|

|

Forum Index : Other Stuff : Kaplan Turbine

| Author | Message | ||||

| Frank Newbie Joined: 13/10/2010 Location: Posts: 5 |

Hi there Bob, Thanks for your reply, it was interesting reading how your Grandad did his wheel. We've been living on our 40 acre property in NQ for 22 years and have used alternative power all that time, when we did enquire about getting mains power here, it was going to cost as much as the original price we paid for the land. I built my wheel out of mostly 2nd hand materials, note the paddles that are old aluminium road signs.(No I didn't go round at night helping myself from the local roads, these were bought at an auction for $100 for a pallet load of signs. Great as they don't rust!) I got the F&P motors from old washing machines at our local friendly dump, ($10 each or free if the guy was in a good mood.)Originally I used old push-bike chains and sprockets, but these were too light and I had to up-grade to heavier-duty. All up my wheel has only set me back about $1,600, but of course that doesn't include my time, which was a lot. (I'm a carpenter and not that good at welding.) Regards Frank. |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Frank It is a really good job, and from the sounds of the output it would be enough to run the whole house, I like your Idea of lifting it up during floods and service, should make it pretty well fool proof.Its a shame that we don't have more of this happening along the coastal fringe as the little creeks have a lot of potential, with a bit of solar and a few batteries you can be fully independent. Grandpas wheel was a wooden construction you would have loved it being a chippy, just a box of coach bolts and an old shaft he picked up at a clearing sale, he made his own pulley too from wood, I wish I still had a picture of it to show you. It looked like a paddle wheel off a paddle steamer but all wood, it lasted for nearly eighty years, till the flood got it. I still have the old generator that was on it, a 32 volt 60 amp at 1600 rpm, it drove that generator with no worries. It even charged the lighting batteries at the dairy about 200 yards away, so they had light to milk the cows in the winter, dairy farmers are a tough lot. He made a fridge out of wood and insulated with saw dust from the mill, it had a 32 volt belt driven compressor that chugged away for years, I don't know what happened to it in the end. I can remember the home made ice cream grandma made in it as a real highlight to my life. Kids these days arn't lucky enough to experience that. A funny thing about it was it seemed to attract the fish in the creek as you could see fish in the outrace pond all the time, so we had fish to eat as well. All the best Bob Foolin Around |

||||

AMACK Senior Member Joined: 31/05/2009 Location: AustraliaPosts: 184 |

Hi Frank, Do you have a photo of the set up you have, would be good to see it. I like the idea of under shot wheels but we have just had alot of heavy rain and the little creek was not so small. It is normaly about 1.5 mt deep and about a 1mt wide but when I looked at it it was about 20 mt wide and about 4mt in depth. I am not sure I would like to be that wheel. AMACK *Note to self 1. Make it thick 2.Make it heavy. 3.Make it stronger than it should be. 4. Don't rush the first job as the second job will cost more and take mor |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

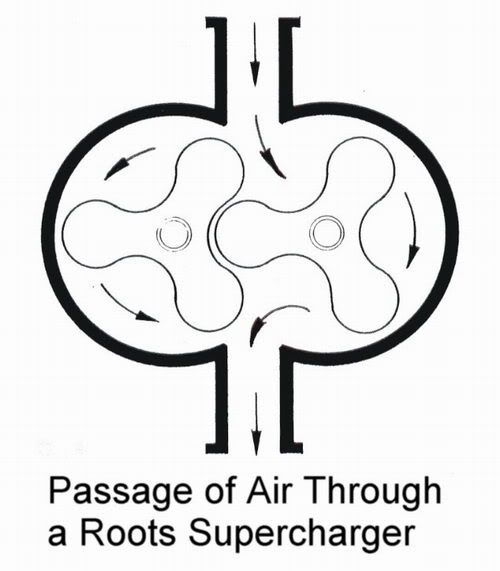

Thinking a bit more about the problems of efficiently extracting power from a high volume low rise hydro, an original idea has just suggested itself. How about a Roots air blower used as a low pressure low speed water turbine?

Superchargers are sized and have an exact rated displacement per revolution, and should have an almost 100% efficiency in in converting the potential energy of a falling mass of water into rotational energy. I can only forsee two potential problems, corrosion/grit blasting, as the exposed internal parts are always aluminium, and total jamming from solid objects ingested into the turbine. But if the water is extremely clean, as from a natural spring, it may be workable. Smallest units such as the Toyota SC12 and SC14 have volumes of 1.2 and 1.4 litres per revolution. Much larger units such as the well known GM 4-71, 6-71 and 8-71 have displacements of 4.2, 5.3, and 7.1 litres per revolution. What do you guys think ? Cheers, Tony. |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Warpspeed The roots blower idea is prone to jamming with very small clearances between the rotors, however my friend made one with two star shaped rotors fabricated from steel, it had a 1/4" clearance to the outer case, but with the high viscosity of water as compared to air it worked with little leakage at reasonable revolutions, the inlet pipe was 10 inches and the outrace pipe was 8 inches with several meters fall for good suction. He had a 1/4 inch mesh filter on the inlet to keep big stuff out but it passed sand ok. The outer case was made from 12 inch bore casing cut and welded into the figure 8 casing with timing gears in a separate housing to prevent water ingress. It ran a large 36 volt generator to a battery storage with a throttle valve on the outlet pipe to prevent over charging. All the best Bob Foolin Around |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Standard diesel blowers are set up pretty loose anyway, and a worn out one would have even more clearance. It would also be possible to skim the outside diameter of the rotors down in a lathe to provide greater clearance. I have never heard before that this idea has ever been tried. A large area fine mesh screen as you suggest would be a good idea too. Where the flow volume is really low, I would think this has potential to be considerably more efficient than a simple turbine wheel. Cheers, Tony. |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Warpspeed The biggest problem with using a diesel engine one is the rotor to rotor clearance is a bit close and keeping the water out of the timing gears as it is all close coupled. All the best Bob Foolin Around |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5036 |

How about a gear pump? I have a couple, one small and another a bit larger. The smaller one was rigged up to a 24v scoota motor and I used it to fill the header tank at my last place. The bigger one will go onto a little 1hp Vikers petrol motor I have.

I played around with superchargers when I was a younger fella. The supercharger I used was a Japanese type with Teflon rotors and a electrical clutch. I fitted it to a Datsun L18 motor.

There was a far bit of leakage around the rotors, you could hold the front pulley still with your hand while the motor was running and the blower clutch disengaged. This type of blower had pretty good seal on the bearings, and a separate oil sump for the gear box. It ran under manifold vacuum, meaning the seals were good for 10 or more PSI. Maybe it would be suitable in this water driven application? It was a Toyota supercharger, if you search for a Toyota 1G Supercharger, you'll find heaps of them. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

If the basic concept is sound, then something might be done with bronze or stainless gears and plain sleeve bearings. It just seems to me that if there is not a lot of water volume or pressure head, even a leaky old positive displacement turbine might prove better than a simple open rotor. Cheers, Tony. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

If the basic concept is sound, then something might be done with bronze, plastic, or stainless gears and plain sleeve bearings. A gear pump is even simpler, and simple is good. It just seems to me that if there is not a lot of water volume or pressure head, even a leaky old positive displacement turbine might prove better than a simple open rotor. Cheers, Tony. |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Glenn The gear type would work but require a lot of pressure as I have used these gear pumps as hydraulic motors in the past, but lubrication was guaranteed, in water they wouldn't last long if the bearings weren't greased every few hours. The supercharger I know as i have several in the shed left over from a gas turbine motor we designed, a good little unit but once again wouldn't last long in a water environment. The concept has limitations as the pressure acting on the swept area of the input side can only produce energy from 1/3 of the swept area as the center is rotating against the flow it takes one side to equalize that and the other side is the energy collected. It will work in a large device with low pressure flow however as my friends one demonstrated. The better one would be the single pin wheel turbine, as it acts as miniature overshot wheel but with no timing gears or seals required. As Warpspeed said simple is good and you cant get much simpler than a single captive rotor, its only disadvantage is that it needs to be at the outlet end of the pipe to avoid back pressure whereas the twin rotor can be at the inlet and use gravity suction to some extent to augment its action. I will do a mud map and try to post it to show what I mean. All the best Bob Foolin Around |

||||

| Air Bender Senior Member Joined: 25/01/2011 Location: AustraliaPosts: 206 |

Warp-speed this is something i daydream about. Siting in a shed beside a stream with a big old fashioned water wheel atached with a large shaft running through the ceiling that i couple and uncouple machinery to at my leasure. All the best Dean. |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Dean It shore would be nice to have a creek like that next to the workshop, but from past events it could be a real washout. My grandfather made one years ago and it was going well until the stupid idiots at water recourses cleaned out the creek and made a water race out of it and washed everything away, including the creek flat paddocks, they are nearly as stupid as politicians, but worse in reality because they have university degrees to back up their stupidity. All the best Bob Foolin Around |

||||

| Barry T Coles Senior Member Joined: 30/07/2009 Location: AustraliaPosts: 109 |

Hi Bob It looks like the water resources in QLD have trained at the same University of stupidity as those here in WA. I work for the Water Corporation, WA's supplier of water to the public & we are governed by the Department of Water (water resources), if I was to write about the stupidity I have seen over the last 40 years it would turn into a set of encyclopaedias. The decisions made by these people come mainly from environmental types who have absolutly no training in Hydrography, I'm sure most of them think water will run up hill unaided cos thats how it gets to thier taps

Ah well 2 more years & I retire

Cheers Barry I need to learn from the mistakes of others. I dont have the time to make them all myself. |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Barry Don't rock the boat now, too much to loose. It is a problem with departments like this that impose the supposed solutions on the masses with training from people in UNI that have seen a river and creek in a film or on TV, but not lived with them over a period of time. All the best Bob Foolin Around |

||||

| Air Bender Senior Member Joined: 25/01/2011 Location: AustraliaPosts: 206 |

What has happened to the days when engineers worked there way up from being stokers and if they were prepeared to take on a bit of forther study could work there way up. I had the privalige to work under a couple of these guys who started there time in the merchant navy and then later in life they moved into the proccessing industry. I have found it very sad to see young guys come out of university and then breaking down once on the job. There has to be a better way. |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Airbender Schooling is important but only if it is by a person who knows the practical side as well, with years of experience, most teachers these days teach what the book says and the book is written by an academic with little or no practical experience, that is as good as a hip pocket in a tee shirt. In the past I have employed these types and found to my disappointment they where worse than stupid because they knew it all, but it was mostly wrong, and as they knew it all they couldn't be retrained. in certain fields that are theory based it may be OK to learn all from the books as a starting point, but my experience has been that most you learn you never use again, so it is a waste of time, hard learned practical knowledge under a master tradesman is the best education, with a enough book knowledgeably to fill the gaps. All the best Bob Foolin Around |

||||

| sjstreet Newbie Joined: 26/02/2011 Location: Posts: 1 |

Barry, About that Dethridge wheel, do you know what power it can generate? Could it run (say) a trash removal system upstream with the geared-up rotational energy. What rotation speed does it do compared to flow? Regards, Stephen |

||||