| Author |

Message |

matherp

Guru

Joined: 11/12/2012

Location: United KingdomPosts: 8592 |

| Posted: 12:04am 10 Dec 2014 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

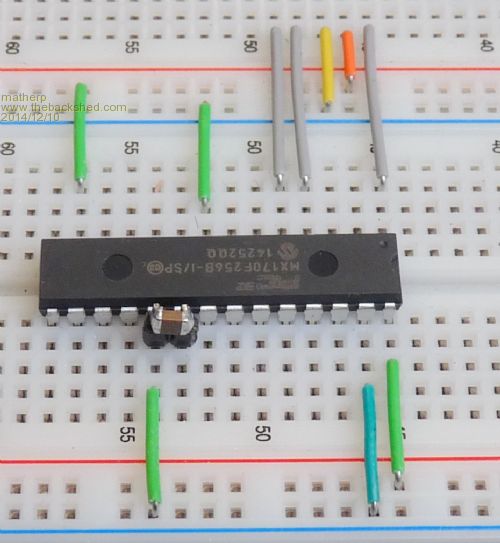

Silly little trick but perhaps useful.

1206 SMD parts solder perfectly to 2 pin headers which makes them ideal to use on breadboards rather than getting the poor connections which thin wires can give.

In particular this is useful for the Vcap capacitor for the PIC32. High value multilayer ceramic capacitors are the best solution for Vcap and as can be seen in the picture, soldering one to a header makes it trivial to use. I use a small crocodile clip to hold the capacitor in place while I solder the first side.

|

| |

MOBI

Guru

Joined: 02/12/2012

Location: AustraliaPosts: 819 |

| Posted: 01:17am 10 Dec 2014 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

That's a good idea.

I do something similar with a couple of short pins soldered to the cap but yours has the added advantage of mechanical strength of the header pin moulding. My caps are a bit bigger than yours and I have to put them in holes diagonally to fit.

David M.

|

| |

paceman

Guru

Joined: 07/10/2011

Location: AustraliaPosts: 1328 |

| Posted: 01:20am 10 Dec 2014 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

That's nice and neat Peter. They solder neatly across Veroboard track too, as do a lot of SMD parts. I've seen someone on TBS who soldered them direct to the chip pins too, close to the plastic!

Greg

|

| |

G8JCF

Guru

Joined: 15/05/2014

Location: United KingdomPosts: 676 |

| Posted: 01:37am 10 Dec 2014 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

If U buy uMite chips from Phil at Micromite.org, he solders a tiny cap across 19 and 20 for you.

The use of pin header is good, I use blue tack to hold the smd cap to a toothpick, the pin header in a wee jeweller's vice, leaving the other hand free for the soldering iron.

Peter

The only Konstant is Change |

| |

Grogster

Admin Group

Joined: 31/12/2012

Location: New ZealandPosts: 9066 |

| Posted: 01:51am 10 Dec 2014 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Ahhhhhhh - 1206. My SMD size of choice.

1210 is a monster - you might as well use standard thru-hole parts. ...although some parts like high value tantalum's, you can only get in 1210, so there is a physical threshhold...

0805 I find too fiddly, despite it supposedly being the default standard for SMD for most people.

0806 and 0804 I don't even breathe on.

Smoke makes things work. When the smoke gets out, it stops! |

| |

robert.rozee

Guru

Joined: 31/12/2012

Location: New ZealandPosts: 2290 |

| Posted: 03:44am 10 Dec 2014 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

(imperial) 0603 is a walk in the park, while 0402 requires a little extra care

the trick is:

(1) a 4" loupe,

(2) lots and lots of light,

(3) a qualitypair of pointy stainless steel tweezers,

(4) a reputable hot soldering iron, weller WTCPT/TC201 and PTH7 bit is my choice,

(5) any reels of lead-free solder carefully placed in the trash can outside.

leaded solder and a jar of flux paste are essential consumables, along with solder wick.

can't emphasize enough the importance of having the right tools. the old weller magnastat irons are magic. i must convert mine over some time to have an SSR switch the element and an XLR plug on the lead to the handset.

cheers,

rob :-) |

| |