|

|

Forum Index : Other Stuff : Grid storage using lead acid?

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5116 |

OK, thought experiment, without getting into politics, climate change, etc, etc, please. One issue with moving a nations power grid to use more renewable sources is storage. Pumped hydro is expensive to build, plus depending on location can be devastating to the people who live in the flood plain. Battery farms are also expensive, though they do pay for themselves pretty fast, are perfect for base load and are very efficient. They are using lithium based batteries, expensive, not easily recycled. Why use lithium? Whats wrong with lead acid. Weight isnt a issue. LA batteries are more rugged, wont catch fire, are cheaper to build, and much cheaper to rebuild/recycle. What I'm thinking, would it be viable for a battery farm to use lead acid batteries, and include their own rebuilding facilities. Once a battery reaches end of life, it can be rebuilt on site or at a central location, and put back into service. Rebuilding a LA battery is easy, cheap compared to buying new, see... You Tube link When I worked for Telecom we had big 2v cells in glass containers. These would last over a decade and were then send off to be rebuilt. I feel lithium battery technology is a trend that's not really the best option is many cases, especially if weight is not a issue. Thoughts? The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| phil99 Guru Joined: 11/02/2018 Location: AustraliaPosts: 2582 |

Agree, where weight isn't an issue FLA cells are viable. Not quite as efficient as lithium but more efficient than pumped hydro. As you point out capital costs would less than lithium and dramatically less than pumped hydro. The Snowy 2.0 project will never recoup its immense cost, and won't be delivering power for some years yet. For a large battery farm onsite plate reprocessing would give an indefinite life. |

||||

TassyJim Guru Joined: 07/08/2011 Location: AustraliaPosts: 6266 |

I also agree. LA made for stationary use don't need all the extras that mobile batteries need to stop them rattling apart. They will need a bigger shed and that's about all. Jim VK7JH MMedit |

||||

| greybeard Senior Member Joined: 04/01/2010 Location: AustraliaPosts: 172 |

Not disagreeing with the thrust of the argument just like to point out that from my experience with Telecom LA batteries, they were basically kept on float charge with scheduled boost charging. ie not cycled unless there was a mains failure. Granted my experience was from about 40 odd years ago and from the PMG LA manual which described how the batteries were to be managed. This was all pre mobile phone era so I don't know if anything changed for mobile phone tower setups or even what battery technology they use. What impact cycle use compared to float has on LA battery life obviously is part of it. Suppose there would need to be a cost benefit calc done to be sway an argument either way. Rod |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1152 |

I agree with FLA for large stationary storage, Years ago (somewhere here on the forum) I said it would make more sense to keep light weight power dense batteries for portable devices phones cars computers power tools etc, and use FLA for storage, since then battery tech has moved on and still developing other types. According to a few that have built and maintained pumped hydro they said it was about 50 percent efficient at best. Long time ago My Oldman and I had the job of removing a few of the old telecom battery backups, they were mostly 2v cells some 6v, mostly 200Ah Exide the older ones were Dunlop all in plastic cases, some dating back to the late 80's early 90's, must have gathered up about 6 ton of them over time. These big Grid battery installations will be wanting the performance to be very efficient, especially as they want maximum profit and be charged from the grid during the day and sent to the grid at night There is a mob ( have posted this on the solar forum) determined to build a big storage battery Just down the road from me, Bremerbattery, Quote "Battery Size: 850MW/3400MWh battery would store rooftop solar, and other renewable energy" Massive objection to it and rightly so, I suspect it would be a Tesla battery, (Disgusted with it) Not even an Australian built battery as we don't build stuff here even though we got the opportunity. At the moment I think I'm out of the Exclusion Zone, or until the increase that more Km's, then we are screwed. So the question, How big and heavy would a 850MW/3400MWh battery in FLA? @greybeard  yes agree they were on float most of the time, one of the battery charges I has has a switch on the front says FLOAT - GAS while the later model charger says Float 1 Float 2 boost, this would be in the book as you said. yes agree they were on float most of the time, one of the battery charges I has has a switch on the front says FLOAT - GAS while the later model charger says Float 1 Float 2 boost, this would be in the book as you said.  Cheers Aaron Off The Grid |

||||

| mab1 Senior Member Joined: 10/02/2015 Location: United KingdomPosts: 239 |

I was thinking both FLA and pumped storage were around 60% round trip efficiency, but agree that the 'impact ' of pumped storage is large. Forklift (traction) batteries would be better than telecoms standby batteries (AGM). AGM are fine for deep cycle in principle, but are designed to have a minimum of moisture in the matting and that limits their life in rapid deep cycle situations(although you can add water to them, effectively turning them into flooded and extend their life), but AGM might not be as easy to rebuild at end of life. Part if the argument for lithium I guess is the high charge/discharge rate meaning that they can take over some of the very short duration, high peak current grid stability duties, but I suspect the decision to go lithium is based on:- higher round trip efficiency makes for a better business model, and 'image' (politics) - lead acid is old tech and lithium is 'the future'. |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5116 |

I think if we used a battery designed for this application, and kept it within the 60% to 100% state of charge, we could end up with a long lived battery that was easy to rebuild, and could be manufactured in your own country. The price would have to be cheap enough to encourage private investment over Lithium based options. Locally manufactured using common materials, nothing exotic, and easily recycled. I think the public would be on board for these reasons, plus the increased safety. After all, its the same technology that's been starting you car for close to 100 years. Regarding efficiency, they are not that bad, I've read 80 to 85% efficient compared to lithiums 90 to 95%. Not as good as lithium, but advantages in other area's. I guess it depends on the price of the source of the energy. For example, I run solar and LA battery storage. I have 420Ah in battery ( about 20kWh ). For the same money I could have bought about 140Ah of lithium. More efficient. But I have so much solar on the roof it doesn't matter, the batteries are fully charged by 10am, so I would gain nothing by having a more efficient battery, its cheaper to add more solar and a larger less efficient battery bank. Plus I do have more Ah if I dont mind pushing the SOC below 60% Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1152 |

This time of year my batteries are charged by 9:00am a little later if there is some cloud cover, and I don't use all the stored energy in one night, most of us don't and its how we run the grid tied system wouldn't make maximum profit doing it like this. For the grid tied battery they want a full cycle, so using the entire capacity over night would be there best profit, and a few percent better on a massive battery adds up to $$$ in power sold. I guess if the battery is sized for its expected use the same as we use these at home, but that would be big.  Its likely that regardless of battery type it will foreign owned, and they will make everyone pay, that includes us.  Edited 2024-12-08 07:37 by Revlac Cheers Aaron Off The Grid |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1435 |

Well as more companies are using electric forklifts the waste of of traction batteries as they need to be replaced everytime they are rehired out again means the land fill has 1,000's of them wasting away. With my traction batteries on the house array a 1.9Kw solar array has meant the amount of times we have had to run the genset this year can be counted on one hand  Like wise for my shed array 6 off 190 watt panels has revived the traction battery and even with a bar fridge going 24/7 the batteries are on float by lunchtime most days even after I have been machining for hours too. |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1152 |

The EPA would be all over it like a hot rash if they went to landfill, especially in QLD, not supposed to cart forklift size batteries or bigger without all the proper signage licence etc, or big fines and jail time last time I checked. regs for other states may be different. A big grid battery would also have to comply with the EPA rules. Cheers Aaron Off The Grid |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5116 |

No need for LA batteries to go to landfill, they get good money at the metal recyclers. In the past I've recovered 10% of the buy price back from the metal recyclers. I go to a lot of the local farm clearing sales, the bidding on a pallet of dead farm equipment batteries will got for $300 easily. So the bidder is expecting to make more than that at the scrap metal dealer. A LA battery can be pulled apart, rebuilt, and put back into service with no special tools, unlike lithium. In Australia we still make LA batteries, and we have all the resources. Makes sense to build our own grid storage systems, keep the money here. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| phil99 Guru Joined: 11/02/2018 Location: AustraliaPosts: 2582 |

A grid storage battery can take advantage of the economy of scale. The plates would be big and all identical size so automated reprocessing would be practical and cheap. From what I have read submarine battery plates are typically 54"H x 21"W but can be up to 6'H x 4'W. For grid storage the optimum size might be even bigger. Large LA battery mathematical model:- https://sms.wgtn.ac.nz/foswiki/pub/Main/ResearchReportSeries/mscs03-08.pdf |

||||

| Clockmanfr Guru Joined: 23/10/2015 Location: FrancePosts: 437 |

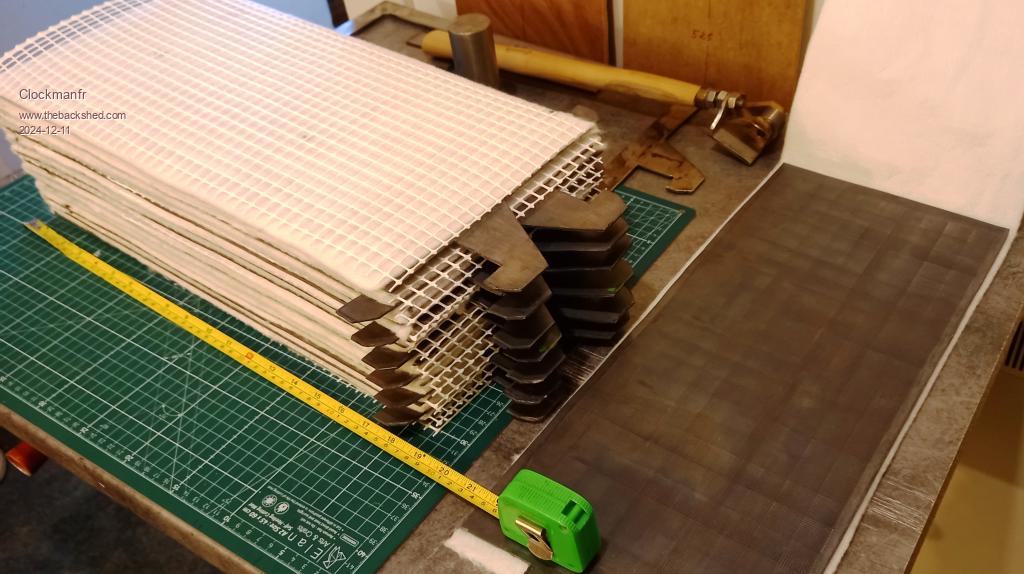

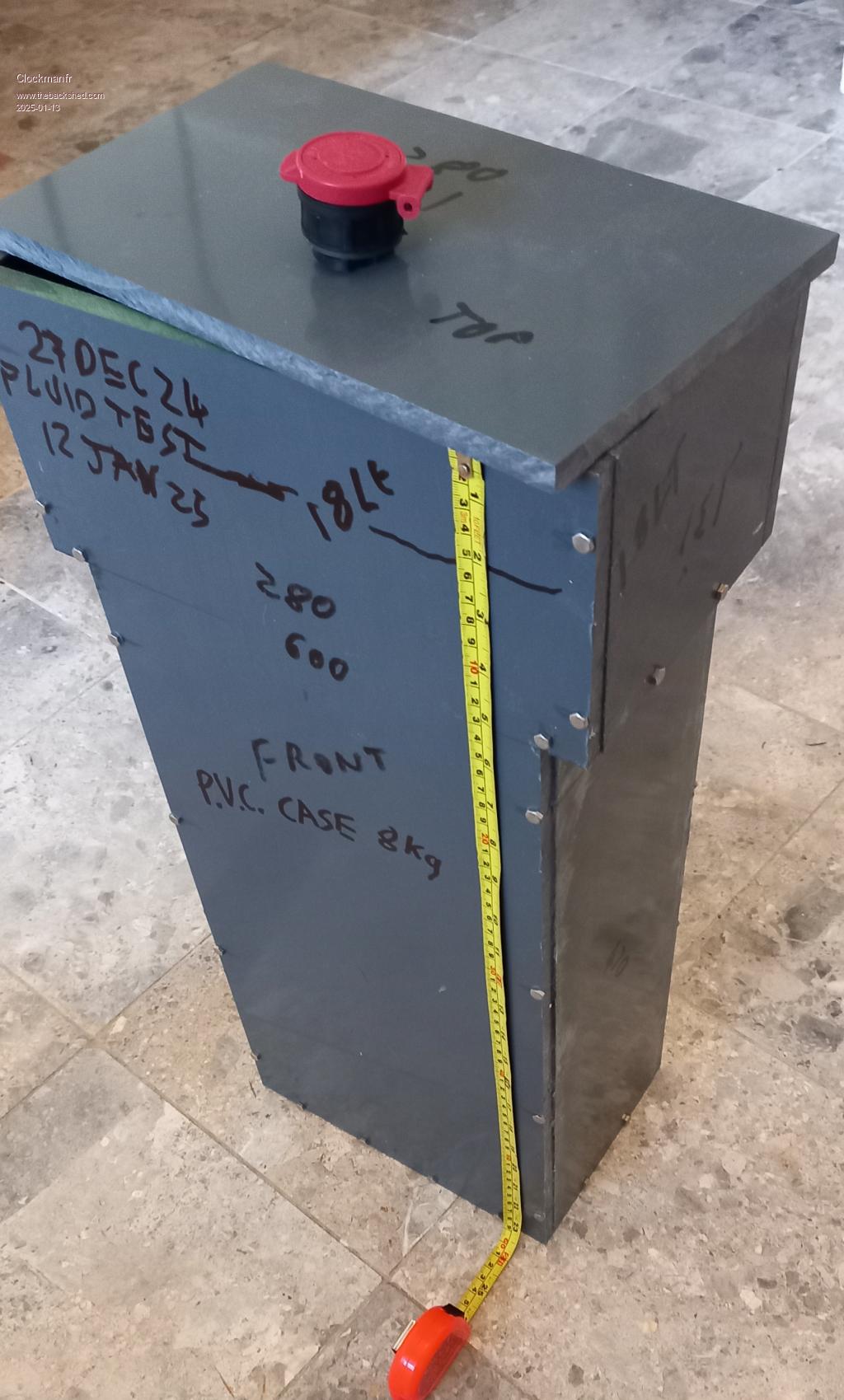

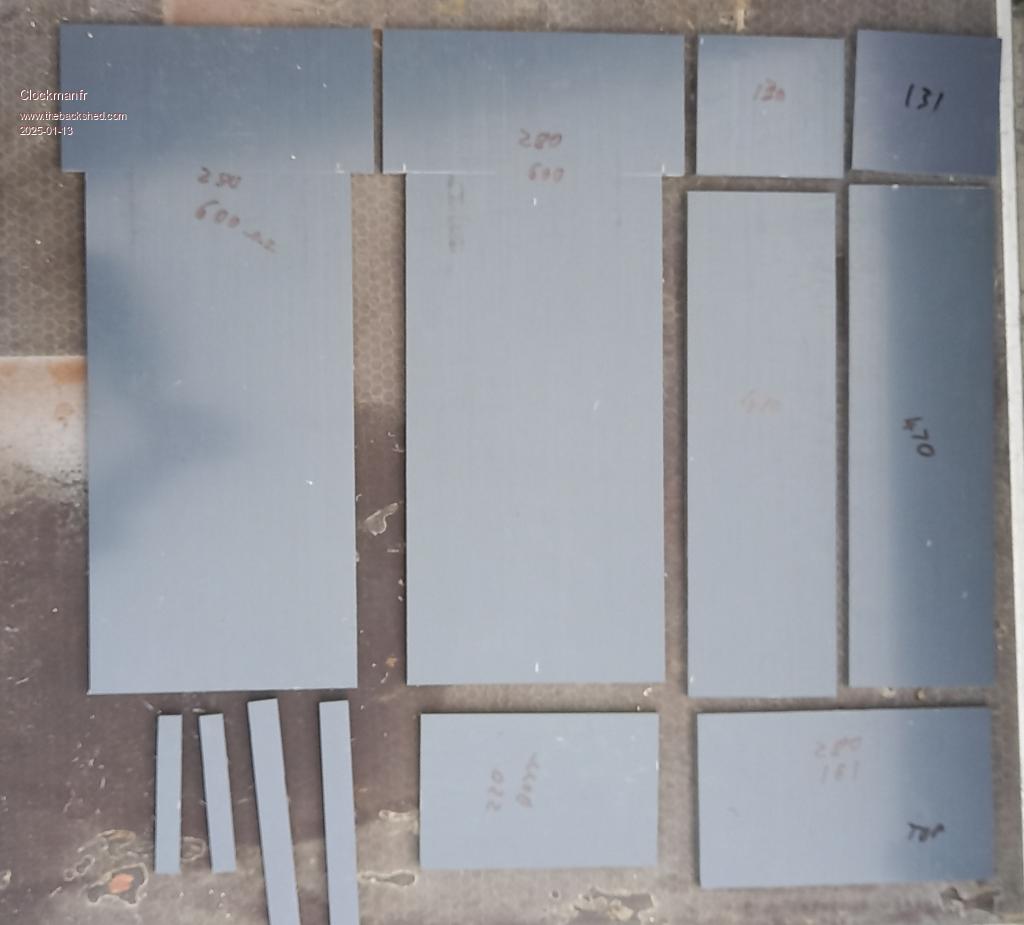

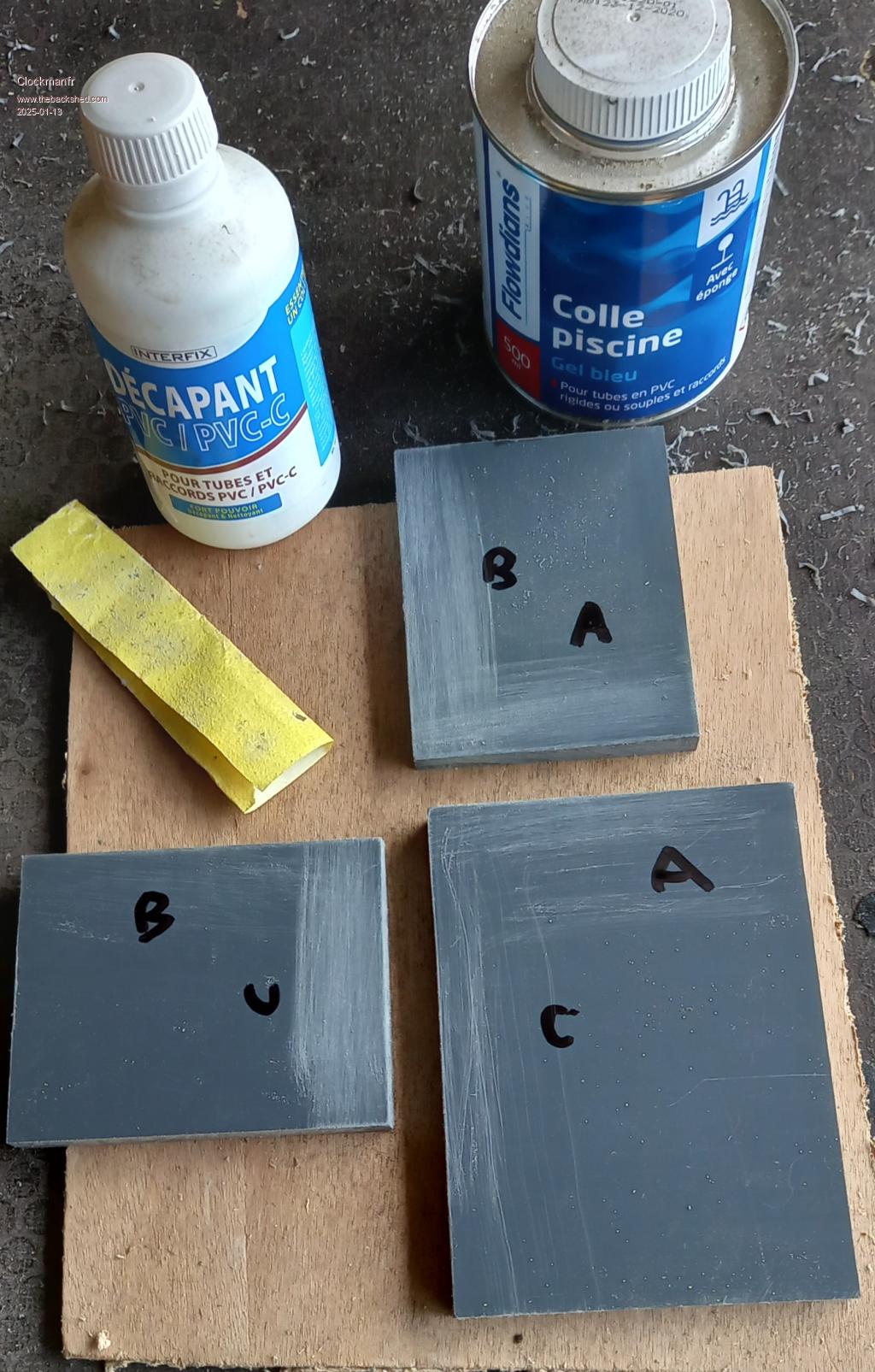

2 years later still slowly working on 60kg, 2v lead acid cells at about 450 to 550ah, using the PLANTE concept but a very modern design that is designed so anybody can make. Plates design good and R&D finished. Case design now completed and case components under stress and assembly testing. Internal lead bus bars design concept good.  Will post stuff soon. Everything is possible, just give me time. 3 HughP's 3.7m Wind T's (14 years). 5kW PV on 3 Trackers, (10 yrs). 21kW PV AC coupled SH GTI's. OzInverter created Grid. 1300ah 48v. |

||||

| Godoh Guru Joined: 26/09/2020 Location: AustraliaPosts: 529 |

Wow Clockman, I remember you writing about that project when you started the process of designing an making the cells. So you are still at it. Good luck they look impressive so far Pete |

||||

| Clockmanfr Guru Joined: 23/10/2015 Location: FrancePosts: 437 |

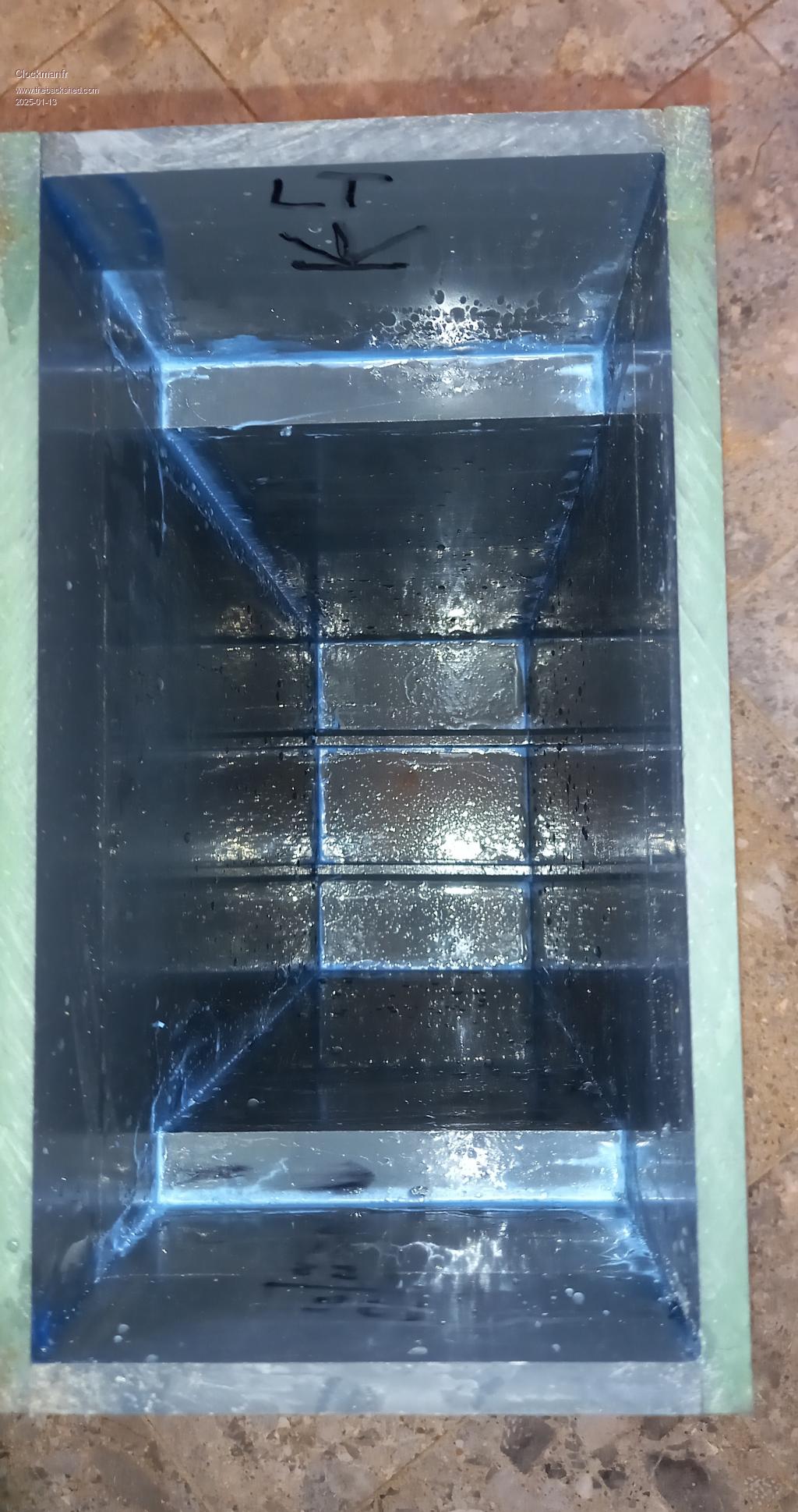

UPDATE ..... I started this project in late 2021, i have other projects so this has been delayed, but finally i am getting their, oh yea. The Case of the NEW MODERN PLANTE lead acid battery. Over Christmas the case has been undergoing fluid testing. All good. Remember folks, this is a project and concept that will be official published, tech drawings, designs and jigs design, and loads of colour photos, for anybody on this Planet to make their own. Designed and Now making the steel moulds so the internal plate joining lead bus bars can be easily constructed/cast. Questions from David, and my Answers..... Q. Will the plate assembly be easy to lift out to clean sheddeed material from the botton or will the thickness and construction of the plates avoid anything falling to the bottom? Yes, the assembled plates will be easy to lift out, as the the top of the battery will be removable. The negative and positive terminal post will be 10mm stainless steel, so undo the 2 stainless steel nuts and shims and the case top just lifts off after the 12off top 4mm stainless bolts are removed. The top is sealed with a tested silicone that can be cut with knife. The plates sit on the case bottom strips that are 25mm to the sump. They also sit on the intetnal lip and the lead bus bars. These plates are solid so the lead dioxide active surface is formed as the battery is worked. They are NOT a grid matrix with a impregnated lead dioxide. Q.... Do you see any advantage in having an air or fluid pipe going to the bottom of the battery for electrolyte circulation as I have seen some commercial batteries or do you believe that proper charging and equalising takes care of that? No, each of the 13off SOLID rigged plates are in a thick geoyextile felt, non woven, sock. I have allowed 5mm internal clearance for the plate sides, and the plate faces are not tight against each other. Its a proportional relationship between amount of lead plates to Acid required and circulation.      Everything is possible, just give me time. 3 HughP's 3.7m Wind T's (14 years). 5kW PV on 3 Trackers, (10 yrs). 21kW PV AC coupled SH GTI's. OzInverter created Grid. 1300ah 48v. |

||||

| zeitfest Guru Joined: 31/07/2019 Location: AustraliaPosts: 570 |

I think there is a device that would work well. It is a combination cell of existing technologies, I don't know if it would be cost=effective or not. It would be good to see a bbq running om hydrogen though !!! The cell has three electrodes. It has 1) a hydrogen evolution electrode, to evolve hydrogen, as used in an electrolysis cell 2) a lead/lead oxide electrode, to store power, as used in a lead acid battery 3) a methanol electrode, as used in a DMFC ( direct methanol fuel cell ), to act as counter electrode for the lead/oxide electrode, Initially the methanol electrode is disconnected. When external power is available it is fed to the hydrogen and lead electrodes, used as a combined electrolysis / storage cell. Hydrogen is evolved and lead oxide is formed at the lead electrode, standard lead/acid. 2 H+ + 2e -> H2 PbSO4 +2 H2O -> PbO2 + 4H+ +2e + SO4-- After the lead electrode is fully charged, the methanol electrode is connected and the hydrogen electrode is disconnected. The combination of the lead electrode and methanol electrode then acts as a power source, mainly provided by the lead/oxide discharge reaction, using the methanol electrode as an electron source. PbO2 + 4H+ +2e + SO4-- -> PbSO4 +2 H2O CH3OH + H2O -> CO2 + 6H+ +6e Overall (a little) methanol is converted to hydrogen and CO2, but in the process a lot of say solar/wind energy is stored and made available. How about a free lunch Twiggy ????  |

||||

| zeitfest Guru Joined: 31/07/2019 Location: AustraliaPosts: 570 |

Sigh... Ran the idea past commercial entity. Apparently a lead oxide/sulfate electrode needs a conductive platinum filler to be viable.  At 3% by weight... a car battery weighs say 60 Kg.... Wacko !! I'm rich !! At 3% by weight... a car battery weighs say 60 Kg.... Wacko !! I'm rich !! Gosh now now I'll be able to buy a Maximite from Altronics ($125 ?), and set up a web chat site to discuss Creen Alternative Methodologies. Actually thanks to British Commonwealth connections, I have a contact who is closely connected with Nigerian Royalty and they just need someone to help by setting up a bank account and.... |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2025 |