| Author |

Message |

Peppercorn

Newbie

Joined: 10/02/2010

Location: Posts: 2 |

| Posted: 12:48am 11 Feb 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi this is my 1st post here but I have been reading all of the projects for the last few days off and on and I'm really impressed.

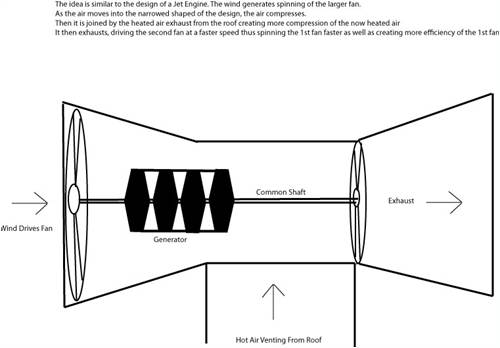

Anyway I wanted to try and design something that would incorporate the heating of air from within the roof here in Qld with a wind generator.

I have come up with this very basic design.

I'd like to know what you think??

|

| |

MacGyver

Guru

Joined: 12/05/2009

Location: United StatesPosts: 1329 |

| Posted: 05:38am 11 Feb 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Peppercorn

Welcome to the forum.

If you are trying to ventilate your attic space, you'll find what you've drawn will more than likely push air into your attic space instead of drafting it out.

Heated attic air will rise due to its lessened density (hot air rises). This alone will do the trick, but you need to use a larger "out" side (exhaust) so air flowing through will be first confined, then led into an area of greater volume and hopefully, less pressure. Basically, you'd want to build what is called a "venturi".

If you were to build a "T" atop the roof penetration (similar to what you've drawn here), such that it could pivot with changing wind direction by incorporating a "fin" or "tail" and an expanded exhaust, it would probably work.

For the money, I'd merely invest in a commercially-manufactured, round, spinning "roof turbine". Those are the little onion-shaped, spinning things regularly seen on commercial buildings' roofs.

if your goal is to use the rising warm air to augment driving turbine blades, I think you're in for some disappointment. Still, it might be a fun project. I think I'd try it on an out building first, before I punched a hole in my dwelling's roof though!

Best wishes.

Nothing difficult is ever easy!

Perhaps better stated in the words of Morgan Freeman,

"Where there is no struggle, there is no progress!"

Copeville, Texas |

| |

KarlJ

Guru

Joined: 19/05/2008

Location: AustraliaPosts: 1178 |

| Posted: 08:32am 11 Feb 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

diameter of the duct will need to be 3m and about 15m high off the top of the roof.

duct will be 300mm diameter from the house and to support that thing on top it will need to be HEAVY.

Its a nice idea and we've all thought of it but unfortunately it will make power during a hurricane only.

Two fans isnt helping unless you add some kerosene!!!!!

on ya

karl

Luck favours the well prepared |

| |

Peppercorn

Newbie

Joined: 10/02/2010

Location: Posts: 2 |

| Posted: 08:40am 11 Feb 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Well, I am somewhat deflated but I will still probably build it and learn for myself.

Karl, Why does it have to be 3m in diameter and 15m high??

I don't get that.

MacGyver.....We call them Whirlybirds and I have 2 on my roof, which spin continually.

My idea, if I didn't explain it well enough was to try and incorporate the heat exiting from the roof into a wind generator, hoping to not only kill 2 birds with 1 stone but making the wind generator much more efficient. |

| |

KarlJ

Guru

Joined: 19/05/2008

Location: AustraliaPosts: 1178 |

| Posted: 08:47am 11 Feb 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

lots of turbulent air over the top of the roof and to get enough capture area you need diameter, 3m is good

Luck favours the well prepared |

| |

KarlJ

Guru

Joined: 19/05/2008

Location: AustraliaPosts: 1178 |

| Posted: 08:56am 11 Feb 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

just takin the piss a little, 5m would probably do it but 15 would be better

WHat sorts of sizes did you have in mind?

I think the venturi effect would work well enough to draw the hot air out but I dont know how much energy it would add, from my rough calculations it would be diameter x temp difference x airflow = 0..

Luck favours the well prepared |

| |

angus

Newbie

Joined: 08/12/2009

Location: AustraliaPosts: 7 |

| Posted: 12:31pm 11 Feb 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Peppercorn.Welcome to the forum and please do not feel deflated

Dont mind KarlJ- he means well but (being an Aussie) he has a wicked sense of humour.

So let's take your idea a step at a time.

"Wind drives fan". It therefor must slow down on the other side of the fan (otherwise no power will be extracted).So how can this wind now be compressed in the "narrow shape"?

But let us allow that it will compress.

We now have compressed air in the narrow section .

What is stopping this compressed air from forcing its way down the "hot air vent".As Macgyver has pointed out there will be no "venturi" affect here.

But let us allow that your idea will work as planned.

Are you prepared to fabricate such a "cone-to -cylinder -to-cone " construction?

Are you then able to cope with the engineering required to allow it to track the wind?

Are you prepared to mount it to the top of your roof -with all the attendant noise issues?

But most importantly- will your neighbours put up with a constantly swivelling "conical-cylinder".

If I was your neighbour I would not!

So mate -again welcome here and please continue to contribute.

That is all we mere mortals can do.

Angus.. (The older I get, the better I was). |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 01:41pm 11 Feb 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

You might have 1/2 a chance of doing something similar with using a vawt.

Once again the size required would be an issue or the power generated would hardly be worth the trouble.

Then you have the other issues that Angus pointed out.

Think best to add another whirlly or 2 and a solar panel and you would be in front on both accounts as well as cost.

Still good to have a new input and another thread on an idea to think about.

Dont be discouraged, just rethink and move forward,

If you look on ebay there is some similar products with out rageious claims that must sucker a few.

Many here have squeezed the wind in every way practical to gain that little bit more and know just hard it is to make it work. (or not work in many cases)

We also discuss our failures with the hope that another dont waste the time we have to prove it dont work.

We would be a sad lot if we said nothing and let you spend the time and money to tell us what we already know.

Pete.

Sometimes it just works |

| |

bobshau

Newbie

Joined: 22/11/2009

Location: United StatesPosts: 27 |

| Posted: 01:48pm 11 Feb 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Peppercorn,

Your concept is a good candicate for a small scale test.

It reminds me of the small scale tests I ran years ago when I was first bitten by the windmill bug. I tested the venturi concept to see if it would enhance the flow of air through the turbine blades. It looked like yours without the twin turbine and without the injection of hot air in the vena-contracta.

The test showed me that the addition of the venturi made the blades slow down because the approaching air seemed to bypass the whole apparatus rather than go through the venturi.

I learned that making a bigger set of blades without the addition of a non-conventional enhancement was a better approach.

As a result, I built a 20' diameter windmill. Operation and repair of this machine over the years has convinced me that simple is good. There is much to learn about keeping a working machine in the air without breaking something, or having it burn up.

If you decide to go ahead with your concept, I recommend that you build a small scale "cardboard" test to help demonstrate it's feasibility. Also, please let us know what you learned.

Blessings and peace,

Bob

BobS |

| |

GOFJ

Newbie

Joined: 22/12/2009

Location: AustraliaPosts: 27 |

| Posted: 01:42am 12 Feb 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

As there is a greater volume of air passing the rear fan it will need a greater pitch angle, a larger rear cone will also assist. The torque available will be pretty small (my guess) but it should give good forced ventalation to the roof cavity. Look at the fan angles in jet turbines, also look at the massive reduction in turbo prop engines as well as the pitch angle of the back fan that is connected to the gearbox (the reason for my guess).Edited by GOFJ 2010-02-13

Jack |

| |