|

|

Forum Index : Windmills : Skystream 3.7 Mods!

| Author | Message | ||||

| Ozark Wind Newbie Joined: 13/01/2021 Location: United StatesPosts: 1 |

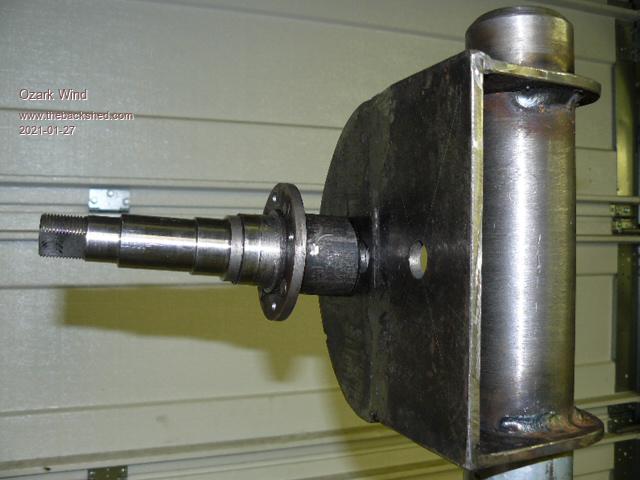

Hello to my fellow wind energy enthusiast. I was at one time a member of the Backsheds wind forum. I was seeking and asking advice from forum members on how to design and build a wind turbine generator based on an F&P stator motor. At the time I found the build very interesting, enjoyable and learned a ton of knowledge about wind energy and how to harness it. I want to thank the forum and its members for giving up their time and knowledge to see me through the build. I have uploaded some of the photos from that build. The F&P mill would average approximately 300 watts and did peak at 700 watts but only once!       Now things have changed for me and I once again seek the help and advice of the Backsheds forum and its members on a new build / mill modification. I have moved from the suburbs of Chicago Illinois U.S.A. to the Southwest corner Missouri U.S.A. The move is approximately 500 miles or 885 kilometers Southwest of Chicago. Unlike the suburbs of Chicago my new home is located in a rural area. I live on a bluff overlooking the Kings River arm of Table Rock Lake. The weather is a Hell of a lot NICER!! Warmer winters, hotter summers it's called (living The Lake Life). This area without a doubt is a much windier area then where I came from. In the process of moving I also retired and all is well. (smile) After getting settled and finishing my first project which was to build me a shop I can now move on. Shop finished plus all the other things that one does to complete a move to a new state I am now ready to start the fun projects!    Back in Illinois I helped a neighbor install a wind generator on top of a 75 foot pipe style tower. The mill was at that time sold and or manufactured by Southwest Wind Power or Southwest Wind Power Skystream 3.7. The mill was flown for approximately one year then it just stopped. I think the Skystream definitely came with its own share of problems I believe it developed a deserved poor reputation. The Skystream came equipped from the manufacture to be a grid tied. The electronics needed to accomplish this were installed in the nacelle from the manufacture, RPM/voltage, power curve, cut in RPM, the inverter, anti-islanding etc. Personally I think that housing the electronics in the nacelle of a wind turbine which a place not easily accessible is problematic. The Skystream is a downwind mill it does NOT have a mechanical brake or a tail furling over speed control. The RPM is controlled with dynamic braking ONLY. The owner's manual says the PMA has five times the torque than the blade set can produce. www.xzeres.com/?page_id=351    When the Skystream failed my neighbor was of course disappointed and so was I. My neighbor then looks over at me then says (The HELL With IT I am done with wind power) without hesitation I said (HOW MUCH $$ for the whole kit & kabolldle) LOL! I bought the mill, the tower, guy cables etc. After removing the top cover of the mill I noticed that one of the wires from one of the pickup brushes had broken this I believe was the reason the mill stopped operating. I did do some modifications and replaced the old existing pickup brush wire and also replaced the existing brush wires. I did not replace the existing pick up brushes they are still like new.    After some thought I decided to gut or remove all the electronics from the mill thinking that I will fly the Skystream with a ground based control system. The mill itself is in VERY good condition its housing is made of aluminum with large Japanese bearings, fiberglass curved blades, slot less neo magnets etc. I connected my volt meter to the PMA and spun the input shaft it does put out power. The mill is basically new or barely used.        I sometimes think that I should have kept the factory installed electronics if or when they failed then go with a ground based inverter. I haven't had much luck finding a grid tie wind inverter or wind controller. I have found a couple of SMA Windy Boy Inverters on EBAY the inverters are located in Ireland. I have made several attempts to contact the seller he responded just once saying (Either you want them or you don't there in good shape at a good price) I have researched the Windy Boy invertor long story short SMA stop making them in 2013. I would need to be able to set the inverters parameters to meet the Skystreams needs to fly properly IE. Interface cable to PC, Windy Boy Setup tool software which I was able to download, personal access code or installer password. The seller also had three Aurora Power One wind invertors for sale again I would need the installer's passcode to set parameters. The Aurora one inverters were designed to work with the Power Ones interface or the wind turbines controller IE. Ac to Dc conversion, over speed resistive braking and it's power curve adjustment etc. I would like to grid tie the Skystream. I know there is other controller's and invertors available for a gird tie mill? Any ideas, information, sourcing of components or any other help would be Awesome. Thank you from the Ozarks of Missouri U.S.A.. Edited 2021-01-27 03:20 by Ozark Wind |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

Wow that's an awesome build. What size (dimensions) and strength Neo magnets did you use? (it looks like you converted it) What motor model did you use? Did you rewire it in any way? Is it copper wound? |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |