|

|

Forum Index : Electronics : Back -EMF braking - How is it done?

| Author | Message | ||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

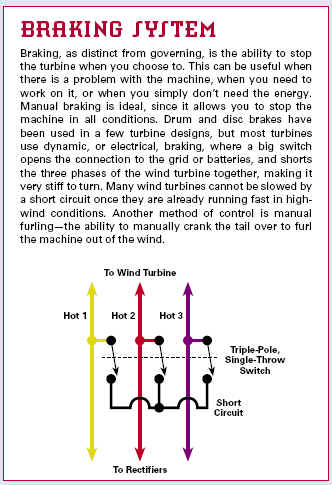

Hi, Have Google-searched Fieldline, no hit. Some smaller mills attached to solar panels, like on fire lookout stations (Mount Frankland near Denmark - SW of WA) do not feature furling but "back emf-braking" is done to stop overspeeding. Does anyone know how that is done?? Rather than shortening out all three phases with the danger of magic black smoke escaping, what is being done? Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

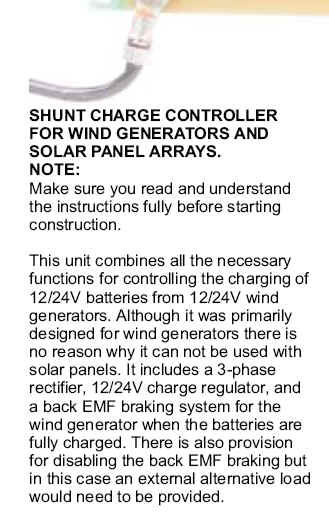

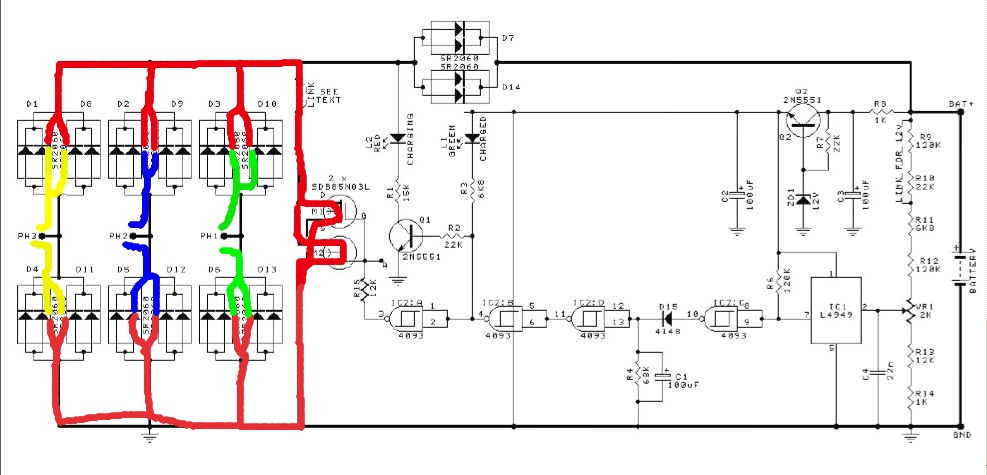

Hi Dom, You've already got it in one. It's shorting out the 3 phases. For example: Oatley Electronics _ Kit K241

Good heavy wiring or fire extinguisher needed.  was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5024 |

I could short out the F&P windmills at full speed in high winds with no damage. If the wind was really blowing, the windmill would keep on going even with all phases shorted, but a check later showed no heat damage to the stator. Made a hell of a big spark though, a few henry's in those F&P stators. It would have got hot, for sure, but exposed windings on steel laminations in the cool air flow would have keep temps under control. The problem does show up in those dual stator home made alternators where the windings are embedded in epoxy. There is no way for the heat to get out, so they cook themselves. So long as you can pass cool air through the coils, or over the laminations ( via the cooling fins in induction motor conversion ), the alternator should survive full shorts without damage. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Hello Guys,, I have installed a big 3 phase breaker beside my control box . The mill 3 phases come in through this switch and before the rectifier bank. It works perfectly,but wait till the mill slows,by keeping an eye on the Amp meter, then switch in the dead short, a piece of bussbar connecting the 3 seperate breakers . No damage ,so far. I've wsitched it on at full speed,but as Glenn says ,the mill ignores it until there is a drop in rpm. Great for lowering and raising the mill also ,,you don't want things happening while you are concentrating on the rigging ,winch,and final resting of the 55 foot piece of heavy steel. PS-- you know how the tail is in the furled position when raising the tower ? . well to stop it crashing back to the correct position when nearly vertical, I bolted a rubber engine mount as a 'shock-absorber" and now the tail swings back and comes to rest smoothly.. Having fun, Bruce Bushboy |

||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Thanks for the info. Good idea to have it for the lowering/raising! Did not think of that. Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

| herbnz Senior Member Joined: 18/02/2007 Location: New ZealandPosts: 258 |

Hi The F&p units have a characteristic that will always limit the current seems to be well inside the level that will damage windings. The reason for this is the ampere-turns of the statorin a generater oppose the field from the rotor (lenz's law ) so flux is reduced to very low value as current flow increases. Any extra torque applied after this point will increase speed and with no flux there will be no increased current flow to oppose it we are in a run away situation. shorting windings can not help until we get back to the situation where we again have the flux back from the permanent magnets. The units that will work with dynamic braking do not operate to the level that they nearly kill the flux in the coils. So much more current can be produced with a short than their normal operating current this opposes the applied torque and brakes the unit.Maybe we should not be operating at the current levels we do. I feel that F&P units on windmills should have some form furling because of this. Also Glenn the sparking you are getting is not I feel due to the Inductance but the high freguency bad on the DC side the ripple with three phase rectifiers can be up to 2Khz I have tried to switch outputs with relays under load not many can handle it you get flash over. Same as output from Inverter welders. Herb |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

Just a little comment here.... Yes, common thinking is "3 phase circuit, need 3-pole switch". I did my brake with a heavy duty *DOUBLE POLE* switch which was WAY easier to get and LOTS cheaper. If you think about it logically, you don't need 3 poles. Join one end of BOTH poles of your switch together with heavy wire and run that to phase 'A'. Run phase 'B' and 'C' to the other ends of the switch. When the switch is open, all 3 phases are unaffected. When the DOUBLE POLE switch is closed, all 3 phases are shorted together. |

||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Once again, many thanks. It is also getting cheaper by the minute! Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

marcwolf Senior Member Joined: 08/06/2009 Location: AustraliaPosts: 119 |

Just an idea on this.. If one was running a dual stator F&P system and one was to short out each stator that would essentially provide double the drag and hopefully reduce the spin speed. Any comments? Dave Coding Coding Coding.. Keep those keyboards coding.. RAW CODE!!!!! |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

The only way of stopping a F&P Dual or single in full flight is with a mechanical brake , this is a problem inherrant with F&P mills and is why furling is of upmost importance to have correct . With my mill it reaches full power 750w at arround 500rpm and the rpms have regulary hit 750rpm with little extra output for the increased rpm as the stator becomes saturated and the torque curve falls away , basicly you have a mill out of controll. This is why I have decided to now move to the Oz Ax Fx , when you throw the switch it stops in any wind ! As well as being superior in performance .. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

deleted by me Luck favours the well prepared |

||||