|

|

Forum Index : Windmills : 7th Oct 07. Dual stator windmill.

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Hi all. Finished the dual stator windmill this weekend. I re-wired the two stators in a staggered configuration as discussed in this thread http://www.thebackshed.com/windmill/forum1/forum_posts.asp?T ID=749&TPN=1, then gave them a good coating of clear varnish to protect against the weather. The stators are not decogged, and its a 3 phase arrangement, but I was pretty sure the large turbine would overcome the cogging.

Next I bolted them to the new nacelle. The shaft has had its spline extended by Trev ( See his web page, click on his Windmill Parts page. http://www.thebackshed.com/foundryandfibreglass/)

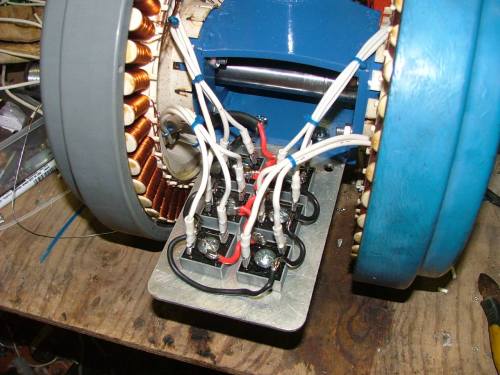

Then I connected the 4 3phase rectifiers.

And lastly the finished windmill was put up on the mast. I used my new 6 blade turbine ( see http://www.thebackshed.com/windmill/forum1/f orum_posts.asp?TID=744&PN=1 ), this has been driving a single stator for the last week and made more power than the stator could handle, a few times I saw the power peak at 8 amps but the turbine continued to speed up, the stator was a 7 phase 3 pole 60 series wire, so was working pretty hard.

Initial results look good. In a light wind the mill was feeding just over 1 amp into the 12v battery bank, and started easily. Later when the wind picked up I saw 15 amps a few times. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| CanTinker2 Newbie Joined: 21/01/2008 Location: CanadaPosts: 14 |

Hi Glenn I plan to use a decogged single stator using your stator design with 1 set of 5 poles and 3 sets of 3 poles. Above you mention your new 6 blade design was too much for a single stator. Would you suggest moving to a 3 blade design or stick with a 6 blade design and shorten the blades a bit? I have 0.94 m of 8 inch pvc pipe that should nicely make a smaller version of your 6 blades. Also have you ever heard of using sealed bearings instead of brushes. I have seen bearings epoxied to a wooden pipe, the outer race was held by a straight peice of wood running parrallel to the shaft. The bearings had nuts welded to the inner race and outer race to connect the wires and to the wood strip. These were only being used for a couple of amps for the application, but had very low impedance and stould up very well over time. I have never seen this used since, however it would be simple and inexpensive. Thanks John |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Hi John I went for 6 blades because I have terrible wind conditions here. I wanted a slow running turbine with lots of torque that would use the wind available to make a few amps for most of the day instead of a fast running turbine that would make a lot of amps once a month! It is working well. Peaks at 15 amps, less than other mills I've tried. But its just always running and even in light wind I see an amp or two. If you go for a 6 blade turbine, using your 940mm PVC on extensions from center of 260mm, giving you a diameter of 2.4 meters, then you wont need to decog your stator. The turbine will have enough torque to start a standard stator. I run two standard stators on my dual and the turbine has no problems starting. Yeah I can see bearings would work OK as brushes, but I dont know if they would last very long. The arcing between the balls and races would soon wear down the chrome and any hardening, and then the bearing would loose its tollerance quickly. It would be OK for very low currents, but I'm thinking much less than 1 amp. Glen The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| madteckhead Newbie Joined: 04/07/2008 Location: Posts: 6 |

Hi Looks like a great mounting frame!, Any chance you can post some details on how it fits together / parts, etc. Would be very useful as am trying to find a low cost solution with only a small amount (or no) welding required. Cheers, Nathan |

||||

| BarkyJ Senior Member Joined: 26/04/2018 Location: New ZealandPosts: 114 |

Hi Guys Digging up this historical post - sorry about that. I am just trying to find more information about this 'nacelle' chassis. Glenn do you have plans available for this? I can see some more about it here: http://www.thebackshed.com/forum/forum_posts.asp?TID=744&PN=1&TPN=1 I found your kit which you provided the DXF's of, for your single stator version, which I am assuming came sometime before this dual stator version? Do you have any plans you can share, especially around this nacelle for dual stator? Also - the drive shafts, I have seen the joined shafts from Trev. These seem to be the older type shafts though, for the White/Grey caps, not the black ones. Is anyone in NZ joining the later shafts? Thanks |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Hi Barky Sorry no, no longer have the plans for that nacelle. It was a one off design to suit a resplined shaft. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |