|

|

Forum Index : Microcontroller and PC projects : Great tutorial for Android Apps + Bluetoo

| Author | Message | ||||

| CaptainBoing Guru Joined: 07/09/2016 Location: United KingdomPosts: 2171 |

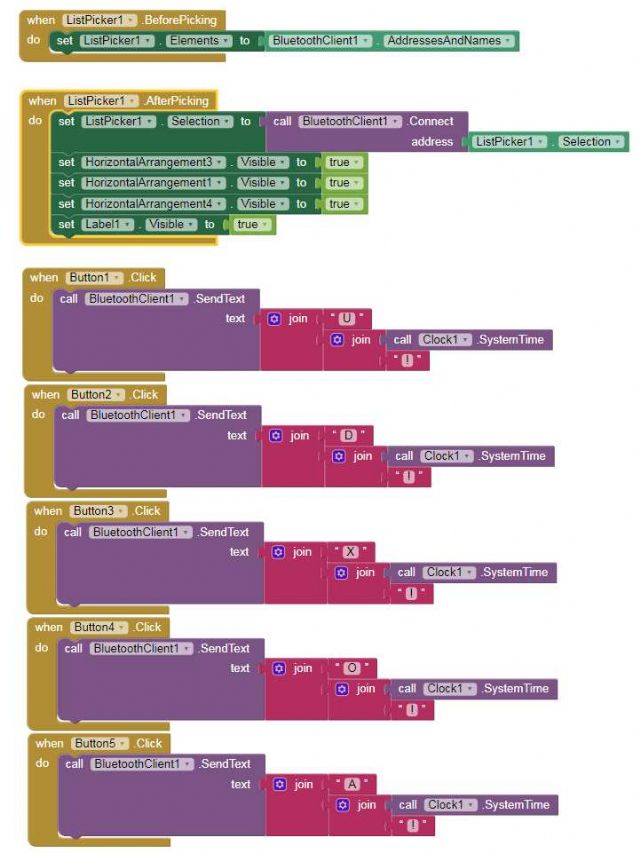

Uses MIT's App Inventor. Garage door App on my phone -> Bluetooth connected MicroMite finished is 4 hours. |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

Cool.... was there supposed to be a link or attachment? Android device talking to MM device really is easy/fun. |

||||

| CaptainBoing Guru Joined: 07/09/2016 Location: United KingdomPosts: 2171 |

oops! - well spotted https://m.youtube.com/watch?v=evVRCL9-TWs   Then processed the strings on the uM. I piggy-backed the uM on the existing controller (don't want to lose or interfere with existing functionality - it must always work the same way it used to). Will post the uM code soon. I have a look up for daytime in the uk and it will put the external light (over the door) on when the door is opened automatically if it is outside daylight hours for the date. It has no RTC though! I send the unixtime from the android device each time and it will set its clock from that - just in time processing  The light functionality on the app is for the internal light - on or automatic (on PIR sensors) I never seem to have the plipper with me when I want it but I always have my phone. |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

This is my Android tablet, making parts for one of the big car producers: https://www.dropbox.com/s/69r5jvs4o7jujlm/20140625_152851.mp4?dl=0 |

||||

| CaptainBoing Guru Joined: 07/09/2016 Location: United KingdomPosts: 2171 |

nice! you did the software? Native programmer? |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

Yeah, the software for both the Android UI and the real-time (micro-controller) that drives the 6 CNC axes (electric and hydraulic closed-loop servo motors/valves). I also installed the hardware, wired the machine and built the control pedestal. The tablet enclosure is CNC milled from a solid chunk of aluminium and has an industrial electrical connector for power. The user has no access to the fragile micro-USB ports. The tablet software is 100% B4A (Basic 4 Android). I am currently doing two more similar machines but much bigger (for 76mm and 100mm diameter tube), plus a simpler machine which is my test-bed for the MM E100. My intention is to use MM to coordinate the real-time slave processors, in the future. One step at a time, though. The Android UI has been well received; if it ever fails or gets damaged, grab another Android device - even a phone - and log-on to the machine's Gmail account to find the APK in the inbox. Simply install the app and your machine is up and running in minutes. Last week, I was called out to help another company because their machine was down. It turns out that their Siemens touchscreen has died after only two years. A replacement from R.S. is £3,499 + VAT. The customer is not prepared to pay this, he plans to rip out the entire Siemens system and replace it with my product. :-) |

||||

| CaptainBoing Guru Joined: 07/09/2016 Location: United KingdomPosts: 2171 |

I am in the shadow of greatness! Nice work  |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

Thanks but no greatness when it's just a matter of repackaging the same thing, over and over, for the past 30 years  |

||||

| CaptainBoing Guru Joined: 07/09/2016 Location: United KingdomPosts: 2171 |

shhhhh that's how we make our money right?  |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |