| |

Page 2 of 2 Page 2 of 2 |

| Author |

Message |

shawn

Senior Member

Joined: 30/03/2010

Location: New ZealandPosts: 210 |

| Posted: 08:28am 03 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Geat tracker yes have heaps of room out in padock thankyou again pete sometimes I just cannot see the wood for all the trees are in the road.

so now to start at the bigining again without getting to tecnical and not running low volts far which voltage gives best performance in average winds with f&p I know this is A hard question without all the wind statistics but with all the experts here I would be happy to go with winning vote.

My power use is very low would beat most at this. |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 11:14am 03 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Im not the eepert on this but my guess for 24v would be Delta 2x7c but this might be dependant on what stator you have ..60s, 80s, 100s???

Karl and others are more up with this than me.

As for the white colourbond windwall around the solar tracker i think it would be to tricky to get the angles right to suit throughout the year operation and to put the money into an extra panel would return more power over the 12 months.

Pete.

Sometimes it just works |

| |

KarlJ

Guru

Joined: 19/05/2008

Location: AustraliaPosts: 1178 |

| Posted: 03:22pm 03 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

some quartz rocks may do the trick pete.

go for 48V of at all possible as cables smaller and everything gets hot with Amps, much tougher to fry things with lower current, all your Bridge recs need handle only half (or 1/4 if your talking 12V)the current they do at 24V

you got an 80 and a 100S thus you're good for either 24V or 48V with simple rewires

and the 48V means the option of adding to a GTI.

imagine 8hrs of 800W what do you do with it?

must have useful work to do with it or it all becomes an expensive hobby.

Luck favours the well prepared |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 05:12pm 03 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

As for reflected light back onto panels on a tracker, I ask you to play with a mirror. just keep the sun on a surface simulating the panels then reflect what you can from a miror back onto your panel area and take notice of the angle of the mirror and light.

I think the refector would need to be too far away considering the tilt on the panels for it to be practical.

Pete.

Sometimes it just works |

| |

AllanS

Regular Member

Joined: 05/06/2006

Location: Posts: 67 |

| Posted: 09:33pm 03 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Pete,

Seeing how sturdy your tracker looked, my idea was to attach the white reflector onto to perimeter of the panels so the whole contraption is bowl-shaped and always facing the sun. Diffuse reflection can pack a punch, and white colorbond would be easier to work with than mirrors. |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 03:30am 04 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Allan.

Ok i get what you mean but you need to remember the tilt is adjusted a little for summer and winter and if it was me i would not have any bigger wind sail than needed as there is already a fair size sail in the panels alone.

The other thing is the sun in early morning and late afternoon being blocked if not careful.

I do agree there is a lot to be had from reflected light but its not as easy as one might think due to the sun is only directly over head at midday and in winter it is on a much different angle to the panels and then over heating on hot sunny days is a problem to.

Me think keep it as simple and as slim as possiable and put any extra dollars into more panels and a second tracker with time.

Here is a couple of more pics.

Pete.

Sometimes it just works |

| |

shawn

Senior Member

Joined: 30/03/2010

Location: New ZealandPosts: 210 |

| Posted: 05:34am 07 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

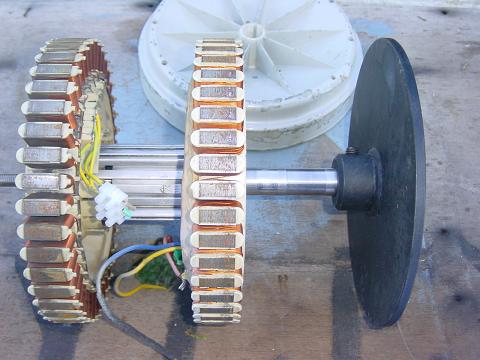

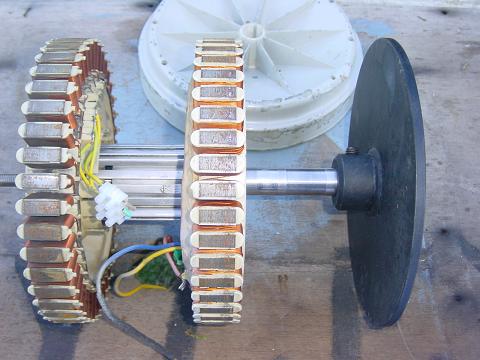

Just some pictures to share first was sad ending cause was bad enginering on my part 4m blades hit tower in high winds

Next windmill direct drive this time |

| |

GWatPE

Senior Member

Joined: 01/09/2006

Location: AustraliaPosts: 2127 |

| Posted: 08:04am 07 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

They are some fairly substantial chunks of timber to hit the tower.

Is the wood from a "rubber tree". :)

Gordon.

become more energy aware |

| |

shawn

Senior Member

Joined: 30/03/2010

Location: New ZealandPosts: 210 |

| Posted: 08:26am 07 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Imported american oregon lovely wood close grain.

wife recons she was tripping over my bottom lip for A week.  |

| |

GWatPE

Senior Member

Joined: 01/09/2006

Location: AustraliaPosts: 2127 |

| Posted: 02:13pm 07 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

I am flying a set of 3m dia Oregon blades that I made, on my mill. A picture is on F&P@PE thread I think. These are working as well as Lakota blades, when compared on the same W/m^2 rotor area basis. You can make blades as good as the commercial units.

The dual rotor F&P will be a better match for the large bladeset.

Gordon.

PS: that is a decent size tail on that mill.

become more energy aware |

| |

SSW_squall

Senior Member

Joined: 20/03/2010

Location: AustraliaPosts: 111 |

| Posted: 03:08pm 07 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Bother!! Condolances are definitely in order...

Never mind lips, my shoes would be lead weights, if that happened to me!

On the positive side, any bird (endargered or otherwise) silly enough to venture too close won't stand a chance against those knife points... hehe

AB

Einstein: Everything should be made as simple as possible, but not one bit simpler |

| |

shawn

Senior Member

Joined: 30/03/2010

Location: New ZealandPosts: 210 |

| Posted: 09:47am 08 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Your imput is appreciated, learning all this yourself takes ages and kills mills! I found out the hard way.

should the next blades be 2.8 or 3m or ??

can also laminate extra wood on the thick end for better startup.

My last set were 4m tsr 8 pigot design

Also am going to buy caps to use before rectifiers this is not something I will do myself but would like to know how many I will need to buy and size.

Will take photo of making new blades as I used A router. |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 09:55am 08 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Shawn,

Give Gordon a PM and he might run your set up through some software he has to calculate the best cap setup for your mill.

Pete.

Sometimes it just works |

| |

MacGyver

Guru

Joined: 12/05/2009

Location: United StatesPosts: 1329 |

| Posted: 01:34am 09 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Crew

I just thought I'd throw this everyone's way. I'm working on a true ax-fx windmill, but I'm going to throw in a little twist. I'm going to make it a "down-wind" machine and place a dorsal fin atop the housing. A fin will also discourage "precession" caused by the angular momentum of the whirring blades acting against the tower-mount bearing.

I'm also going to limit the amount of circular travel so I don't have to worry about slip rings. There will be no "yaw" gear and also no over-speed protection.

Keep in mind that the stuff I construct is very tiny by comparison to those mills seen elsewhere on this forum and others. I'm only after about 500 watts total output. I like to design and build stuff, so if it works at all, I'm usually happy.

Another thing, since Shawn's mill unfortunately had blade contact with the tower; a down-wind machine coupled with the fact that I use solid aluminum flat stock for blades, will allow my blades to flex in higher winds and the more they do, the farther away from the tower they will be, thus absolutely preventing any contact. I've had up-wind blades destroy themselves and towers in the past; I know those forces are extreme.

As I get things put together, I'll post pictures. Right now I'm saving my pennies for new inch and a half neo magnets and scouting dumpsters for something to make the body out of. I'm leaning toward cannibalizing an old industrial floor fan housing and remanufacturing the insides to hold a 5/16" steel shaft set in sealed ball bearings at each end.

More as it happens.

. . . . . Mac

Nothing difficult is ever easy!

Perhaps better stated in the words of Morgan Freeman,

"Where there is no struggle, there is no progress!"

Copeville, Texas |

| |

shawn

Senior Member

Joined: 30/03/2010

Location: New ZealandPosts: 210 |

| Posted: 09:51am 09 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Pete what is a pm?? still working out all the lingo.

Sounds great Mac will watch with interest. |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 10:19am 09 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Shawn,

A PM is a personal message you send to someone on the forum.

There is a PM key at the bottom of every post direct to the member who posted the reply or a link up the top of the page to PM someone.

The easy way to PM someone is to find a post that person done and click on the PM button on the bottom of their post, Then you are set up to post a PM to the person in question.

If you want to test it out you can PM me and i will reply to you when i receive it.

Pete.

Sometimes it just works |

| |

KarlJ

Guru

Joined: 19/05/2008

Location: AustraliaPosts: 1178 |

| Posted: 01:25pm 09 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

cool I like the hub attachment to the f&P shaft but i must ask if doing up the retaining bolt causes it to move off centre enough to cause a balance problem, windturbines very sensitive to such things but if it works Phillm may use the idea as its really simple / cheap to do.

Luck favours the well prepared |

| |

shawn

Senior Member

Joined: 30/03/2010

Location: New ZealandPosts: 210 |

| Posted: 06:26am 10 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

When puting together you get a feel for how tight the fit is doing up retaining bolt just could not move it! at least its not a fear for me not sure if I used heavy enough plate for hub though?

Must confess used A frend to do this he works at Hamilton jetboat place / has good workshop.

Phillms enginering/mills outstrip mine I am going to use his arm thingy for adjusting furling simply brilliant.

Thanks also now know what A pm is. |

| |

KarlJ

Guru

Joined: 19/05/2008

Location: AustraliaPosts: 1178 |

| Posted: 06:58am 10 Apr 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

i dont think anyone would build an F&P without it now, really caught on

i liked it so much i bought it!

no regrets either still cracking in 1-1.5KW/day almost like clockwork and still no bloody wind!

when the windy season finally gets here when we have 40KM/hr winds for days on end, it will all be worthwhile

Karl

Luck favours the well prepared |

| |

| |

Page 2 of 2 Page 2 of 2 |