|

|

Forum Index : Microcontroller and PC projects : PIC Moisture Sensitivity

| Author | Message | ||||

| Poppy Guru Joined: 25/07/2019 Location: GermanyPosts: 486 |

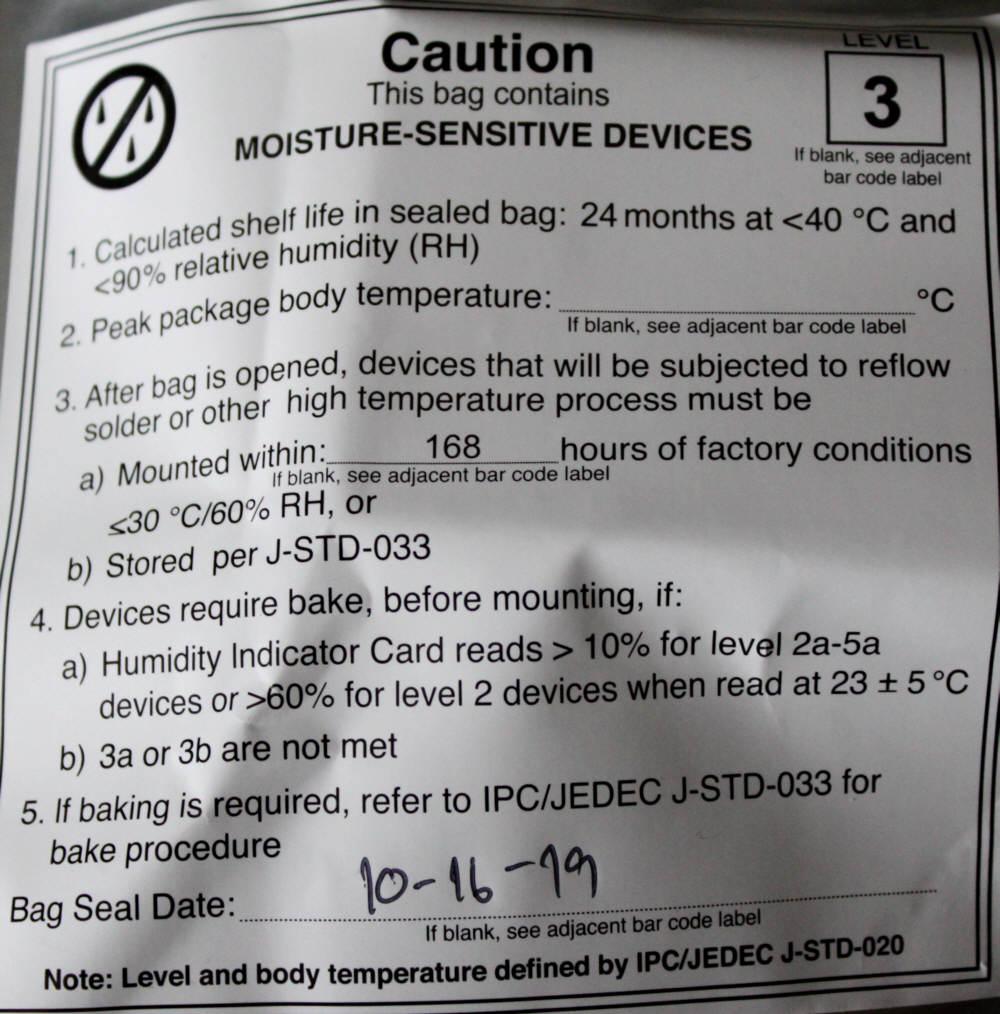

Hi Folks,  I just ordered and received some IC´s from microchipdirect.com, all of them were just static sensitively packed except the CMM-CPU´s (PIC32MX) they were specially packed for moisture sensitivity, with a declaration concerning further handling and storing (J-STD-033 ->Picture). Do these guidelines, especially including baking before mounting and mounting within 168 hours after opening the bag, only depend on applying reflow-soldering or will the chips be harmed generally by simply storing or manually soldering outside this time frame? ... meaning, if I just open the bag and keep them stored until I solder them with my iron or hot air ... when ever, right now or a year later?!?!? I cannot imagine what difference in handling this should make to already mounted IC´s on PCB´s just lying around on my desk and being still working, or is this just necessary for "highliest-professional NASA-purposes"?     Edited 2019-10-23 20:55 by Poppy  Andre ... such a GURU? Andre ... such a GURU? | ||||

| cosmic frog Guru Joined: 09/02/2012 Location: United KingdomPosts: 307 |

If you are just going to solder with a normal soldering iron don't worry. But if you are using a reflow station and the chip has taken on moisture it has the risk of "popcorning". Dave. |

||||

| ryanm Senior Member Joined: 25/09/2015 Location: AustraliaPosts: 203 |

Moisture sensitivity is all about reflow ovens as far as I know. If the bulk substrate of the package (whatever kind of part it is) is porous it can absorb atmospheric moisture into it. If you then quickly heat the whole part it can "popcorn." Same as throwing river rocks into a campfire. Never seen it happen in person, I've always just resealed the bags with a bit of duct tape out of precaution. I use MSL above 3 parts so you should be fine. Thermal stress on the bulk of the part will be way less hand soldering anyway. |

||||

| SimpleSafeName Guru Joined: 28/07/2019 Location: United StatesPosts: 351 |

Just put them in a toaster oven (aka your reflow oven) on low for a few days prior to soldering. I have to dry my 3D filament for the same reason. |

||||

| Poppy Guru Joined: 25/07/2019 Location: GermanyPosts: 486 |

"Popcorning" as what I already read about it myself and I guess this issue depends on completely heating the IC. So if I thankfully understand you all correctly this does not matter for just heating up the pins during soldering with a normal iron or a heat gun, so doing no reflow at all myself!?!? And what about the time frame for soldering? Edited 2019-10-23 23:05 by Poppy  Andre ... such a GURU? Andre ... such a GURU? | ||||

| cosmic frog Guru Joined: 09/02/2012 Location: United KingdomPosts: 307 |

Take as long as you want if just soldering the pins. |

||||

| Poppy Guru Joined: 25/07/2019 Location: GermanyPosts: 486 |

Thanks!   Andre ... such a GURU? Andre ... such a GURU? | ||||

| CaptainBoing Guru Joined: 07/09/2016 Location: United KingdomPosts: 2171 |

my kid works in this industry with GE and they have hell an' all problem with SMD caps popping in re-flow and changing over time |

||||

| Poppy Guru Joined: 25/07/2019 Location: GermanyPosts: 486 |

... and on worst case scenarios they start a party: https://www.youtube.com/watch?v=YfdLh0MHqKw   Andre ... such a GURU? Andre ... such a GURU? | ||||

| CaptainBoing Guru Joined: 07/09/2016 Location: United KingdomPosts: 2171 |

dammit. you do know it's not possible to "un-see" things.. i am never going to get that out of my head now  |

||||

| Poppy Guru Joined: 25/07/2019 Location: GermanyPosts: 486 |

I know, I know ... I am suffering with You  This so damned ... great to watch    Damned Popcorn   Andre ... such a GURU? Andre ... such a GURU? | ||||

| Paul_L Guru Joined: 03/03/2016 Location: United StatesPosts: 769 |

My generation had Spike Jones. Then came the frug, disco, and Tiny Tim. Now we have pop corn. What else is new? |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |