|

|

Forum Index : Microcontroller and PC projects : Touch display escutcheon

| Author | Message | ||||

| OA47 Guru Joined: 11/04/2012 Location: AustraliaPosts: 1036 |

I have been frustrated by the lack of finish with my projects using the touch displays as saws and files are my only weapons in the shed. I have been wondering if there are any shedders out there that have the facilities and the inclination to manufacture some neat escutcheons that would surround the perimeter of the screen to hide the cut out edges of a case. I would imagine that the surround would have angled edges toward the display to allow access to the extremities of the touch surface but still hide the areas out side the screen. The same mounting holes could be utilized to attach the surround. Any feedback would be appreciated. Graeme |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9875 |

I hear you.

Escutcheon's/Bezels for LCD's seem remarkably hard to find, despite the LCD's themselves being very easy to find. It would be easy-enough to design something in QCAD or similar, to be laser-cut from perspex, and would look the part in every way, but as to if anyone wants to do that...... Bevelled inside edges would be nice - not sure if the standard laser cutters can do that though, as they might only be vertical-cut machines. If anyone has done something like that, PLEASE do post here - we LCD users would probably all love to hear from you. Smoke makes things work. When the smoke gets out, it stops! |

||||

| Benzol Regular Member Joined: 07/01/2015 Location: AustraliaPosts: 64 |

I took my piece of perspex to the local sign manufacturers who made the appropriate cutout with their CMC routers. It did cost me $20 but as I had taken the original piece of perspex out of their scrap bin the week before I figured I shouldn't complain. |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2979 |

Hi Graeme (x2), All, I have yet to try this but I have thought about those cheap, thin glass protectors that are available for mobile phones.. mask off the area of the screen size you want and paint the underside of the glass with black paint then remove your mask and attach this to the TFT screen.. The only catch is the glass may not work with the resistive touch screens.. As I said I haven't tried it. Kind Regards, Mick Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

| Phil23 Guru Joined: 27/03/2016 Location: AustraliaPosts: 1667 |

Maybe someone that's into 3D printing could help out. Some interesting examples here. Maybe if someone can come up with some designs they could be printed commercially. http://3dprint-au.com/ Phil. |

||||

| matherp Guru Joined: 11/12/2012 Location: United KingdomPosts: 10953 |

It is easy enough to do, see this thread for the bezel I printed for a 4.3" SSD1963 display (ignore the colour  ). ).

The issues are things like: the huge range of displays does the bezel mount onto a purchased box or do we need a printed box as well if a printed box, where do the cables come out and how many etc. |

||||

| WhiteWizzard Guru Joined: 05/04/2013 Location: United KingdomPosts: 2960 |

One approach I have used with a very neat finish is thin plastic sheeting cut with a computer controlled vinyl cutter. Search for 0.5mm HIPS - you can pick up an A4 sheet for not much money at all (and in various colours). I used a Silhouette Portrait Vinyl Cutter with the HIPS after designing my front panels in Corel Draw. The cutter will cut through much of the thickness, and only slight 'man-handling' is required to get a clean break. This method allows for the many different TFT sizes that are available (as Peter highlighted). By the way, the laser cutter approach only resulted in vertical cuts in perspex. It was ok, but I think I would always prefer the 'bevelled' CNC approach (again using HIPS, but with a 2mm - 3mm thickness). WW |

||||

| WhiteWizzard Guru Joined: 05/04/2013 Location: United KingdomPosts: 2960 |

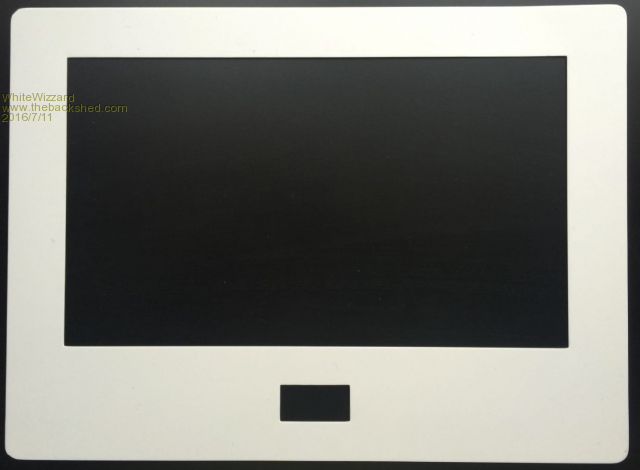

A picture paints a 1000 words; so here's 2000 words

Note that this is 0.5mm HIPS so is flexible (which is why the bottom picture looks like the panel is 'bendy') WW |

||||

| Phil23 Guru Joined: 27/03/2016 Location: AustraliaPosts: 1667 |

I think for a starting point, replacement lids only would be the way to go. The mob I mentioned above structures their pricing on bounding box cc's. 23c per cc. So using the Super Clock as an example, it maximum cost would be 0.23x7x14=$20.93. That's assuming it's 1cm thick which it's not, but minimum price is $20.00 anyway. If it was a complete box 5cm high it becomes about $105. Phil. |

||||

| OA47 Guru Joined: 11/04/2012 Location: AustraliaPosts: 1036 |

This is what I had in mind:

There are available bezels for the 4D Systems 4 inch displays:

I am specifically interested in bezels for the 2.4/2.8 inch Serial displays. |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

If you have a router then it is not too difficult to make. Buy some acrylic, leave the protective film on it an tape/glue it in the center of a a piece of scrap wood. The staple/glue some strips of wood to act as a guide on all four side. Then take a 45 degree router bit and route out the center. Depending on the thickness do it in 2-5 passes. Clean it up with some fine grit sandpaper and if you want a glossy surface run over very quickly and not too close with a torch. We did this many times in the makerspace for screen bevels. Another way is to just cut it straight, with a lasercuttor or jigsaw. Make it fit tight, if not hetn fill it with some dissolved acrylic. Use an phone or ipad screen protector and put it on the whole surface. Microblocks. Build with logic. |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |