|

|

Forum Index : Electronics : Sig Energy Topic

| Author | Message | ||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1247 |

As Pete suggested (thank you  ) I am starting a thread on the Sig Energy products in the hope some will add to the information bank here whilst others can learn a bit more about the Sig systems apart from what sales tell you. ) I am starting a thread on the Sig Energy products in the hope some will add to the information bank here whilst others can learn a bit more about the Sig systems apart from what sales tell you.I am not an authority at all on Sig products, far from it, but after just a few days I have learnt a few things about its performance. Here is a link to my inverter topic where I started to discuss the Sig system that we have just installed. There are a few posts and some graphs and discussion there, that should have gone under this new topic here. Specifically relating to the systems own consumption from the battery reserve which for a 25kW inverter and 48kWk of storage appears to be at least ~400W. So you can read a bit more on how this discussion started with the above link. The Sig information there also was polluting my own inverter topic thread. I have a sense that Sig System will be a popular product in the Australian marketplace as it gets a foothold. Yes there have been issues with the single-phase inverters that I think covered their 6 - 12kW units and which has been blamed on "installers" not terminating some connectors correctly. I understand that the output of affected controllers have been throttled back to minimise any further heat damage whilst replacement inverters are being sourced for a retrofit. I hope we hear more detail about the actual problem with some pictures of the resultant damage and comparisons of what a good termination and a bad one actually look like. Most installers I have met are quite knowledgeable to the point of being anal about their installation, surely the information must have been misleading or ambiguous for them to have got something so basic so wrong? The main feature of the Sig system that drew me in was its simple modular design. Each battery module has a nominal 8kWh of storage capacity. The modules have a connector that mates with another that can be either above or below it. The inverter mates with the top connector of the last battery module by just plonking it on top. So you only purchased 16kWh but you now realise you need 24kWh? sure, just lift the inverter up off the top battery module and slide another battery module in place and put the inverter back on top again voila job done! No wiring needs to be changed/touched, all the modules internal connector/bus system take care of that. Edited 2025-12-21 22:44 by wiseguy If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| Godoh Guru Joined: 26/09/2020 Location: AustraliaPosts: 600 |

Hi Mike, I am wondering what made you decide to go with commercial gear, and if you have fully moved away from home made stuff now. The stackable battery systems sound like an easy way to expand the system if needed. Does the inverter get hotter as it is mounted on top of the batteries, or do the batteries run cool all the time? It will be great to hear more as time goes on about the system. Thanks Pete |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1247 |

My friend & colleague sent me a copy of his quote for a system install here is the quote: EnergySA-Solar_Quote-Korb X.pdf I must admit after reading the document and seeing the ability to charge your car, transfer energy from car to system and its ability for relatively simple expansion I was seduced. Of course, my house was setup for 3 phase which was a way of sending excess solar to the grid, up to 15kW, which was great when the FIT was 20c/kWh & life seemed good. Then of course over a few years (since beginning of 2020) the FIT has incrementally reduced to bugger all, some providers actually charge you for any grid feed in. Up until the beginning of this year we have not paid one cent for electricity since 2020 due to the bank of credit we had built up. The energy company we were using, Engie, now have a "great" continuous feed in tariff but they charge $2.193 per day for the poles & connection to their supply, they have a peak time usage rate of 68.926c/kWh. This equates to ~ 730kWh I need to feed back to the grid just to break even with the supply/connection with no usage added yet. Sure, there is another supplier that charges $1.01 a day for connection/supply and their FIT is 5c/kWh, which still equates to over 600kWh/month to break even. I am gambling that I won't need to import any energy on going so now I'll try to cash in on the 9c FIT whilst it lasts. I'll post this now before I lose it...... If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| phil99 Guru Joined: 11/02/2018 Location: AustraliaPosts: 2882 |

Always press Ctrl-A then Ctrl-C before posting. If your post gets dumped log in again then press Ctrl-V in a Post Box. |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1247 |

That is a good plan - I resorted to using note pad and then copying and pasting but sometimes neglect that and then regret it. Doing a copy before posting is a simple safeguard! Cheers If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| Godoh Guru Joined: 26/09/2020 Location: AustraliaPosts: 600 |

Hi Mike that looks like a great deal. I am totally out of touch with grid prices, I have been off grid for so long now. But when I was working as a contractor the prices were nowhere near as high as they are charging now. The daily connection fees are pretty steep. Plus their rates for peak are outrageous. From memory here the connection fees were around $1 a day and the normal rate for power was around $0.25 cents and there was a special rate for hot water and heating that was about half that. It seems that privatising the energy market has done us a dis service as usual and prices have gone through the roof. It will be great to read the updates and to see how the system works cheers Pete |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1247 |

The stackable battery systems sound like an easy way to expand the system if needed. Does the inverter get hotter as it is mounted on top of the batteries, or do the batteries run cool all the time? Hi Pete, I'll never move away from tinkering with electronics its a part of my DNA. I have a number of quality old school VCR/DVD players, speaker-boxes, direct drive turntables, Amplifiers to refurbish/repair that I may never actually finish them all, plus a heap of inverters commercial and home-made, whose future has not yet been determined, along with an ever-growing number of inverter toroids, ring chokes enclosures heatsinks. In an earlier life when money was tighter I found it easy to accumulate but hard to throw stuff out, breaking old habits doesn't always come easy. My wife keeps on pointing out that my workshop is beginning to look like Steptoes junk yard lol. I am now going to begin a cull of things, keeping only the really good stuff. I also have a plan to complete a benchtop switch-mode power supply design I started to design at the beginning of the inverter project. Its requirement was at least 60V @ 25A I have all the boards etc ready for assembly gathering dust for 4+ years. The batteries all seem to from run mildly warm on a pleasant day to very warm on a hot day. The inverter/MPPT charger module (on top) runs at least 20 degrees above ambient most of the time, I'm sure the already warmer battery modules don't help. Edited 2025-12-22 16:36 by wiseguy If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| KeepIS Guru Joined: 13/10/2014 Location: AustraliaPosts: 1993 |

Hi Mike, I was wondering about the Battery modules and how they might build a system that was economical, and handle various battery bank voltage/power levels as they were stacked in various power configurations in an installation for a given Inverter & solar controller. If the battery compartments are anything but cold (ambient temperature) then each battery box must have a high voltage generator inside with each output being paralleled as extra banks are added, something you suggested earlier on, unless I misunderstood. Similar to some quality smaller 5/10kw HF inverter on steroids. I have around 36kW of LiFePO4, the batteries run cold with a 14.6 kW load on the Inverter (no solar), as does the BMS. The balances shunt power around between cells in a bank, so only consume power internally from the battery cells as a result of the cell levelling action, and these can run slightly warm at a few Amps of balance, but that's with some suspect Cells a few years old and the bank close to 90% SOC, with a new system they should hardly be running. NANO Inverter: Full download - Only Hex Ver 8.2Ks |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1247 |

If the battery compartments are anything but cold (ambient temperature) then each battery box must have a high voltage generator inside with each output being paralleled as extra banks are added, something you suggested earlier on, unless I misunderstood. Similar to some quality smaller 5/10kw HF inverter on steroids. I have around 36kW of LiFePO4, the batteries run cold with a 14.6 kW load on the Inverter (no solar), as does the BMS. The balances shunt power around between cells in a bank, so only consume power internally from the battery cells as a result of the cell levelling action, and these can run slightly warm at a few Amps of balance, but that's with some suspect Cells a few years old and the bank close to 90% SOC, with a new system they should hardly be running. Hi Michael, When I spoke about warmth of the battery I should have been more specific as I was referring to the whole battery module, which of course contains the batteries and I am guessing also has some voltage conversion, bi-directional power transfer circuitry, which I reckon causes the heating of the whole module and hence the battery. Given the expected ultra-low impedance of a 270 A/H battery, I would not expect the battery itself to be the cause of any heating it just got hot as it was along for the ride with the other less efficient circuitry. I also suspect the batteries which have apparently a 4kW rating for each 8kWh module are identical for each and every configuration. I suspect the power limiting is just a software value in the inverter that can be preset for the inverter rating, I wonder how different the 6/8/10/12kW units really are? Maybe they do what we did, I created a range of power supplies with various current outputs but 100% identical circuitry and components. The software either allowed 13.6V @10A or @15A and if they paid more money we released an extra 5A. That meant we only had a common design and one type of unit to make and we would only do the final testing and labelling after loading the software required to meet the order. As far as the battery goes, for their various power configurations, the batteries only come in 8kWh increments and a 4kW limit per module. If they are creating ~ 30W of heat for their 4kW rating that means the circuitry run at ~99% efficiency. Maybe I was a bit misleading when I said that they were 10 or 20 degrees above ambient as given their 80kG bulk meant their thermal inertia ensured a slow drift back to ambient? Also the 30W loss was lightly loaded over-night, maybe as the power transfer has the wick turned up during bulk charge or heavy discharge the losses increase to maybe 200W at 4kW in (or out), still around 95%+ efficiency? hence their being quite warm to touch. I hope that addressed your query or maybe I misinterpreted what you were asking? Edited 2025-12-22 22:11 by wiseguy If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| gaspo Regular Member Joined: 25/06/2018 Location: AustraliaPosts: 67 |

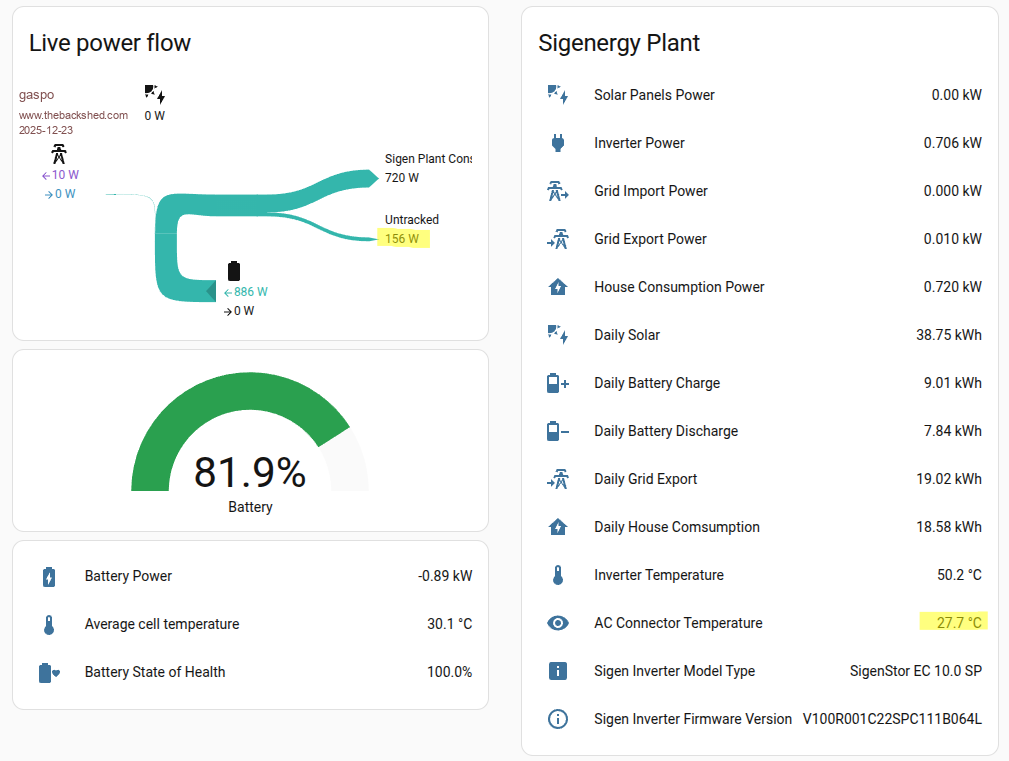

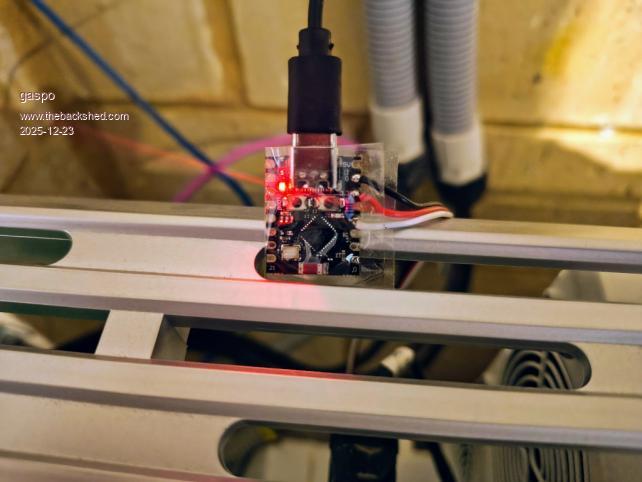

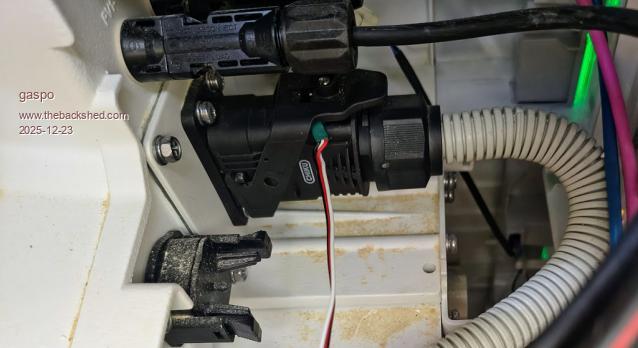

I also made use of the government battery rebate and chose a Sigenergy system. My installation consists of a 10 kW single-phase inverter paired with a 24 kWh battery, which has been running since October. The system includes three strings, each with twelve 440 W panels connected to the inverter, sized to meet winter demand and allow for future EV charging. Like other owners of SP inverters, I’m expecting a replacement sometime early next year. So far, the inverter’s AC connector has shown no signs of overheating, even under sustained loads of 4–6 kW, with connector temperatures typically remaining below 30 °C. The replacement inverter is expected to come with a 12-year warranty rather than the standard 10 years, and hopefully the company will be around to support it long term. Beyond the mobile app, I use Home Assistant, which pulls data via Modbus over Ethernet (enabled by the installer during commissioning). I’ve also built a simple temperature monitoring setup using an ESP32-C3 and a DS18B20 sensor attached to the inverter’s AC connector. In Home Assistant, I’ve configured an automation to send alerts to my phone if the connector temperature exceeds a set threshold. The battery cell temperature generally sits around 30 °C. Overall system self-consumption ranges between 150 and 200 W, averaging roughly 170 W.  |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1247 |

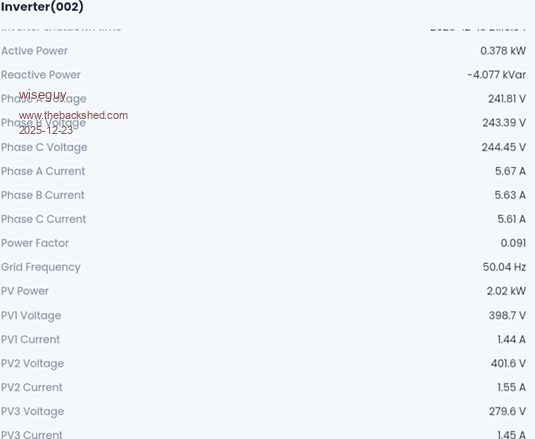

Hi Gaspo, thanks for your post and the information, isn't it great to see "0" imported power  . I like your add on to keep track of the connector temperature - I haven't had the top cover off mine yet - probably the first thing I've ever owned and not done that . I like your add on to keep track of the connector temperature - I haven't had the top cover off mine yet - probably the first thing I've ever owned and not done that  . I assume that was required to get access to the connector in question? I was not aware modbus was an available option over the ethernet, you made good use of it. Does the ESP32 retransmit the inverter information via WiFi with the combined inverter plus your temperature value? . I assume that was required to get access to the connector in question? I was not aware modbus was an available option over the ethernet, you made good use of it. Does the ESP32 retransmit the inverter information via WiFi with the combined inverter plus your temperature value?I also made an incorrect assumption that the gateway unit was the WiFi point for the Sig, but the inverter itself has a WiFi antenna, so it appears the gateway communicates over I am guessing canbus or modbus or ethernet, data back to the Sig inverter for WiFi relaying? I went out late last night to see the dormant temperature of my system around midnight. The adjacent brick wall at the base of the inverter was at 20.4 degrees, the bottom module was 21.2 degrees. Each module was another ~0.5 degrees warmer, the inverter at the top was at ~24.5 degrees. So was there some heat growing from the bottom to the top or was the main heat at the top and reducing as it travelled downwards or probably a bit of both? My comments about module & inverter heat thinking back, was just after dusk with the house aircon running (average 5+kW) so not a surprise for the Sig system to be noticeably warm at the time after a hot day. This morning I took a look at the inverter data page and noticed some weird information. Maybe Gaspo (anyone?) can tell me what it is up to, here is the page;  The house load was about ~380W at the time yet phase 1,2 & 3 all have ~5A of current at ~240V the reactive power was ~4kVAR, reported power factor was ~.091, which when multiplied by the ~4kVAR equates to the ~380W of consumption. Does this mean that the energy authority is supplying ~4KW of reactive power for my 380W load? I hope so lol its about time we got something for nothing back from them, but seriously if this is correct and there are many installations going in there will soon be a grid problem ? If its true whereas previously home owners are not hit for their reactive power, maybe this will cause change ? Edited 2025-12-23 08:07 by wiseguy If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| gaspo Regular Member Joined: 25/06/2018 Location: AustraliaPosts: 67 |

There is no need to remove the plastic cover. The back of the inverter, where all the connectors are located, is already open and can be accessed by hand from the rear. The temperature module I built is independent of the Sigenergy data. It uses an ESP32-C3 running MicroPython code and publishes temperature data via MQTT (over WiFi) to Home Assistant. In Home Assistant, I defined a new sensor that subscribes to the MQTT topic published by the temperature module, and this sensor is displayed on one of the dashboard cards.   Yes, the WiFi module is integrated into the inverter and uses a version of the ESP32. The gateway connects to the inverter via an Ethernet cable, while the second Ethernet port on the inverter is used to connect to my local network. Modbus over Ethernet also works when the inverter is connected only via WiFi. The house load was about ~380W at the time yet phase 1,2 & 3 all have ~5A of current at ~240V the reactive power was ~4kVAR, reported power factor was ~.091, which when multiplied by the ~4kVAR equates to the ~380W of consumption. I don't fully understand how various AC powers work in the grid connected inverters. So I asked ChatGPT for inverter power analysis of my data: Active power: 2kW Reactive power: -1.7kVar Phase A current 11.5A Phase A Volts: 243 Power factor: 0.755 1. What each value means Phase A Volts: 243 V Normal Australian single-phase grid voltage (230 V nominal, ±10% allowed). Phase A Current: 11.5 A The RMS current flowing between the inverter and the grid. Active Power (P): 2 kW This is the real, useful power that actually does work - Running appliances - Charging batteries - Exporting to the grid Formula: P=V×I×cos(φ) This is the power your meter bills for. Reactive Power (Q): −1.7 kVAr Reactive power is power that oscillates back and forth between the inverter and the grid and does no net work. It comes from: - Inductors (motors, transformers) - Capacitors (filters, inverter output stages) Power Factor (PF): 0.755 Power factor tells you how efficiently current is being used. Formula: PF=P/S Where: P = Active power (kW) S = Apparent power (kVA) A PF of 0.755 means: Only ~75.5% of the current is producing real work The rest supports reactive power 2. What does negative reactive power mean? This is the key point. Sign convention (very important) For grid-connected inverters (including Sigenergy): Reactive Power Meaning Positive Q (+) Inverter is absorbing reactive power (inductive, lagging PF) Negative Q (−) Inverter is supplying reactive power (capacitive, leading PF) 👉 Your inverter is exporting capacitive reactive power to the grid. In plain English Your inverter is acting like a capacitor - It is pushing reactive power into the grid - This helps support grid voltage (lowering it when it is above 230-240V range) - This is intentional behavior, not a fault. 3. Why is the inverter doing this? Modern grid-tied inverters (including Sigenergy) are required to provide grid support: Common reasons: 1. Volt-VAR control enabled When voltage rises, inverter injects capacitive reactive power This counteracts inductive loads on the grid 2. AS/NZS 4777.2 compliance Australian standards require inverters to: Adjust reactive power automatically Support voltage stability 3. Local grid conditions Light load, lots of solar nearby Grid voltage drifting high → inverter responds 243 V is slightly on the high side, so exporting −1.7 kVAr makes sense. 4. Why is the power factor not close to 1? Because: - You are exporting reactive power intentionally - Reactive current increases total current - PF drops even though nothing is “wrong” This is normal and expected for grid-support mode. 5. Is this bad? Should you worry? No. - Residential customers are not billed for reactive power - The inverter is operating correctly - This actually helps the grid Unless: - Your inverter is hitting current limits - Or you see export clipping due to excessive VARs In normal operation, this is fine. |

||||

| analog8484 Senior Member Joined: 11/11/2021 Location: United StatesPosts: 182 |

The battery pack idle consumption seems rather high. I wonder how that impacts the HV vs LV battery/inverter efficiency comparison. It would be interesting to know what FET's are used in the bidirectional DC-DC converter. For comparison, a Tesla Model 3 only requires ~200W idle consumption for the entire vehicle with a ~300kW+/~74kWH battery pack. One key difference in the pack is that it's in 96S configuration. Edited 2025-12-24 03:21 by analog8484 |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1247 |

Yes, the WiFi module is integrated into the inverter.... 1. What each value means.... Modern grid-tied inverters (including Sigenergy) are required to provide grid support: Australian standards require inverters to: Adjust reactive power automatically Support voltage stability.... Hey Gaspo, thanks for taking the trouble for the detailed reply with a host of useful information & clarification. The main take away for me was the requirement for installations now being required to correct for reactive power autonomously, that was a surprise for me. And yes I missed the "-" sign of the reactive power, that should have given me a clue. I had pictured the connector issue to be a PCB type connector not a panel/inline pluggable type - I assume that is what is hiding underneath all that shrouding? Interesting that I have essentially managed to reduce my energy requirement from the grid to zero, all I need to pay for now is the daily connection fee. As part of this wonderful new deal with the "grid", it appears that at the time when my house was consuming maybe 400W, my inverter was hard at work compensating 1.7kW of energy to fix a grid issue and which I am also paying for that "privilege". Maybe I am seeing this wrong ? Edited 2025-12-24 10:13 by wiseguy If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2025 |