|

|

Forum Index : Windmills : Windmills for hot water

| Page 1 of 3 |

|||||

| Author | Message | ||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

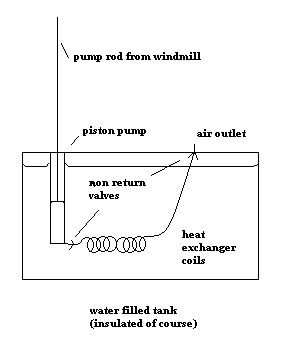

I have a couple of concepts for heating water by high torque, low rpm, variable speed power such as from a windmill. Simply immersing a friction brake in water would provide 100% efficient water heating which might be practical if the friction could be dynamically adjusted to keep the turbine rotor speed at its optimum for the available wind. This concept would be quite practical with a VAWT I think. There could be potentially more than "100% efficiency" by building a machine to extract heat from the atmosphere and transfer this to the water to be heated. A simple way of doing this would be to build an air compressor system that pumped compressed air into a heat exchanger (such as a coiled metal pipe) then released the cooled air back to the atmosphere, for best efficiency the compressor should be immersed in water too so that no energy losses through friction occur. An even better one would be have the wind turbine drive a heat pump although I dont know enough about heat pumps to say how practical this might be. A practical horizontal axis turbine system may be possible using an old well pumping system where a crank at the tower head raises and lowers the pump rod, the pump being something akin to a hand car or even bicycle pump. Note that the outlet valve is a pressure release type adjusted as high as possible without causing the windmill to stall. In theory ambient temperature air is drawn in around the pump piston then then pushed through under pressure into the heat exchanger coils. The compressed air is now hotter than ambient and gives up some of its heat to the surrounding water. As the air is released through the outlet valve its pressure is reduced but now the air is colder than when it went in so energy has been recovered from the atmosphere. Immersing the whole apparatus in water ensures that all friction losses are put to good use heating the water.

Is anyone interested enough to try this out? I expect that in practice it will be more effective heating a larger amount of water just a little rather than trying to bring a small amount of water to the boil. |

||||

| windstuffnow Newbie Joined: 30/06/2006 Location: United StatesPosts: 31 |

Thats an interesting idea KiwiJohn, it might be better if you could use the compressed air for something else as well. For instance driving an air motor to create electric. Another way to create heat would be to use an eddy current heater and submerging it into the water. Basically an eddy current heater is simply a magnetic disc driven in close proximity to either an aluminum or copper plate. Creates lots of heat! Try it on a small scale... small disc of magnets driven by a drill motor and an aluminum sheet... it'll get so hot you can't hold it in a very short time. I built a small 12 pole heater using a copper plate and soldered some copper tubing to the plate. Driving it with my lathe it would heat a 1 gallon bucket of water from around 70 degrees to 140 in a matter of minutes. I'm not sure how it would work on a larger scale but in small scale it's pretty impressive. Have Fun! |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

Ah yes WindStuffNow, an eddy current heater, that would be a neat form of brake and with F&P rotors on hand we already have half of one! The friction brake and the eddy current heaters are most suitable for VAWT I think otherwise we need to get that mechanical rotation down from the top of the tower or else need to pump the water up there. I thought the verticle pump rod did that nicely with existing equipment and techniques. You are right, it would be good to pipe that cooled compressed air away and drive something and so recover even more of the wind's energy. |

||||

| AllanS Regular Member Joined: 05/06/2006 Location: Posts: 67 |

Why not just get the windmill to spin paddles in the water? The energy's got to go somewhere. |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

Couple of thoughts. Compressed air getting warm is fine, but if you have those coils in the (hot) water, I think you'll find that you're going to take more heat OUT of the tank than you put IN. Sure, it'd work while the water is cool/cold, but once the water is hotter than the outside air, you're worse off. A heat-pump where you recirculate the refrigerant, and "cold" is whatever temperature the water is at is a good idea. Eddy-current heater sounds like a good idea - but I wonder if there's nice simple option here? Depending on what the hot water tank is made of, you could *DIRECTLY* heat the tank through induction (eddy-current) heating. Spin the magnets close to the tank itself, rather than using a seperate disc and immersing it all? |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

AllanS, yes that is true, in fact just having the up down motion of the ex-pump shaft agitate the water would raise its temperature. RossW, I agree with compressed air in hot water, that is why I said "I expect that in practice it will be more effective heating a larger amount of water just a little rather than trying to bring a small amount of water to the boil." Any system using spinning or rotation of anything requires either water at the top of the tower or getting rotational energy down to ground level without loosing it all in friction losses, there could be a potential with VAWT types though. Who knows enough about heat pumps and old refrigerator parts to make a heap pump experiment? |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

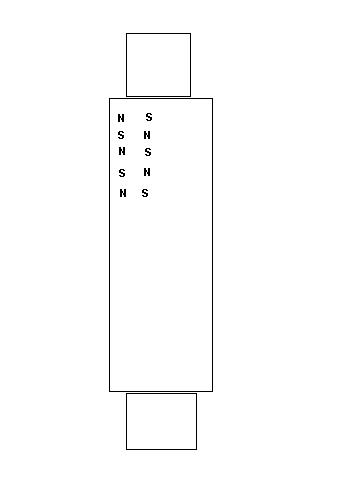

I like Ed's ( Windstuffnow ) idea, "Ed"dy currents.

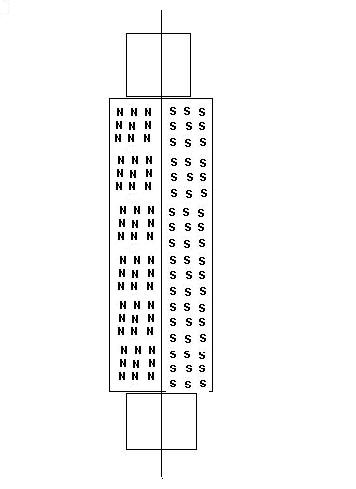

See the drawing...

A set of tightly packed alternating magnets are suspended inside a aluminium tube by the windmill drive shaft. The tube is blocked at one end to keep water tight, and mounted into the water tank, as shown. As the windmill dives the magnets up and down, they will generate a bucket load of heat into the aluminium pipe. The faster the windmill, the more heat generated. And there is no starting problem as there is with a compressor, at slow speed the eddy current load will be small, where a compressor may have to push against a back pressure. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

Gizmo: recropracating (?) motion (up and down) is ok, but you have lots of moving parts, and a HAWT. What if you kept your original idea in as much a a large copper/aluminium tube, but stick it on the end of a VAWT and re-arrange the magnets so as it spins around its axis there is the same rapidly changing field? |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Like this you mean...  The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

'zackery! And you could stack magnets vertically up the shaft to make it longer, thus imparting more energy. |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

The eddy current schemes are another form of friction brake and as such can never produce more than the energy available from the wind turbine. The compressed fluid systems I suggested (either air or refrigerant in a heat pump) have the potential to recover most of the friction heat plus extract more heat from the atmosphere. |

||||

| AllanS Regular Member Joined: 05/06/2006 Location: Posts: 67 |

James Joule worked out the relationship between mechanical work and temperature by getting falling weights to stir paddles in water. A kilogram falling 4 metres will raise a gram of water by about 10 degrees, I seem to remember. But yeah. Getting the windmill to drive a simple heat-pump is an interesting idea... Don't vent the expanded air into the atmosphere but recycle it back to the compressor via a heat-exchanger. Of course, as the water gets hot, so will the vented gas, stuffing your efficiency. |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

AllanS, my original idea was to release the air from the pump directly into the water and allow it to bubble to the surface presumably transferring its heat to the water as it rose, i.e. no heat exchanger coils, but the water container would have needed to be pressurised and it still needed a pressure release valve. Moreover I realised that the escaping air would be of very high humidity which would carry much of the heat away. If one was to recycle the air back to the compressor it would be more efficient to use a more suitable fluid, which is exactly what a heat pump would do. My gut feeling at this time is that the simple system would work but the compression ratio would need to be very high so that the temperature of the compressed air would he bigh and the temperature gradient though the heat exchanger steep enough to provide useful working temperatures. |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

I'm hesitant to mention it here because some "damn fool" will go off without thinking it through and blow themself up but hey, *we're* all careful, arn't we? <grin> LPG (yes, the same stuff you run the bbq on) is actually a great refrigerant gas, working on relatively low pressures with quite good expansion characteristics and a liquid at quite practical working pressures. It's also cheap and easy to get hold of and doesn't require expensive and hard-to-come-by seals like many of the freon-free R12/R502 etc replacement gases. |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

Well shucks and goodness gracious, whoever would try a thing like that?

But if they were I wonder what compression ratio they would need, something like 8:1 might be effective? |

||||

| dave r Newbie Joined: 19/04/2006 Location: AustraliaPosts: 11 |

Can I take the moving magnet idea a step further. I make biodiesel. This requires heating oil to about 50 deg C. At the moment I use a s/hand electric hotwater unit to process the oil. Just having a look at the above drawings, what would happen if I took one of those old gas hot water units (the one's with the flu down the centre) and had spinning or reciprocating magnets inside the the flu. What sort of air gap is needed between the magnets and the aluminium or copper sheet. Regards dave dave rankin |

||||

| windstuffnow Newbie Joined: 30/06/2006 Location: United StatesPosts: 31 |

The closer you can get them Dave the more heat you'll get. You do need to consider the temperature you'll be running it against what the magnets can handle. I don't remember the max temp on the N35's but I believe its in the range of 175 deg F. |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1636 |

Hiya Guy's, Well after reading this post I got the bug and I'm making up a prototype. The photo shows the shaft I've machined up and the alu tube which is 1-1/2 diameter with a 20 mm bore. I've machined the shaft to 19.8 diameter so there will be .1 mm clearance on the radius. I've got 140 odd 3x3x3 n40 neo's which I intend to embed in the shaft so they sit flush with the top. Now the question is which is the best way to arange the magnets? I was thinking of North- South vertically and have the magnets sitting next to being the opposite pole. I reckon if I get it right it should make a beaut immerson heater and I can trial different rpm for temperature measurements.

In the arragment shown below is my idea but I'll need some advise whether this is the best way.  |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

Bryan, I take it you are going to rotate the shaft (i.e. not reciprocating)? I think it would be best to have the magnets in parallel, that is with all the N poles adjacent and of course all the S poles adjacent, Making in effect just one big magnet. My reason for saying this is that you want the lines of flux to travel through the aluminium but if you have the magnets side by side a goodly portion of the lines will join through the touching surfaces of the two magnets and quite a few will squeeze through the .1mm gap too. |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1636 |

Hiya KiwiJohn, Is this what you mean, basically cutting thru the centreline 1 side is north and the otherside is south. Or would be better to do the poles in 90 degree quadrants?  |

||||

| Page 1 of 3 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |