|

|

Forum Index : Other Stuff : Fixing the ride on mower

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Couple of years ago I visited forum members Bob's ( VK4AYQ ) place. Bob has a light airplane grass air strip in his back yard, and I asked him how he kept the grass cut? He said he used a ride on mower, and something along the lines of "It relaxes me, gives me time to think". I guess it would, there would be many hours involved. My own place has about 8 acres of open grass, and in the past I've paid a local farmer to mow it with his tractor-slasher, which takes a couple of hours. A few weeks ago the grass was getting long, a couple of feet high in places, and needed to be cut again to keep the fire risk down and discourage snakes, and I decided to do a Bob and mow it with my ride on mower. Spent about an hour a day, and after the first few days the mower started to complain with a noisy bearing on the clutch driven cone drive shaft thingy. So decided to replace the bearing and see what else I could improve.

The mower is a Cox, seen here on the right. It uses a cone clutch drive system, very simple and reliable. In the past I lifted the mower a few inches so it can cut long grass, mow down tree's, etc, and its been pretty reliable, even if it needs a cup of oil in the engine before every shift. It was pretty slow, I could walk faster, but it was tough. The other mower is a Murray, twin blade, hydrostatic drive and good for a lawn, but no good on the rough stuff. Took a bit to get the drive shaft out, everything was old and seized, needed a can of WD40 and hammer to free it up. While I had the drive shaft out I looked at the clutch cone, then looked on the internet, and worked out the cone had worn down to about half its original size. That would explain why the Cox was so slow. A replacement cone was about $140, which I couldn't afford, so decided to make my own. The cone looked to be made from 3 layers of compressed fibre material ( probably asbestos! ), the outer two were soft, and the inner hard. So I layered up some sheets of Masonite and dense fibre board to the same thickness as the original cone, and machined it into a cone of the same angle as the original cone, but about twice the diameter. Then glued it all together with some wood glue ( not needed as I found out later ). Also drilled a dowel hole to match the original cone.

Assembled, you can see the original cone to the right.

And here it is in place, photo take after its been in service for a few hours.

While I was at it I replaced the 9 tooth drive sprocket, missing a couple of teeth, with a new 11 tooth. And of course replaced the noisy bearing.

The result. Well its a lot faster than it once was. Its even quicker than the Murray, I would have to jog to keep up with it. So far have mowed about 5 acres with the new cone and it shows no signs of wear. The sheets of Masonite have delaminated, but this doesn't seem to affect it. Back to the mowing, took about 5 hours all up, spread over a few days. And yes it was relaxing, I'm even looking forward to the next time it needs mowing in a few months. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| norcold Guru Joined: 06/02/2011 Location: AustraliaPosts: 670 |

Bloody grass, always growing. I moved away from rideons (they seem to be always in need of repairs) when I scored a little Kubota 28hp diesel garden tractor with a 4ft slasher. The Kubota being very manoeuvrable with its hydrostatic transmission but not as good as a rideon of course, just a matter of keeping the slasher blades sharp. Job is not far from that produced by a rideon, with slashers being almost maintenance free. But the best mowers are the resident wallabies & roos(Missus is a fanatic wildlife carer). The released wallies hang around and breed, they know their on a good thing, except you`ve got to fence in young fruit trees and protect irrigation sprays as they`re a destructive lot. But I wouldn`t encourage the Missus too far in this respect, fanatic is an understatement. We come from the land downunder. Vic |

||||

| paceman Guru Joined: 07/10/2011 Location: AustraliaPosts: 1329 |

Maybe a couple of sheep is the answer. They'd probably leave the trees alone too - and lamb chops each year (err - maybe mutton chops!). |

||||

| Dubyagee Newbie Joined: 15/06/2007 Location: United StatesPosts: 21 |

I have seen old truck axles modified where the input yoke was facing down, a blade attached and was modified to tow behind a truck, jeep, tractor, etc. The blade was powered by the wheels and the speed depended on the gear ratio. Was a pain in the turns but cleared fields of grass in no time. Regards, Dubyagee |

||||

| dwyer Guru Joined: 19/09/2005 Location: AustraliaPosts: 575 |

Glen The easy way is mow the grass is get a cow as l have 3 cow and two calf on nearly 6 acres land and my land got no grass left so now got to buy some cattle feed every week maybe if you like to borrow one of my cow for awhile . just send PM  |

||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Glenn, Great repair job! I bet you can fix anything bar the crack of dawn or a broken heart! Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

Glen & Crew Here's mine: Here's an out-of-focus picture of my "expensive-green-paint" (John Deere) ride-on mower. I have every good intention of building an electric ride-on mower out of a golf cart chassis. The 'cutters' will be high-speed motors direct-driving braided-wire weed-eater strings. I plan on recharging things with one of my VAWT windmills, which I intend building very, very soon! . . . . . MAC Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| marty57 Newbie Joined: 24/11/2019 Location: AustraliaPosts: 1 |

hi where can i get 11 tooth drive sprocket to fit cox ride on thanks |

||||

| nambuat Newbie Joined: 19/03/2022 Location: AustraliaPosts: 5 |

|

||||

| nambuat Newbie Joined: 19/03/2022 Location: AustraliaPosts: 5 |

Interesting fix. Can you reveal what sizes you made the new cone please? Angles used Would Fibreglass resin work for the lamination process? My metal lathe is u/s at the moment so I'll have to use the wood lathe Any suggestions please? Apologies for the double querie Edited 2022-04-10 20:00 by nambuat |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1621 |

Got 85 acres here and at the start of last year got a call from my neighbour suggesting if he replaced my back fence could he put his sheep on to pay for it. I bought a 12' gate which they installed and in Jan this year we were all squared up so when he rang me to let me know I said mate if you want to do the front fence then the sheep can stay on as it does cut down the fire risk etc. He came around and did a measure up and we had a good chat where a PA gate is getting put in and i will mark out where the phone line is buried using my metal detector. Got a letter this week saying 115 weeks minus the weeks since our last agreement finished at the start of June the fence will be done. So with that front fence around 1.6K of free fencing and saved a heart attack where looking at the price of the fencing gear. |

||||

| Godoh Guru Joined: 26/09/2020 Location: AustraliaPosts: 605 |

Bryan, it may be worth having the arrangement in writing. There have been cases where someone has gone into a deal like that and found that after 7 years, the person who was doing them a favour by running their animals on the land has claimed adverse possesion of the land and taken it off them. Many years ago a former Mayor of a Tasmanian shire did just that. Some people bought the land next to him, they told him that it would be a few years until they moved down. He said "do you mind if I run some stock on the land to keep the grass down", next time they saw him he said 'do you mind if I put a dam in to water the stock". There they were thinking he was being helpful and generous. But on moving down to the land over 7 years afterwards , he told them that they were trespassing on his land and forced them off. He claimed adverse possession, knowing all the time what he was doing. Not saying your neighbour would do that but be cautious. Pete |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1621 |

not a problem at all here mate we bought the farm back in '03 and our neighbour is about a 5th generation local and they own 7/8's of local farming area as there GGG grandad was Sa's first surveyor who close this area out of the whole state. To answer you question about in writing the arrangement is done on paper and I ring to confirm then after completion of the contract more paperwork so everything is above board. By the way no chance of using a ride on mower here as too many submerged rocks would take the blades out after 5 minutes |

||||

| Clockmanfr Guru Joined: 23/10/2015 Location: FrancePosts: 437 |

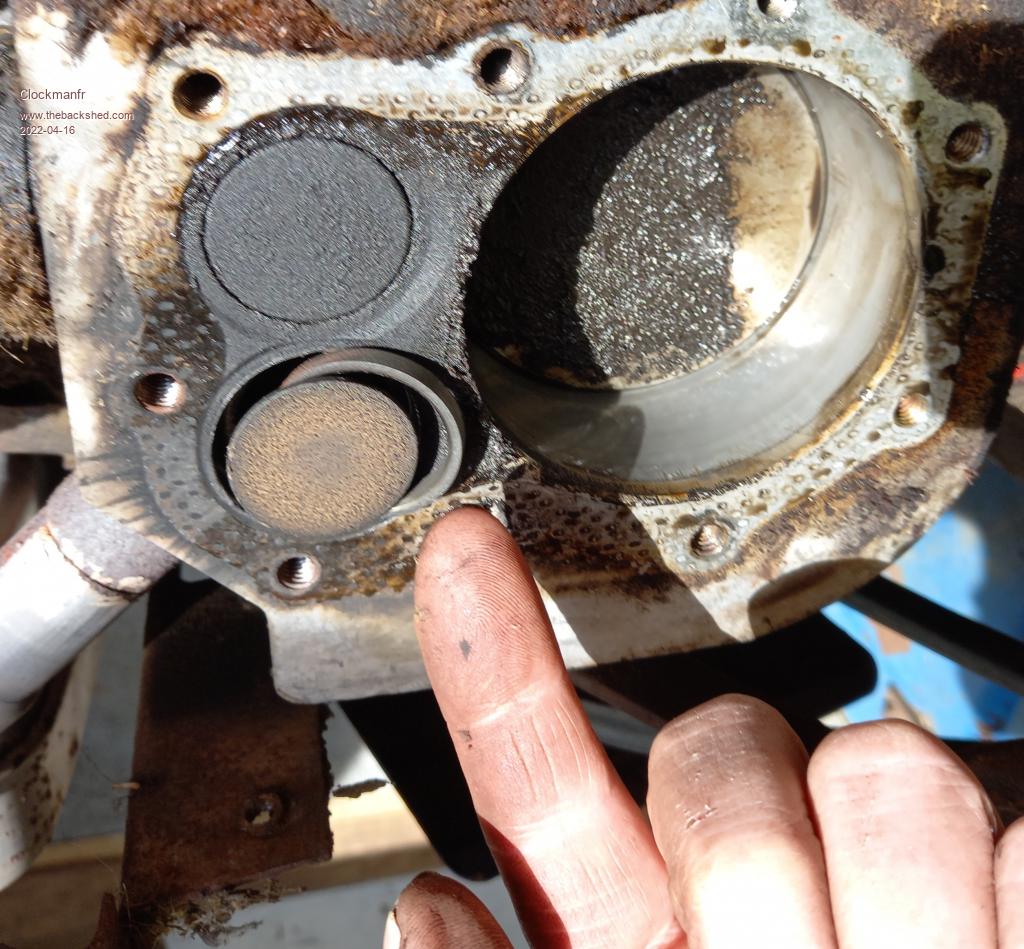

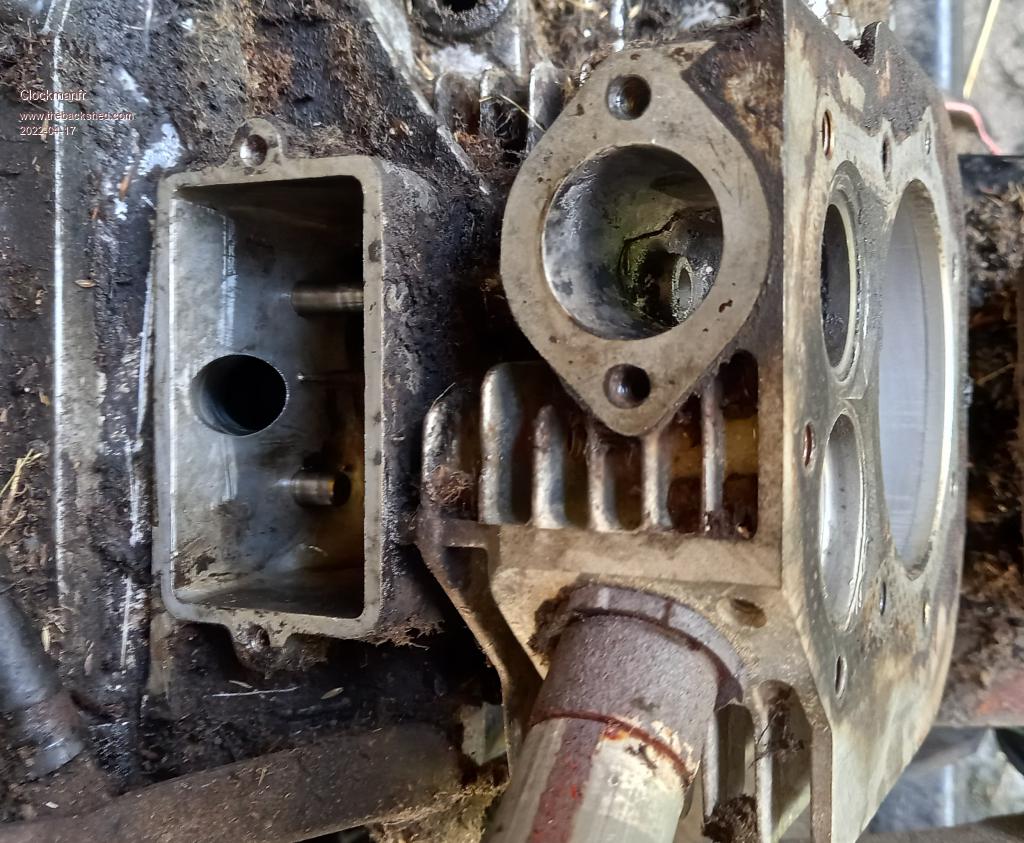

Here is my 46 year old Roper 16t, made in the USA, probably see me out. haha!. Lots and lots of solid thick steel, great but very heavy machine.  Oh bloody hell! I thought the front cylinder was losing compression.  Everything is possible, just give me time. 3 HughP's 3.7m Wind T's (14 years). 5kW PV on 3 Trackers, (10 yrs). 21kW PV AC coupled SH GTI's. OzInverter created Grid. 1300ah 48v. |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1251 |

Yep that will sure reduce the compression alright! Never seen that happen before, how do you replace or re affix the valve seat or is it time for a replacement head ? It otherwise looks in pretty good nick for 46 years old. If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| phil99 Guru Joined: 11/02/2018 Location: AustraliaPosts: 2957 |

Another head won't fix it, its a side valve engine. That's the barrel. Could be expensive to fix. The usual method is to weld up the port so it can be re-machined then shrink a new seat in liquid nitrogen and slap it in before it expands. The soot marks show the head gasket was leaking prior to the seat failing. Perhaps the engine was seriously overheated at some point in its life. |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1251 |

Thanks Phil, when I first looked at the engine I did think old engine side-valve type (Ford Prefect came to mind), then I focused on the valve seats and of course all the engines I have actually worked on over ~ 40+ years have all been overhead valves so my brain inverted it and I asked the dumb question....... Great analysis of the leaking head gasket, I registered all the soot but didnt register the leakage outwards by the exhaust valve - I think you can read engines the way I can usually read a circuit board lol. Edited 2022-04-17 01:03 by wiseguy If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| Clockmanfr Guru Joined: 23/10/2015 Location: FrancePosts: 437 |

Dropped valve seats do occur on these old Briggs & Stratton side valve engines. Here is a vid, there are more like this to be found on the Utub..... https://www.youtube.com/watch?v=7wsBj7qwlPMhttps://www.youtube.com/watch?v=7wsBj7qwlPM I dont fully recomend this peening process and it should be done more neatly. But you get the picture. Note, practice on a small bit of the cylinder ally to see how the metal behaves, it should be workable and mould nicely as most modern engines the ally is brittle, so carefull. Ordered a new valve, a new valve guide and a new seat. The intake is okay but needs the valve stem grinding down a very small bit. ie to give valve follower and valve stem expansion clearance, Its the exuhast that has fallen out, probably 46 years of getting just to hot. However being a side valve there is plenty of ally to peen around and over the new valve seat to keep the valve seat in position. It seems that even a few swaging/peening points do work well. The valve seat is hard and very brittle so dont hit that. Getting every thing to act true and the valve to seal correctly when working will take some precise work, especially with the Valve guide which is well worn, so the new guide will require trueing up on its intallation and reaming out. Nice thing with this side valve is that it can all be done as is, no need to take the engine down.  Edited 2022-04-17 18:50 by Clockmanfr Everything is possible, just give me time. 3 HughP's 3.7m Wind T's (14 years). 5kW PV on 3 Trackers, (10 yrs). 21kW PV AC coupled SH GTI's. OzInverter created Grid. 1300ah 48v. |

||||

| johnmc Senior Member Joined: 21/01/2011 Location: AustraliaPosts: 282 |

Good day All When we repaired valve seat insert faults, we machined the valve seat where the insert fitted. then fitted oversized valve seats. Penning around the old valve never works because the heat transfer to the cylinder block is very poor and the seat will again drop out. It is not that expensive to get it repaired by a engine repair shop. Or if you have access a lathe make your own cast iron valve seat, fly cutter to cut the seat, a guide to fit the oversize seat insert and some liquid nitrogen to freeze the insert, or heat the cylinder block and freeze the insert in the house freezer. The seat guide is to make sure that the seat is fitted with one hammer blow, before there is time, for the heat of the block to transfers the insert. cheers john johnmc |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |