|

|

Forum Index : Electronics : Using old circuit breakers as 3 phase swi

| Author | Message | ||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

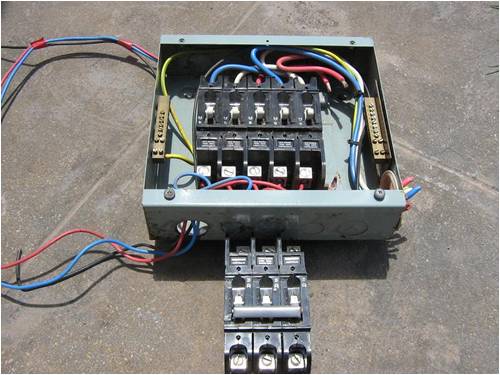

Using old circuit breakers as 3 phase switches for windmills. These are cheap switches and have heavy contacts to handle the current, but they also have a down side of incorporating a circuit breaker. A circuit breaker can be a dangerous thing in a windmill circuit as if it trips it can leave the mill free wheeling without any load, causing a runaway. On closer internal inspection it is very easy to disable the circuit breaker inside these switches to allow them to function as a switch only. The other thing I found from disassembling several breakers is the contacts are all the same regardless of the rated amperage stamped on the breaker and the amps only relates to the circuit breaker that we donít want to use anyway. In short..... a 10 amp rated breaker has the same contacts as a 80 amp breaker, so any will work well for a mill. The other nice thing with these switches is they have large wire terminals and are all able to be mounted neatly on a din rail within an enclosure. My lot costed $10.00 with the enclosure included. (several not shown)

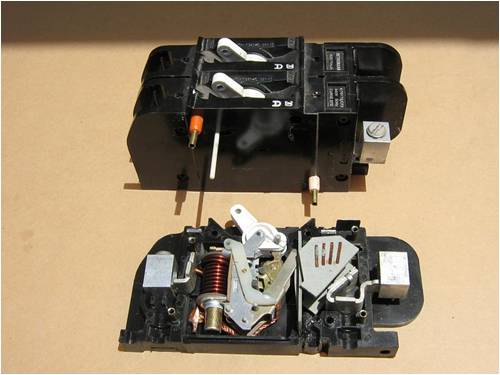

This is how you disable the circuit breakers inside. First you need to drill the head off one end of the 2 brass rivets holding the block together and remove the pin ganging the 3 switch levers together. (that is if you have a 3 phase circuit breaker module) Separate each of the 3 breakers so they are 3 single breakers. Drill the heads off the 4 brass rivets holding each of the 2 switch halves together. Press the rivets out slightly and then drill the bakelite housing a fraction deeper to allow for the rivet to be reused and re-riveted again. Part the 2 halves of the switch gently.

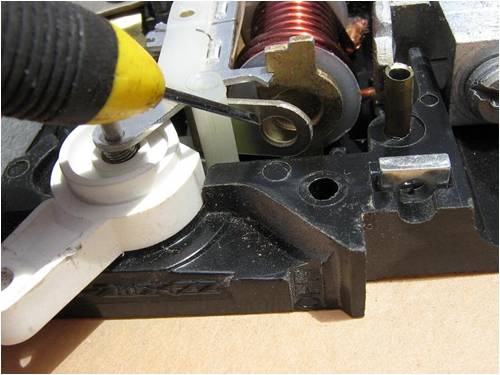

Move the switch to the closed position and then press down on the plate over the end of the coil, while watching the trip mechanism within the switch. Magnet plate over coil.

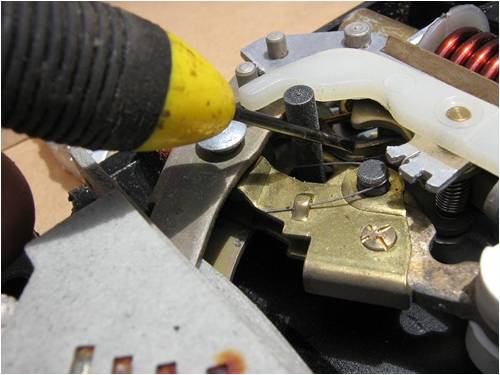

Trip Mechanism lever in switch

This is what the mechanism looks like, and itís the little curved lever at the bottom than needs to be bent back.

With a screwdriver gently bend the mechanism back within the switch without removing it, then closed the switch again and try pressing down the plate over the coil, this time the switch should stay latched and not trip as it did previous Modification done and now just need to assemble the switch again and fix the rivets. I placed a small section of rod in the vice to sit the rivet head onto, and used a centre punch to gently expand the end of the rivet the head was drill off. 1-2 light taps with a hammer and rivet was fixed without cracking the housing. All up it took about 5 minutes to do a full gang of 3 switches from start to finish. Pete. Sometimes it just works |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5024 |

Good post Pete I've wondered if those circuit breakers would work for switching a windmill. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

So Pete, with your mod does the coil plate still move if there was an overload? Would it not be simpler to jam it up, preventing that movement? Says he who does not have a circuit breaker handy to check that out  Klaus |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

[quote]So Pete, with your mod does the coil plate still move if there was an overload? [/quote] Yes [quote]Would it not be simpler to jam it up, preventing that movement? [/quote] No. Hi Tinker, To bend the tag is sooooooo very easy, and it dont effect the way the switch operates. I tried removing the whole lever but it then needs other changes to allow the switch to function correctly. Looked at chopping the wire off the coil and soldering it direct to the output to bypass the coil, but a pain to solder onto a heavy copper terminal. All said and done a little bend in the lever done the trick and is so quick and easy to do. Pete. Sometimes it just works |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Pete Good recycling tip and these breakers are generally a lot higher capacity than some of the switches I have seen used. All the best Bob Foolin Around |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Yes, but one has to remember that the contacts are designed for AC. Usually DC contacts, especially the higher current type, have a different contact material and switching movement to prevent wear & contact arcing. I guess time will tell how much DC they can handle if anybody is keen enough to switch 80A or so

Oops, just noticed that Downwind was using them for AC. My comment obviously is for those who might try then on DC. Klaus |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Tinker Yep you got it mate just for AC they are OK, I have tried them on DC but the arcing tends to blow out the contact even with a condenser across the contacts, for heavy DC a solinoid with heavy copper contacts is the best, I have some contacts out of a 110 DC system rated at 200 amps, the contactors are a block of copper 1 inch square by half inch thick, really serious devices. All the best Bob Foolin Around |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Tinker i think it good you point out some possiable negatives with these as it creates a discussion and a heads up on things that might get overlooked. Yes i did intend on using them for AC, but think they would work fine with DC as an isolator switch....BUT one would want to use some care as you and Bob has pointed out, and not engage or disengage the contacts under heavy load so as to cause excessive arcing. Once the switch contacts are made they would be heavy enough to supply the current for a DC operation. In many cases we only need a switch on the DC side for emergency or as a system isolator and these would serve that purpose well. I wanted them as a isolator on the AC and as a shorting switch on the AC, so would need two blocks of 3 switches. In reality i dont really need a 3 phase isolator, but for some reason feel it could be worth adding. I like the idea of all switches cabinet mounted in a single enclosure, where things can be neatly labelled as it would be for any mains control panel. The use of these switches might be an overkill but allows for a neat setup for a dirt cheap price. Pete. Sometimes it just works |

||||

| mid north Matt Regular Member Joined: 06/01/2011 Location: AustraliaPosts: 58 |

for a very high current switch why not use a car/truck starter motor solinoid,the part to hold in the contacts could be a thread rod/spring with a handle and doesnt matter if the pullin coil is shot Pt Wakefield Matt |

||||

| Alasdair Regular Member Joined: 12/01/2011 Location: AustraliaPosts: 62 |

Hi Pete Great idea, and good safety improvement, especially when things start smoking, and your only option is wirecutters or a screwdriver, which as we all know will disappear if you need them urgently. Another good feature of mains breakers is that the mechanism is geared to accelerate the contacts apart really quickly and slam them together at switch on, hence the heavy spring and clunky nature of the toggle. This would be beneficial for dc, I think you'd get lots of cycles before any contact breakdown happened. I found a box of clipsal 80A isolator switches at tipshop which I use with DC, I only run 20 amps through them maximum and the voltage drop across the switch is about 1mV, or next to nothing. I just flick them quick and give them no time to burn pits. I also made a rail cannon many years ago which fired a steel pellet that was accelerated my a big magnetic impulse. It was energised by a huge bank of capacitors charged up to about 400 volts and dumped across a twenty turn coil of 2mm wire. I tried all kinds of switches and triacs but none could stand the umpteen thousand amp burst, except a big old Bakelite isolator I found in my fathers shed. It took it again and again with a huge crack when it closed. I never worked out how many joules were passed but 5000 mtd at 400 volts dc into about .001 ohms is pretty extreme. All in the name of science of course, I was only fifteen. Regards Alasdair. Amc-elec |

||||