|

|

Forum Index : Electronics : Nano Power Inverter - Roll Your Own Style

| Page 1 of 16 |

|||||

| Author | Message | ||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1236 |

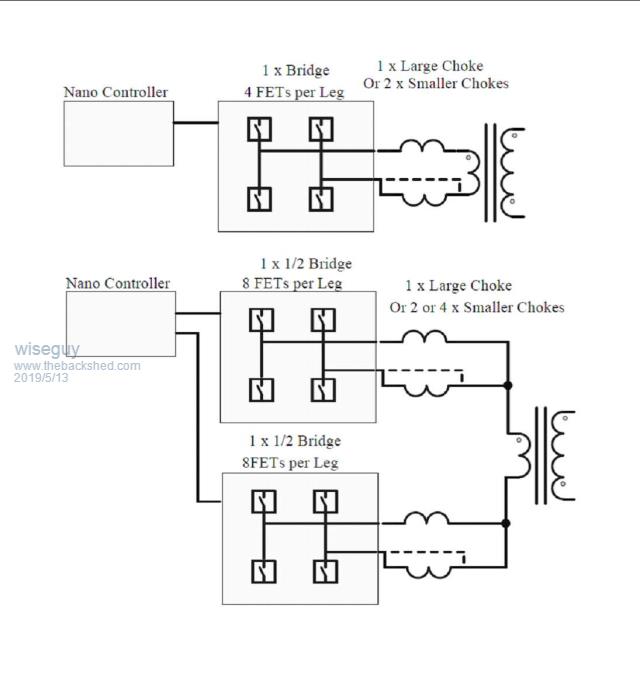

The time has come to fully commit to creating my homegrown inverter. My aim is to create a reliable power platform that is relatively simple to reproduce with a minimum of pyrotechnics and a medium skill set. Converting from a 48V nominal input to a high frequency multi kW 230VAC inverter is a very demanding & challenging task with multiple tradeoffs and often conflicting requirements. It has challenges in the mechanical domain as well as electronic. My only claim to fame so far is a measly sinewave inverter of 250W. This may be the beginning of a long journey...... I was going to create this project quietly in the background so I would not have to fess up to any self induced errors & catastrophies, but decided to create an online diary of the progress and setbacks along the way, maybe it might at least inform others what not to do.. A catalyst to starting now was finding 2 x Toroidal Transformers for sale 2 weeks ago on Ebay, I made an offer of $180 delivered to Adelaide which was accepted. The listing described them as 2 x 5Kw 230V/32V Toroids. They have labelling that suggests they are from a 48V - 230V inverter. I feel like maybe I have wimped out by doing this, but I quote from Clint Eastwood's "a mans gotta know his limitations". I was not looking forward to winding the toroids, and this seems like a neat solution if they work out. Maybe I will still need to rewind them any way, but hopefully not. A number of design considerations helped the project to take shape. One was, what is the good of making it work great if no one else can benefit from it because it is just too hard to build/reproduce. 1) No SMD Parts - designed to use all through hole parts. If it works as I hope & anyone wants to also build one, they dont have to contend with SMD parts. 2) Full galvanic isolation between the control PCB and the Power PCB. This includes isolated power supplies for the 2 x high sides, and 1 for the 2 low side bridge legs. Bridge drive is via 2 optocouplers "Warp" style parallel inverse driven to ensure each side cannot be commanded upper and lower on at the same time. The upper and lower FETs' are driven alternately as one opto is driven off and into reverse to turn the other opto on. Both Fets on is catastrophic - if it ever occurs, we just need to ensure enough dead time to ensure that first FETs are fully off before the next ones turn on. 3) Relatively simple construction mechanically and electrically. In its simplest form with no bells and whistles only 6 wires are required from the Nano board to the FET Power module to drive the power stage completely, 1 x 12V pair and two pairs of Opto drives. If the isolated supplies are powered from the 48V then only 4 wires are required ! 4) I incorporated negative bias into the lower bridge FETs to provide better immunity to dv/dt gate issues. This is experimental, I will start with -5V and if required then try -12V, if it proves to make not a twit of difference it can easily be left out/unused by inserting a PCB link. 5) For bus capacitors I decided to house them on 2 x separate PCB's, each PCB will employ 4 x low impedance 10,000uF 63V capacitors. The capacitor PCB's screw onto each end of the main FET PCB using 6 high current standoffs per PCB. They can be easily removed and the inverter run without them as required for testing. 6) For the Gate drive isolated Power supplies, I have created 2 x PCB's. One uses 3 (or 4 for - bias) of the little Ali modules, the other is for a home grown single transformer with 4 simple 20 turn windings and a little IC to drive it. Either can be used interchangeably. Both isolated modules incorporate an "off" function to turn them off when the Nano commands a halt to the inverter. The home grown version uses 12V from the Nano board to create the isolated supplies. The main PCB can be configured to use the 48V bus to Power the "Ali" version. 7) Keep the gate drives relatively short & local and low impedance. The Power PCB is 100mm wide x 260mm long with 16 FETs. This meant that I could incorporate a local FET drive buffer driven by high speed power opto couplers. The longest trace for the Gate drive is around 100mm. 8) I am not keen on using the heatsinks for the high current connections. The output stages can be configured easily though to do this if desired. Part of my reasoning is that the oscillations sometimes caused by paralleling multiple mosfets can often be fixed by putting a Ferrite bead on the drain leg. Of course when the mosfets are all bolted to a common heatsink there is no longer an option to fit the ferrite bead. There is much analysing still to be done on this after the prototypes are assembled. 9) Two power boards can be utilised for real thrill seekers, each as a half bridge configuration with 8 x High and 8 x Low side FETs in each LEG. Both half bridges can be further configured into two groups of 4, allowing 2 or 4 smaller chokes that are then combined, instead of 1 massive choke. 10) I chose to use my own version of a Nano1 controller PCB to provide the 1 x 8 way connector for a single Power board or 2 x 8 way Half bridge connectors. It also user different circuitry for voltage control and over AC current shutdown. I currently have no thermal fan system employed I will probably just employ some cheap Ali modules for Fan Control and Amp & Volt and Watt displays as they are so cheap. In a day or so I will post the various schematics and PCB board design layouts I have created for the project to date. Sorry for the verbose introduction. If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

So your going 8 wire from your nano control board to power board? Would have been great to see a ten pin connection to make them interchangable for the Poida nano control board design. Cheers Caveman Mark Off grid eastern Melb |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

Its a good idea, if you dont string it out and explain stuff along the way the only readers you get are people that have already been there. I'm confused, no wait... maybe I'm not... |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1236 |

Thanks for the reply Mark. The inverse optocoupler design is not really compatible with the standard FET drives from any existing controller boards without another interface board. If I am going to present a design, I am happy to be responsible and to help others as much as I am able. There is a risk that by trying to interface to existing methodology it might also create issues that I dont really want to contend with. The optocouplers are integral to my power boards and have buffers attached all with very short PCB tracks. Here is a block diagram of the concept: The top unit has 16 FETs in total, the bottom configuration would have 32 FETs in total.  If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1236 |

I dont know a simple way to insert PCB gerbers here so I attached them to a PDF that you will have to look at to see them. 2019-05-13_230646_Gerbers1.pdf If anyone wants the schematics I am happy to post them in a similar fashion, also as a PDF. If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| johnmc Senior Member Joined: 21/01/2011 Location: AustraliaPosts: 282 |

Thanks Mike, For the description and pics of your new Inverter pcbs, will watch with interest as you project evolves . cheers john johnmc |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1236 |

Whoops ! The perils of copy and paste. In the second block diagram both chokes on either the top or bottom pair would both have to be bypassed for 2 choke operation. As shown bypassing one choke on the top and 1 on the bottom would be a disaster.... Thanks John, have sent off the PCBs for manufacture, I hope to get the final OK from them to press the go button tomorrow. If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| tinyt Guru Joined: 12/11/2017 Location: United StatesPosts: 471 |

Will appreciate schematics so I can follow during my limited spare time. Thanks. |

||||

mackoffgrid Guru Joined: 13/03/2017 Location: AustraliaPosts: 460 |

Good one Mike. I look forward to the Scope shots  Cheers Andrew |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1236 |

Im sure there will be plenty of scope shots in due course! Time to post the schematics: First the Power PCB 2019-05-14_230249_4KW_PWR.pdf The Nano controller: 2019-05-14_230332_WG_Nano1.pdf And the Isolated supply for the Power board. 2019-05-14_230431_Isolated_Supply.pdf Now back to PCBWay issue. Previously I had more than one prototype on a panel and cut them out myself. Today they want to treat them as more than 1 type despite being a single file, single origin reference, no routing or V grooving etc just a plain plain old PCB. So I have reluctantly separated them and submitted 2 prototypes. They still have multiples on each PCB but only the one design. Well see how they choke on that .... If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

mackoffgrid Guru Joined: 13/03/2017 Location: AustraliaPosts: 460 |

I see your power module will basically work with Tony's Warpverter as well. RE: Panelization (JLCPCB), After I got stung a little bit on multiple designs on one PCB I found this. JLCPCB Panelization |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

This all looks very good Mike. I originally used pulse transformers for generating the isolated gate driver voltages the same way you are doing. I found it difficult to control the final dc voltage on the isolated side. Overshoot or ringing on the secondaries of the transformer would sometimes produce some worryingly high dc voltages. I managed to fix all that by using full wave rectification, and a suitable zener. It then all ended up working much more predictably. Cheers, Tony. |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Why the 3 paralleled diodes between drain & source? Are the diodes not already inside each mosfet? Klaus |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1236 |

Thanks for the question Klaus and the answer is two fold, yes there are diodes in the FET - the added diodes were an 11th hour inclusion. Please remember this is a first prototype and I am a believer in belts and braces approach. I have made no inclusion for snubbers in my design - it will probably require some and they will be essentially in parallel with the diodes in question so there are holes available to put them in (or legs to solder them to). There is another benefit in not relying on the internal diodes of the FETs to conduct current internally in my opinion. The FETs are already shouldering the bulk of current switching, for every watt dissipated there is a penalty of higher RDS on generating more heat. I wanted to experiment with external diodes such as MUR420 with lower foward voltage drop to minimise heat generation inside the FET by passing current externally to the FET when it is not on & minimising the internal heat. I am also aware that in a final design the MUR420s may be under rated for full load and the TO247 U30D20C or Motorola equivalent MUR3020 will probably be required) This is directly associated also with dead time. The diodes conduct during dead time. Dead-time is essential to ensure no shoot through. Excess dead time I consider an enemy. Efficiency is essentially maintained with excess deadtime but the cost is extra heat in the switching FETs. The sooner the FET is turned on after deadtime the better as then the diode (inside or external to the FET is not conducting & generating heat which is wasting energy. It doesnt actually matter as much that the external diodes may get hot, they become more efficient as they get hotter as the Vf value reduces further. Whilst discussing FETs, one application note I read recently for TO247 (same as the large HY4008) packages had some advice for reducing internal heat in the package. They advised that the Mosfets should be inserted into the PCB up to the shoulder (wider parts of the leg close to the case) and well soldered to generous copper areas as it minimises heat build up of the internal bonding wires. Whilst I really Like the Warp terminal blocks idea and have used it myself, for a serious Inverter I chose to solder directly with short legs - every bit must help. Happy to hear others point of view on any of the above. If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1236 |

I went and fired up the circuit and took some scope shots. The first shot is with no load, the nominal 12V was 18.1V. Loaded with a 220K it became 13.3V, 33K was 12.9V, 470R was 12.02 and 150R 10.9V This shot was loaded with 470R note the leading ringing was gone. Conclusion there is some ringing unloaded at the front edge this has enough energy to raise the voltage by a few volts unloaded. With a 1mA load voltage is less than 13V and with 80mA ~ 11V. I am comfortable that the 2.5mA minimum of the FOD3182 opto will keep it well under control and around 12.5V. The UCC3080 driver seems well suited in this app. If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1236 |

The high current connectors I intend to use for the battery and choke are these They are $66 per 100 or you can get these $9.63 for 5. I am leaning towards the $9.63 solution - just wondering if anyone else is interested in some heavy duty connectors for any of their projects? If I buy 5, I am 1/6 of the way to getting 20 times more. I dont mind funding a quantity buy if there is any interest. For the capacitor board standoffs I will use 6 of these per board I need to buy 100 for ~ $40. If anyone wants some sing out I'll have plenty. Note the first 6 pin larger M5 ones are tinned copper, the 4 pin type are tinned brass rated at 33A. Interesting that the dimensions and material of the 6 pin types have 120A and 100A ratings respectively ? metric amps versus imperial amps ?? If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| tinyt Guru Joined: 12/11/2017 Location: United StatesPosts: 471 |

Are those from this circuit: If so, do you have additional information on the transformer you used? |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1236 |

Yes thats the circuit - I just noticed a typo a couple of posts ago it is a UCC3808 I used not a UCC3080. The UCC3808-2 part I used has been improved and is also available with many choices that should work fine, UCC2808X... and UCC3808X.... Make sure you avoid the UCC38083 & UCC38085 or 2808/3808-1 as they dont start until 12.5V is applied. I used an EP17 core from here The primary I used 18T of 0.2 - 0.25 not critical. The 3 secondaries were 20T of 0.2 -0.25 (or similar) you can even use kynar wire or wire wrap wire they all work fine. The only start finishes that need to be observed are the 3 secondaries. I phased them so the 2 low drivers (1 winding) used one forward phase the other 2 two isolated windings for the high sides both used the other phase (note start dots on tx circuit). I have boards on their way back from JLC if you want 1 or 2 to play with pm me your mailing address and Ill send it to you. If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| tinyt Guru Joined: 12/11/2017 Location: United StatesPosts: 471 |

I am still too busy at work and cannot spend time on this hobby. Thank you very much for the offer. |

||||

| BenandAmber Guru Joined: 16/02/2019 Location: United StatesPosts: 961 |

I also read a article that said legs of mosfet get the hottest And that you should put them down in the bored as close as possible Then I compared the size of the legs of the smaller mosfet and the larger ones The larger mosfet has much larger legs and if the legs are what gets the hottest it would seem to me the larger mosfets are better What do you think Wiseguy and Tinyt Would value your thoughts on this be warned i am good parrot but Dumber than a box of rocks |

||||

| Page 1 of 16 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2025 |