab/Simulink.

Not really sure the OP needs to even simulate his collectors with FEM. Just a few rough-and-ready rules of thumb should suffice for this purpose, I expect. Some quick heat gain/loss (balance) calculations, and an idea how much energy he needs to heat the area/volume of his garage to a desirable (which?) temperature in a reasonable (how long?) time. Nothing too fancy. To the OP: are you familiar with this site ? http://builditsolar.com/Projects/SpaceHeating/Space_Heating. htm I think you'll find it has all the information you could ever want, and then some more. There are some garage heating projects in there too. Website with a practical point of view. It's not rocket science. Unless you want to squeeze the last % of performance out of your design. |

||||

| MadRat Newbie Joined: 30/09/2008 Location: United StatesPosts: 21 |

I got some previous inspiration from that builditsolar website. GWatPE- You know the more I think about that first suggestion on "flow back" the more I like it. Will have to figure out mass flow through the piping to see how much transfer is possible. Or maybe I'll reduce it off the first t-bar and run some zigzag strips of soft copper tube up the flat sheet strips. That would give me more transfer than I'd know what to do with. One problem that will probably get me in the short term is how cavitation in an impeller pump may kill its lifting power as the water heats up. Anyone run into problems with lift from the pump suffering as the water heats up? Go Huskers! |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

I don't see a problem if the pump is lower than the drum. Gordon. PS. glycol coolants are toxic, so be careful of spills and leaks. become more energy aware |

||||

| MadRat Newbie Joined: 30/09/2008 Location: United StatesPosts: 21 |

Yeah, I've been informed by some fellas here to use "environmentally friendly" coolants. Not really sure 100 gallons is going to be all that affordable at that rate. But then again glycol-based coolants probably are not much cheaper. Haven't priced that one out yet. It was suggested that I simply run a closed loop for the coolant and use simply water in the storage tank. That way I don't have to try to keep pressure in the tank from building up. But then I'd think evaporation during the winter months might be an issue. Go Huskers! |

||||

| Robb Senior Member Joined: 01/08/2007 Location: AustraliaPosts: 221 |

Have you thought about useing air and heating a semi solid mass? This site may be of interest. http://www.solarsponge.com/ Use it to heat a pallet load of bricks incased in insulation maybe. |

||||

| philb Regular Member Joined: 05/07/2008 Location: United StatesPosts: 96 |

MadRat, I have spend the last few months working on my own system. There are a lot of choices out there. Early on, I decided not to use auto antifreeze (ethylene glycol). After a few years of operation, the anti-freeze will probably need to be changed. Stagnation in the summer, when the temperatures can become excessively high ,are the biggest culprit. You can't pour it out unless you want to rid the neighborhood of excess dogs and cats.

In the US, you can use "RV anti-freeze", which is propylene glycol. It's non-toxic and available from the major retailers. Walmart stocks it year round in the RV section. Use just enough to prevent the system from freezing. Since I see "Go Huskers", I assume you are in the central US, so you do need some type of freeze protection. Have you thought about using a drainback system? No anti-freeze, just water. Of course, that won't work if you have a high mineral content water source, like mine. The system I have chosen uses propylene glycol running through the collectors. 3/4" pex collect the hot water and 1/2" pex manifold is wrapped around a hot water tank to serve as a preheater. "Anyone run into problems with lift from the pump suffering as the water heats up?" A good pump, say, a Taco or Grundfos that is made for this application and sized correctly is the best insurance against this. Pump manufacturers give the specs on their pumps. Homepower magazine gave and compared different pumps in an article recently. The url is listed on built it solar site. Also, you will need a coin air vent and expansion tank if you use a closed system. philb |

||||

| MadRat Newbie Joined: 30/09/2008 Location: United StatesPosts: 21 |

I built a test box for a piece of glass 85" by 46", but this one is strictly for moving air. It will be attached to my parents house rather than my own. I figure the way their garage has windows on the south side I can rig a fan to start up at above 100ºF and then blow cold air in which should force the warm air out. A louver will shutter the flows when the collector is cold. The box is made completely out of a mixture of 24/26 gauge mild steel, painted the inside black, and surrounded the perimeter with R5-rated 3/4" foil-backed insulation. The unit without glass weighs around 60 pounds. With glass installed I think it grew to 80 pounds. Only going by best guess as imho its just barely light enough for one man to handle. Due to limitations of my 48" wide sheet stock the 46" wide glass required me to make a much more complex box than if I could have done it in one piece. But after only about 8 man-hours its nearly ready to mount in place. I hope to get it installed within two weeks; have to figure out the electrical end of the project first. This should give me a good idea of the potential at least for the short term. This will also help me decide whether its worth the trouble/material to go with the 85" by 46" glass or to dig out the 85" by 42" glass panels. Go Huskers! |

||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 224 |

MadRat, Here's another site with some relevance I think. www.sunlizard.com.au "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

I actually already did this 30-something years ago. Two changes will make this happen: First, in your picture, eliminate the accumulator (tank). Just run a loop with a fan-forced heat exchanger inside your garage. Thermo-syphoning will take care of circulation. As the coolant heats, it becomes less dense and rises against gravity, forming a self-pumping loop. Second, use filtered waste car oil in your system; it's free. The oil will hold several times the heat of anything with water. Just make sure there are no leaks, because very hot oil in air will flash and burn violently. My system used a dump valve with a sensor mounted atop the unit. If the temperature rose over 400 degrees (paper ignites at 451 F), the oil dumped into an insulated accumulator held in vacuum in the shadow of the thing inside the garage. It never happened, by the way; just a precautionary deed. The entire system used approximately 4 gallons of used oil. I was in Florida and didn't have to put up with any extreme temps, but in cold areas, a closed system could easily employ a larger volume of oil and a larger-capacity accumulator (storage tank). If you do this, just make sure the system is full with NO TRAPPED AIR. A sight glass used for high-pressure refrigerant mounted at the apex of the system might come in handy to make sure you're not building a potential bomb. Drain the system in the summer! Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||