|

|

Forum Index : Windmills : testing new shibaura(S!2) permant mag alt

| Page 1 of 2 |

|||||

| Author | Message | ||||

| aaron sa Newbie Joined: 15/08/2009 Location: AustraliaPosts: 28 |

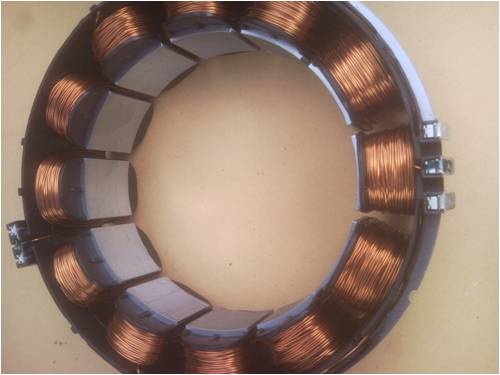

Hi all Bob and I have just been testing the new shibaura or we named s12 motor for wind mills with simular performance to fp and improvements no cogging  . they are metal housing with 12 coils in 3ph series star. they are very easy to get to all rewiring points and there are 4 coils in each star leg. the magnets rotate inside oposit to fp , they have laminates between the magnets and are very strong . they have good bearings and seals but also has a gear lever witch can make it direct drive simular to fp peformance or 6.5 to 1 ratio (perfect for vertical , i guess it is a planetary gear box inside if the metal case . it has 2 stainless input shafts / blade . 1 inside the other the gear box can lock both together in 1 to 1 or spin opposite in 6.5 to 1 guess you could have 2 counter rotating props that would be 12 to 1 ???or move the gear lever more and just the center shaft to 6.5 to 1 . The shaft is 30 mm diameter and inside is splined 15mm i wouldn’t like to mount a big prop on the 15mm shaft but the 30mm is good . . they are metal housing with 12 coils in 3ph series star. they are very easy to get to all rewiring points and there are 4 coils in each star leg. the magnets rotate inside oposit to fp , they have laminates between the magnets and are very strong . they have good bearings and seals but also has a gear lever witch can make it direct drive simular to fp peformance or 6.5 to 1 ratio (perfect for vertical , i guess it is a planetary gear box inside if the metal case . it has 2 stainless input shafts / blade . 1 inside the other the gear box can lock both together in 1 to 1 or spin opposite in 6.5 to 1 guess you could have 2 counter rotating props that would be 12 to 1 ???or move the gear lever more and just the center shaft to 6.5 to 1 . The shaft is 30 mm diameter and inside is splined 15mm i wouldn’t like to mount a big prop on the 15mm shaft but the 30mm is good .

I have done some quick testing on 1 of the coils so multiply it bye 12 with a load on 1 coil and drill on the propeller side it made 1.7 amps at 27 vac hire rpm in 1 to 1 gear = about 550 watts with a cap it made a sweet spot in middle rpm where globes / my load were brighter and then drops off at hire rpm but it made 32v at 1.9a with about 170uf cap or 729 watts for all 12. Wow seems very simular to the fp in most performance but is easer to rewire and metal construction is stronger and can be used with big slow prop in 6.5 to 1 mode or vertical with 1 at top and 1 at bottom would be 1kw vertical with out caps and 1450 w with caps peek power ,yes the caps do work thanks deninis but is harder to turn and makes more down at the lower rpm . the unusual part is they are lighter 8.5 kg and all metal casing they are stamped 2005 .bob and I scrounged a lot for fellow experimenters drop me or bob an e mail if you would like one to test then post etc aaron32gtr@yahoo.com.au. Or bevelec@tpg.com.au 12 volt testing was less with load on 1 coil volt 15.3 and amps 2.06 /no capacitor x 12 = 315w for all coils so guess for 36 v and higher it might do 1000+ w but using the 6.5 to 1 on big prop guess would work well on tsr of 3 hahah open circuit i got 60 volts at hi rpm on drill sorry no taco . scary thing is they look like could be stacked with little lathe work and shaft with bearings so 10 of them on 1 shaft with centre bearings could do 7 kw with caps or 5.5 kw . i clicked it into 6.5 to 1 mode and open circiut on 1 coil very hi rpm got 140vac

doooo |

||||

| Robb Senior Member Joined: 01/08/2007 Location: AustraliaPosts: 221 |

What product is the motor from? PS posting your email will have the spam bots laughing with glee. |

||||

| whirlybird Newbie Joined: 08/02/2006 Location: Posts: 27 |

The motors are a brand new conceptto us we have never seen this style before and they are made by the Shibura corperation in japan but as i said in the first post some are made in taiwan but that is not unusual in these times the japs are even sending work ofshore a sign of the times I have several of each in the workshop and I cant notice any dif at all it is typical of modern japanese equipment, good quality. Wont be long before we have one flying. As these are 240v synchronous motors i wonder if the may have applications in CNC machines many foot pounds of power. Bob P.S bring on the spam bots they dont like Eudora I am because I am.I am not always right but often I am. |

||||

| aaron sa Newbie Joined: 15/08/2009 Location: AustraliaPosts: 28 |

hear is add for thease if you would like to try 1 We can post out or if you are in adelaide you can see it working and pick one or two up doooo |

||||

| aaron sa Newbie Joined: 15/08/2009 Location: AustraliaPosts: 28 |

hi few more pics inside, key for scale. what options can people think of for joining a few together as it looks a lot easer to do with these,I will turn 1 into a windmill this week.

doooo |

||||

| aaron sa Newbie Joined: 15/08/2009 Location: AustraliaPosts: 28 |

Hi had a few inquaries if you e mail us give us your adress if u want a exact quote on freight pls . and reponding to bruce the gear is changes with the black lever/ two black loops on alt side / bob is taking 2 to post ofice for u now,sending 2 at 1 time is cheeper will keep u informed bruce. they swich things on splines from direct drive to about 6.5 to 1 and can lock up the biger shaft all the way over. same as outher motors the front seals are very good and tight i just modified 1 / cut little out seal same as f&p and moved front silcon seal farwad as spinner and it is no resistance now cool and no cogging mmm when u take the coil part off and then on u will need to put carbord /thin spacers in befor u tighten the locating bolts or the magnets touch the laminates easy to do

doooo |

||||

| aaron sa Newbie Joined: 15/08/2009 Location: AustraliaPosts: 28 |

wirring 1 in delta thanks paul for helping.starndard is star with 4 series coils in each leg . difrent to fp each leg is 2 coils on 1 side and series with 2 on outher side . we rewired it into parallel delta or suited for 12 v . is cool that with flick of the black lever can turn into a vawt at 6 to 1 with top bering suported or if shaft up midldl and gear lever bit over it make counter retating shafts so u could have 1 set 44 gallon drums going 1 way and top set going opsit not shore but might be 12 to 1 then ? but wouls need a top bering with qyde wires . Thir are 10 magnets 12 coils. the mag feild is super strong. between the laminates / black bit .considering deconstructing 1 to see if neo can go in their as got no idear how magnets are inside the molded case

click hear if u want to try 1 or 2 doooo |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Ok ,,, thanks Aaron. will send cheque this morning .. Do you know what these are out of ,,must have been something heavy duty for that 30mm main shaft and that whopping big bearing??. Was looking at the Sealey's yesterday ,,,reckon they still have a place down the track ,,,, Bruce Bruce Bushboy |

||||

| aaron sa Newbie Joined: 15/08/2009 Location: AustraliaPosts: 28 |

cool yes i still use a sealey / delta on 12 footer it trickles some power down in lo winds well .would be better suited to 24 plus v like that. no noise is best thing about it .but is lo power unless can get to rewire points or mppt or transformer with cut in so dosent stall . my 5 meter 2.5 to 1 on 80 sp is very good in lo and medium winds again not a big power maker up to 20 a in present config and with caps (keeps blades staleed )it stops it running away till furles but i have light winds most of the time so starts easy like that can re wires for alot more but is av power im after may do few of the s12 on it soon . i made a storm mill the outher day as well and is 1.5 m fp 80p starts easy with the lager hub aria and is out of sight fast when going should be able to do 42 amps at 12 v in storms . doooo |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Hi Bob and Aaron , Received my 2 motors today . They look good, one looks like new. First look ,just 5 minutes ago ,it dosen't seem to have that "V" shape bakalite gear shift lever --may have to take it apart to investigate. I think these will be good . quite a solid pressed steel housing ,big shaft,no cogging .. and good fixing points . the unit lends it self to a compact generator that could be weatherproofed easily. I'll take one apart and discover the working bits more throughly. Thanks Guys . Bruce Bushboy |

||||

| aaron sa Newbie Joined: 15/08/2009 Location: AustraliaPosts: 28 |

cool good to hear u need to make few spacers to space the coil from magnets i used juice bottle plastic doubled over then tighten the 4 bolts . yes lever will be just rotating housing till is in right hole a tip is to strech the spring for constant 1 to 1 , be carfull spining it and putting fingers on wires ask bob hahah . keep me informed bruce. so far is simular to fp rpm in 1 to 1 and the coils easer to rewire. 1 ph is 2 on 1 side with 2 on outher .is hi voltseries standard same as fp but re wire to p for hi amps .coils ar series starndard, say(but is ac)start +- +- +- +- out need to parelell all ++++ and alll ---- for hier amps and rpm or sp capable as well / series parralell doooo |

||||

| aaron sa Newbie Joined: 15/08/2009 Location: AustraliaPosts: 28 |

Hi had time to tinker again . hear is few pics of front and side .is easy to mount with existing mount holes enlaged and bigger bolts all the way threw yaw pole. big washers on top mount for anti pole strike, do we all lern this the hard way as beginners ? . i use a bearing washers and ruber inside for yaw so it dosent squeek in 6 months . i think it has a coating on metal but i sprayed it inside and out with white and clear for extra protection . is alot sinpler to make than fp as metal housing easy to atach and is alredy strong and cant weight to see start up with no coging . i noticed the coil voltage is slightly difrent wich may afect lo speed little in a parrallel wiring . so a jery rig rectafer may be advantage / sepert rectafacation for each coil but smaller cos less amps . im not shore if this is due to magnet alinment being critacle or fact series dosent matter as much . this 1 is paralell wired and 1 to 1 ratio . will want to try a 1 to 6.5 ratio(as it has this inside as selectable gearbox) a unrewired soon /hi volt to hi volt rectafier (because is easy way to make 3p to 1 phase /yes coud use ac but is better as 1 ph) to a bar heater and see if it can posably do over 1 kw

doooo |

||||

| aaron sa Newbie Joined: 15/08/2009 Location: AustraliaPosts: 28 |

hi is pic of yaw or pivot bering sinple and i used on my fp mills for years with out trouble it works with standerd bering with sise botom will contact pole and top has smaler washer to contact the iner part of bering and then biger washer to suport the rubber and then mill

doooo |

||||

| aaron sa Newbie Joined: 15/08/2009 Location: AustraliaPosts: 28 |

Hi finally got the s12 mill up and you guessed it no real wind hahah . it starts easy and so far dead silent wow, I have got it in parallel delta a fast wire probably good for around 25 amps . I used a prop off 1 of my f&p so it has lager root area I found best for overcoming the cogging /lo wind . so should be to easy to start on this mill. guess it was spinning around 10 kmh before but didn’t reach cut in . In back ground is my 5 m belt driven f&p 1 to 2.5 ratio works well especially in lo wind , has a hum and I made it for my low wind zone.There are Perspex root extensions on blades that help start up . want to build a vertical soon with the s12 as dident befor cos coging was to niosy for drum type on f&p. will use the s12 in 6.5 to 1 doooo |

||||

| aaron sa Newbie Joined: 15/08/2009 Location: AustraliaPosts: 28 |

doooo |

||||

| aaron sa Newbie Joined: 15/08/2009 Location: AustraliaPosts: 28 |

had little wind and the ampy rewire (parralell delta)is to lo in volts so rewiring a stater to a sp star alot easer to rewire just 3 wires out less joints doooo |

||||

| aaron sa Newbie Joined: 15/08/2009 Location: AustraliaPosts: 28 |

ok wired in series /paralel . light winds now so only seen 3 amps 12 v chaging . the selceter /gear lever can make a rubing sound if not in corect spot or can take bits out etc depending if need 1 to 1 ratio as this mill is or using the 6.5 to 1 on big slow blade or vertical m might atempt a vertical now just got to cut 44gallon drum in half ,yes will cheak no fumes etc . but what is best way jigsaw or angal grinder?

doooo |

||||

| whirlybird Newbie Joined: 08/02/2006 Location: Posts: 27 |

Dont be a wuss use the angle grinder made for the job old boy and remember bunnings just down the road so you have no excuse to run out of blades. I am because I am.I am not always right but often I am. |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Actually , a circular saw with a thin metal cutting blade is safe and excellant for that job . Those very thin metal cutting blades are very dangerous in a angle grinder ,,they tend to break and you can get damaged very quickly ..I have used 2 of them and was very lucky on both occasions that they failed .(wouldn't be at all supprised if they take them off the market) Nice to see the testing going on ,,,I'm on a different project at present ,,so my motors are sort of looking at me. Aaron ,,if you get a chance ,,see if they perform at 24volts. I don't think you can take the gearbox apart??? If you can will you post a pic of the gears,please? Also ,,any idea what the splines fit ,like what did they come out of might be a good start. Coupling them on a single shaft looks "doable" also I think the main shaft will be able to be 'drifted" out of the main backplate fairly easy ,,have you tried?. Cheers Bruce Bushboy |

||||

| aaron sa Newbie Joined: 15/08/2009 Location: AustraliaPosts: 28 |

Hi bruce thanks at bess gess is planetry gear box . the gear box looks sealed and fixed gear it has a metal seal big bering at back and easy comes away from the plate . it changes gears with the black part shifting splines at magnet end . 1 gear spot it locks the big shaft and middle is 6.5 to 1 next spot is counter rotating big and small shafts gess 12 to 1 could be used for counter rotating props . next spot is both or big shaft in 1 to 1 ratio is how i made the first mill . you could conect this directly (unrewired)to a rectafier in 1 to 1 with a faster around 2.5 m diameter mill for 24 v chaging .will be very easy start when front seal modified . would be exalent mill for lo wind and medium to lo amps but going alot earlier and sinple . the working parts are small so if u got lateth etc could make few in row small body mill . if we use the 6 to 1 ratio then big slow props then it will have to be wired in parell /delta and make alot amps .i have mesured on 1 coil up to 140volt ac but was over 1000 rpm x 6.5 ratio.input .in theiry u could chage 100v batery of 1 coil in that mode and more than likely be over 1 kw for all coils combinned/ mppt coule take advantage of this. to use the small shaft would recomend using the strength of the 30mm shaft with 2 berings on it with spacer inbetween and then the talk to the smaller shaft as dont think it could take sharp yaw on big prop .or unushal but in counter rotating mode a wire or weight to hold the front smaller shaft still and bolt or weld coller on the big shaft .if small shaft still then can use big shaft like that for 6.5 to 1 . even use car central locking autater or wind flap to shift gears . but set up for easy botom line most important average power is take advantage of the easy start and lower power direct drive and very sinple to re wire and mount and very quiet . if u need to do nuts amps then maby few together or in 6.5 ratio or we got to see if is ceramic mag inbetween the molded plastic around lamanates /magnet center part . neo would be ferly easy might be 1 insided or 10??? . then would cut in easer etc.not shore of gear box strength yet is metal outside looks goood for losing some heat but a hole drilled in botom and back case would let more air flow threw it if running hard is unexplored yet .i got plate welded in small shaft to try some thing in 6.5 to 1 soon . not shore what they out of is few theiorys like robotics or washers or industril... .

doooo |

||||

| Page 1 of 2 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |