|

|

Forum Index : Windmills : Oz-Ax-Flux 3 Kw +

| Author | Message | ||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

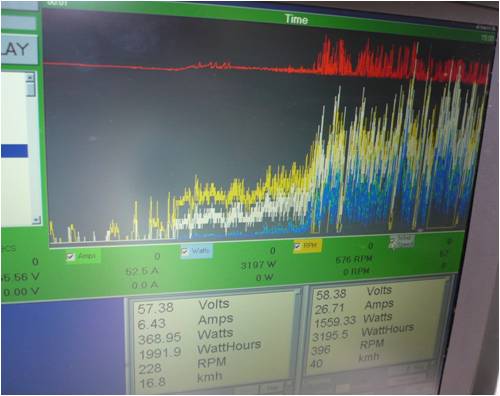

Well ,another day blowin a gale , I swapped the blades from the F&P onto the Ax the other day and put the old ABS blades on the F&P Dual . With the blade dia now down to 3.1m I figured it would not be able to get to the highs it had a couple of weeks back before the blade let go . Wrong again with a blast of wind coming through at 57klm it punched through 3 Kw ( 3197w @ 576 Rpm ) shown below the recording on the piclog. I have had it down quite a few times today to keep reseting the furling moment and have been keeping a eye on how hot it is running and after quite a long period of high output , I was still able to hold my hand on the housing for as long as I wanted , and no smells of heated resin coming from inside , which is a good sign

The furling now is starting in 25 to 30 klm and is fully furled at 40 , but even in the fully furled position it is punching out arround 2Kw .. But the best thing is when the wind dies down to nothing and the Cap/doubler/quaddrupler takes over and keeps the power flowing with out stalling the blades , No complicated star /delta switching or mppt tracker.. I have been in the design process recently of a bigger Ax Flux on a 400mm stator dia , but after the last couple of weeks and thinking if there was a bigger one up there in these winds it would have to be permantly shut down , there is no where for the power to go as the PVE 1200 is at its max coping with this one and the F&P dual , but in this wind I can't stop the F&P even with the 2.8m "Howling Banchee" Abs blades where its a flick of a switch and the Ax stops PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Interesting to see that the best AxFx design (in combination with "Cap/doubler/quaddrupler") was made here, in Australia where F&P is the king. So good, that those on Fieldlines They could not believe. Congratulations to all people involved! Vasi Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Vasi , Thanks for your kind comments , officially this design , which is brain child of Gordon who originated the design basics and the electricial wiring specs and also some where there I am sure Oztules also had a helping hand , the process of engineering the design was quite a handfull but in the end well worth the effort , overall the two mills that are up and flying here , mine and Gordons do have some engineering and electricial differences and both are performing extremely well . We have decided to make claim to this design and call it our own , as there does not seem to be any thing like it out there in the wind generator world , and call it "The Oz-Ax-Fx" The part that is specific to mine is the PVC blades , which Glenn played a major part in getting them into production , can extract the power from the wind quietly and efficiently which is more than obvious in the output figures from my mill .... PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

The Oz-Ax-Fx, I like that  The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

(THERE IS NO WHERE FOR THE POWER TO GO)

Phill such a nasty problem you have there? Wish I could say that. Your having to much fun. Jim |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi Phill, The 3.1kW from a 3.1m rotor is getting pretty extreme. How is the stator handling the abuse? There were worries that the enclosed design would cook and burn up. I have not been able to check mine for signs of heat yet. My coils are hollow, so there is a larger surface area for cooling. The windmill must still be above 90% efficient at 3kW, or else I would expect smoking coils. Probably need to see how fast the stator rises in temp with say a fixed current through the coils at say 10A. I expect that the windage factor at the 400-500rpm would cool the system quite effectively. Gordon. become more energy aware |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

It is this kind of behaviour (cut the blades down... expecting less power) that confounds the engineers when they first dabble in wind. There are so many things that go into a balanced system, all fighting for their particular niche, it is easy to lose sight of what we are doing half the time... and is exactly why it is useless to optimize any one part of the system, without keeping an eye out for unintended consequences. I think it is also an indication that these blades... whilst not optimized (compared to a blade calculator), without taper, and without twist, give a great all round performance. They won't be super fast, but seem to run over a wide TSR, with plenty of torque...can't ask for more than that. With your bigger blades, you may have room for more caps...

Good stuff. .........oztules Village idiot...or... just another hack out of his depth |

||||

| HeadsUp Regular Member Joined: 06/12/2009 Location: AustraliaPosts: 43 |

hi mate . can you tell me what you are using for data capture ? is that a USB connected oscilloscope on your computer ? and also , is there more detail somewhere on the AX FX construction you used ? .. and the circuit you are using for the cap doubler ? trying to find ways to improve bottom end start up in the low wind range and lift average power production here with AXFX. .. i also have a 3 phase 7.5 kW 4 pole ACIM which i want to use on a VAWT and some 300 A IGBT modules to build into an inverter too :) |

||||

| Perry Senior Member Joined: 19/11/2009 Location: Posts: 190 |

Aint that the truth! Perry |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Perry , Heads The data logging is done by the Picloger that Glenn origionaly designed , this one I have is a dual piclog and was modified to suit 48v and tricked up a bit by Gordon as is the cap/doubler setup , both these are in the main page info somewhere . There is further detail on how I built the Oz Ax Fx in a post called Homegrown Ax Fx . It was designed with lower resistance to use the cap/doubler to get the low wind power then at 200rpm its raw power with max efficiency and very little stator heating. Yea , Perry these blades can really deliver the power , I have always said " no power in = no power out " . I stuffed arround for years wasting my time trying to build a good blade , I thought my ABS pipe blades were good untill I tried these . Would't waste my time doing all that again .. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |