|

|

Forum Index : Electronics : Running Piclog with 48V

| Author | Message | ||||

SparWeb Senior Member Joined: 17/04/2008 Location: CanadaPosts: 196 |

My neighbour installed a windmill recently, but it is not performing well. He purchased a "turn-key" kit from a local company, and the equipment they installed is a mix of local structural materials, Sanyo solar panels, Xantrex XW power distribution, and chinese windmill components. The solar has been running well for nearly a year but he hasn't seen much from the windmill yet. Apart from fears that there is an electric or electronic brake still turned on, we're not sure the blade pitch is set right, either. The installation company is trying to help, but my (indirect) impression is that they are trying to fix things willy-nilly without spending the time to be present, to witness and understand the problems themselves. The operating instructions that they left my neighbour are next to useless. One of the things I want to do to help him is to hook up my PicLog into his system to take measurements of what's actually happening. I would bring over my anemometer and put the Piclog program on his laptop. His system is based on 48v, and mine is only 24v. The Piclog plans only cover 12v and 24v operations. Has anyone adapted a Piclog to run on 48 Volts? Are there an pitfalls or dangers to doing this? I suppose the 7805 voltage regulator can't handle input voltages that go up to 60V, so I could just use an AC plug wall-wart to give it 12VDC. On the input voltage and RPM detection side, will the circuits as shown in the diagrams be safe? The voltage detector needs the 22k resistor @ 12V, a 39k resistor at 24V, so that could be increased to 68k, or would a voltage divider be better? Detecting RPM, I could increase the 10k resistor to 22k. Any other thoughts or suggestions? BTW, recent monitoring of my windmill with Piclog shows that the performance of my windmill is CHANGING. That's weird. I haven't gotten to the bottom of it yet. Steven T. Fahey |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi sparweb, The logger interface that I built for Phillm, based on the picaxe08M and compatible with Gizmos PicLog logging application works on 48V. I did not use the 7805, but used a separate 5VDC for the micro. This could be from a plugpac, or from a 48V-5V DC-DC converter. There were some changes to the rpm and windspeed sensors and scaling resistors for voltage. I think Phills is working well now, with some changes to the picaxe code to prevent negative numbers on the current sensor with the Allegro chip. Gordon. become more energy aware |

||||

| BjBlaster Regular Member Joined: 04/04/2008 Location: AustraliaPosts: 55 |

I found this too, but what code change did you use to stop the neg numbers? I was just subtracting 125 to get zero ref but found it floats a bit.... Check out my projects here in: Bj's Shed |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi BJ, The mod for Phill was quite simple. Phill used the 10 bit ADC read, and the rezo reading was 507. This only works with readings going one way. In the picaxe code, just compare the AMP reading with the known zero reading, and if it is less, then just make the value equal the zero reading. This is only 3 lines of code. If the reading is greater than the zero reading, then just leave it. This will stop the accumulation of negatives when there is no current. The same type of code could also be added to the VB application. Gordon. become more energy aware |

||||

| BjBlaster Regular Member Joined: 04/04/2008 Location: AustraliaPosts: 55 |

Thanks Gordon, I was just checking that there wasn't something like "gee why didn't I think of that?" type of code... Cheers Bj Check out my projects here in: Bj's Shed |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

The trouble with subtraction and integer numbers that end up close to zero is that 126-127 does not equal -1, but equals 255. Gordon. become more energy aware |

||||

SparWeb Senior Member Joined: 17/04/2008 Location: CanadaPosts: 196 |

Thanks Gordon! I discovered that my neighbour's inverter and distribution panel installation does not include an AC outlet! Slap on the forehead, guys!

Oh well I'll find an extension cord for the little AC/DC block. My Piclog is only set up for a shunt. I may start without one, because I shouldn't be adding components to his circuits without knowing more about what I'm doing. For now the RPM correlated with wind speed will indicate clearly enough if something is wrong. I'm pretty bummed out today because I had an accident with my tower. It has completely destroyed my windmill. On the bright side, my piclog is now free to be used for more philanthropic purposes! I posted details of the accident on fieldlines. No point depressing all you guys downunder, too. You have enough to be depresesed about, with winter coming soon.  Steven T. Fahey |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

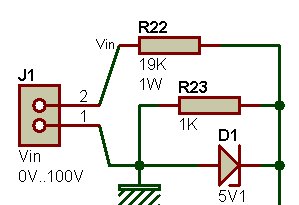

I found here (I found it first on mikroElektronika forums ) a digital voltmeter for 0 - 100V range. See the divider:

100V = 5V = 1023 digital. If I'm right, the resolution is 0.1V rounded... Of course, the software must be tuned accordingly. And can be used to any setup (12V - 24V - 48V) without (hardware) change. Note: high precision resistors must be used. If you can't find 19k resistor, you can use two, 18k + 1k resistors PicLog can be alimented from a 12V battery from your battery bank and measurement pin can be connected normally Any thoughts? Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi vasi, I don't think the problem was in measuring 48V, but operation of the micro from a 48V supply. Gordon. become more energy aware |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Hi Gordon, I'm not good at English and I was fooled by this: Anyway, I think that divider can be a good "upgrade" to our controllers/loggers... I will try it. Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

SparWeb Senior Member Joined: 17/04/2008 Location: CanadaPosts: 196 |

Vasi, Sorry about the misunderstanding. As I re-read it myself, it's obvious I was writing "to Gizmo" and not to the general audience. Without the diagrams beside you, you wouldn't know what I was talking about at all. Steven T. Fahey |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |