|

|

Forum Index : Microcontroller and PC projects : 3D Printers....

| Page 1 of 2 |

|||||

| Author | Message | ||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9874 |

This thread is a diversion from the HC12 programmer thing, where 3D printers are being discussed. I am looking at several different ones, as they are quite affordable now. This one is my current favourite, as it comes fully assembled, free DHL shipping, and is an extremely nice looking unit. Those big open-frame 3D printers look ugly(to me). This unit also has 100% positive feedback from people who have bought it. What do other members here who have 3D printers use? Smoke makes things work. When the smoke gets out, it stops! |

||||

| disco4now Guru Joined: 18/12/2014 Location: AustraliaPosts: 1091 |

Hi Grogs, I have one close to this from GeeeTech. Mine was a ProC model which has two print heads. Never used the second one so not really necessary. It came in bits and I paid about double what it is now. Putting it together was half the fun and then learning some of the tricks of printing. Getting the print to stick to the bed took a bit of experimenting, but a spray of circuit board laquer has proved very effective. Print area is 200mm*200mm*200mm . GeeeTech 3D Printer The new style you are looking at looks nice and is already together. The good thing I see is the Bowen style print head. (The stepper motor is mounted on the head but pushes the filament via a tube). This means the head is lighter and can be pushed around with less inertia. One comment says the print bed is not heated. This may be an issue as a heated bed helps the thing you are printing stick. With the laquer I can't get the print off the bed until it cools down, so really sticks well. That is on a glass bed. Yours has an aluminum bed so I am not sure whether they really need to be heated or not. The software you have is pretty much the same and seems common to all. The print area of 150*150*150 will do a bezel for a 5" screen but not sure about a 7", but would have done all the things I have done so far. The aluminum from I think is a good thing. You should get one. You will find many uses. The first being to print a filament spool holder for the 3D printer. We all do that straight after we print a rabbit and a small boat. F4 H7FotSF4xGT |

||||

| Bizzie Senior Member Joined: 06/07/2014 Location: AustraliaPosts: 192 |

My engineering background makes me prefer the "big open-frame" ones as there is support at both ends of the respective axises. That arm would easily sag as the head passes to the outer end. Wear would also be great as I assume that arm will be an aluminium extrusion. Someone else may like to comment on this but my reading suggests that a heated platform is necessary for larger objects (I do not own a 3D printer). disco4now's link gets my vote so far. Rob White |

||||

| MikeO Senior Member Joined: 11/09/2011 Location: AustraliaPosts: 275 |

GeeeTech I3 as well. You have to be prepared to spend some time learning I think with any cheap 3D printer. Edit: Agree , Just seen Bizzie post, The one I have has proved to be very rigid (although I was skeptical initially re acrylic frame) however this was not a problem. i also tied the frame down to a 20mm ply base.  Codenquilts |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5168 |

I built a delta 3d printer about 18 months ago, and used it once  Building it and tuning it to get good prints was fun. But it also taught me just how slow these things are. Designing a part in the software of choice is half the battle, and can take just as long as it does to print it. Then there are the issues with it not sticking to the table, deformation, and a print suddenly going pear shaped after a couple of hours, big time waste. But I come from a CNC background, where I used 5kW laser cutters and industrial CNC routers. These machines make a part in seconds. In my workshop I have a CNC router, lathe, mill, MIG, etc. So I've been spoilt, and I'm impatient and lazy. If I need a part, I could spend 2 hours 3D printing it, or 5 minutes in the shed routing it from a block of MDF or HDPE. I guess thats why I dont use my 3D printer. I'm not saying not to get one, they are fun, but if you have a CNC router, it will do most of the jobs a 3D printer can in a fraction of the time. I guess it also depends on the parts you want to make. Just something to consider. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Andrew_G Guru Joined: 18/10/2016 Location: AustraliaPosts: 874 |

Hi Grogs, watching with great interest! How long before PCB printing becomes affordable for DIY shedders? Andrew |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9874 |

Very interesting replies - thanks chums.  I am now looking much closer at the Geeetech one disco linked us to - they are a little cheaper too.  The Geeetech one has a heated bed, which should help keep the item stuck down while printing. I had not noticed that the other one I linked to at the start of this thread, does not appear to have one.  One thing I would like to do is bezels for 5" and 7"(160mm or so) LCD's as mentioned by disco, so the Geeetech is now the front-runner.  Any other comments still welcome. Smoke makes things work. When the smoke gets out, it stops! |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

A heated bed and not having an enclosed printing area is a recipe for warped prints. Only PLA will work with this. Another thing to be aware of is the software that is used. If your printer supports something like Cura then you will have a lot less stress then when using others. I hav two Ultimaker printers, for more then 5 years now. Perfect machines with little trouble. The newer ones are even better. The bowden tube works but i would prefer a stepper on the head itself as you will be able to use more types of filament. The flexible filaments for instance are very interesting but impossible to use with a bowden tube system. Basically a bowden lowers the usability of the printer. For big prints i prefer printing it in smaller parts that can be glued together. Failure rate goes down and if you have more then one printer, printing time is halved. Nowadays having more then one is doable as the prices are pretty low. However once you got yourself a lasercutter or CNC, thenthe 3d printer is going to collect dust as both both the lasercutter and CNC are more suited for small production work. Microblocks. Build with logic. |

||||

| MikeO Senior Member Joined: 11/09/2011 Location: AustraliaPosts: 275 |

I have a small CNC machine as well as the 3D printer, I do bezels (in acrylic) on the CNC and the enclosures on the 3D printer. Mike Codenquilts |

||||

Chopperp Guru Joined: 03/01/2018 Location: AustraliaPosts: 1116 |

I bought a Cocoon from Aldi a number of years ago. Looks a bit like the GEEETech. Like Gizmo said, they take ages to print anything of reasonable size and they have to be continuously monitored as things go wrong. A lot can go wrong during a 10hr print. Nothing worse than coming back to it after an hour or so & find the print-head in mid air with a cm or 2 gap underneath it. The biggest problem I have with mine is getting the movable base (platen or whatever) level ( X & Y axis) with the print-head. It always needs adjusting. The first layer is the critical one. You have to watch it print that. (Must try circuit board lacquer on the base). Mine gets used in bursts with a long break between but I have made some useful stuff with it. May fire mine up again soon. MikeO's piccie gave me an idea for something.  Heaps of stuff on the net to glean from. ChopperP |

||||

| Azure Guru Joined: 09/11/2017 Location: AustraliaPosts: 446 |

I don't have one yet as I said earlier. I did a fair bit of research but could not make my mind up at the time. From what I learnt while researching options, I agree with the other comments you need a heated bed, even if you have to retrofit one. Rigid frame is a must for quality printing. A lot of the other parts rails/bearings/printhead(s) come down to quality vs price so you have to choose what you expect for the price you are willing to pay. Good luck with whatever you choose. I will be reading with interest to see if it convinces me to bite the bullet. |

||||

| CaptainBoing Guru Joined: 07/09/2016 Location: United KingdomPosts: 2171 |

I have a Cetus 3d Mk2. Small amount of assembly, has Wifi and USB, works un-tethered and worked well with the default setup. https://www.youtube.com/watch?v=mnTiSZJdN34 Gizmo is right, they can take a while which is why you need a printer that is just going to work so you can leave it to do its thing while you are work. I only use PLA, which needs to be cooled quickly to prevent warping and no heated bed. Print everything with a raft and I had no troubles at all. A few teething problems (Leveling the bed is a bit involved first time) but since then I print pretty much without issues. The print area is smaller than others, being only about 7"x7"x7" but you can get an extended version which will take Z to about 12". 7x7x7 cube isn't an issue for me as the biggest thing I have printed so far (Telescopic sight camera mount) was just under 6" I print in grey or black PLA and if the finish is important, I use spray filler and 800 grit wet and dry then paint in the desired colour with an acrylic paint for plastics. Very nice results. PLA is workable, glue-able, paint-able and bio-degradable so if my waste ends up in landfill, no problem. Smells nice (if at all) when printing... bit like popcorn. PLA can be brittle if the infill is miserly but very strong normally - solid PLA blocks can be weight-bearing and take screws that need a moderate amount of force. Great for custom electronics enclosures... currently printing a MicroMite "idiot light" mimic for a Harley Davidson FXD. Never tried ABS, too many headaches - heated bed, slow cooling, warping, smell, specialist recycling (applies to ABS in general) god vid here comparing ABS and PLA prints with varying infil https://www.youtube.com/watch?v=bmgSojocJ3c my 2p |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9874 |

Sounds like 3D printing is very time consuming. I thought it was RELATIVELY quick. What are some example times? Smoke makes things work. When the smoke gets out, it stops! |

||||

| twofingers Guru Joined: 02/06/2014 Location: GermanyPosts: 1720 |

Good topic! I bought my Anycubic I3 Mega half a year ago for 250 € and I am satisfied. I especially like the UltraBase (special glass plate) and the stable frame. Cons: the loud fans (I will replace). I print my enclosure for the Mites with PLA. It is important to find the right filament (~ 17 € per kg). I think the print area - for my purposes - should have at least 200x200mm. Enclosure for the Duinomite Mini:  Enclosure for Micks BP170 and a CP2102  I design my 3D models with Tinkercad (online). Slicer: Cura. Michael causality ≠correlation ≠coincidence |

||||

| PicFan Senior Member Joined: 18/03/2014 Location: AustriaPosts: 133 |

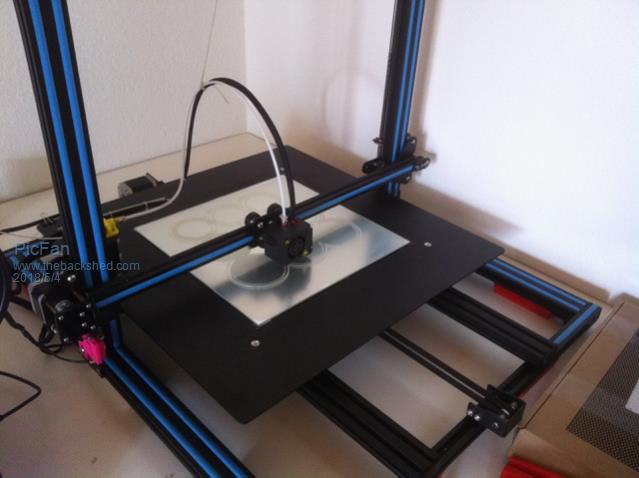

This is my printer park. If you want a plug and play device, there is only the Zortrax M200 for me. If your parts are larger than 200x200mm then I would like to give you the Creality CR-10S5, but you have to deal with that a bit already. Then there is the question which material for which temperature ranges you would like to use? Greetings from Tyrol! Wolfgang  The "BIG" CR-10 (500x500x500mm, Printspace)  |

||||

| MikeO Senior Member Joined: 11/09/2011 Location: AustraliaPosts: 275 |

You have fiddle and experiment a bit IMHO BUT the results when you get to know your equipment and software can be quite rewarding. I also print with PLA which costs ~ AUD35 1kg(Araurum ) Its worth buying good quality. Selection of Projects: The longest was the Stevenson Shield ~ 18hrs, typicaly small parts and enclosures would be say 3 - 7 hrs. I run my printer stand alone (it has internal SD card) recently I put it on my UPS , as ther is nothing more frustrating where a brownout ruins a print. Caravan Meter enclosure (MX170 2.4"LCD)  Battery sensor mount , Pi Zero enclosure, Stevenson Shield for Weather Sensors  I use TinkerCad for design and KISSlicer here Codenquilts |

||||

| MisterOz Newbie Joined: 03/03/2018 Location: United StatesPosts: 1 |

I'm running a CR-10 with some mods and a Prusa MK3 here. Actually assembling the MK3 now as I post this. I run an Octopi setup as both printers are in the basement. |

||||

| isochronic Guru Joined: 21/01/2012 Location: AustraliaPosts: 689 |

Can a layer of the material be used as pcb etch-resist layer ? [assuming it can be dissolved away with solvent etc] |

||||

| pjmart Newbie Joined: 13/11/2016 Location: AustraliaPosts: 9 |

Great Topic. Five months ago I bought the cheapest 3D printer kit (CTC Prusa I3 Pro B, 200x200x180mm print) as a means of getting some 3D experience before lashing out and spending up on the more expensive/capable/quality units. It has been a steep learning curve but but am now at a point where I would not bother with the next step until I needed to print something bigger. I current print using both ABS and PLA filament, the latter has a relatively low softening temperature (around 60'C) and I suspect could give problems with enclosures located in hot areas (car interiors, direct sunlight through windows, etc) What I learned along the way has already been pointed out in earlier comments with one exception. I initially had many problems with the filament getting stuck/not feeding through the extruder resulting in partial prints, etc. It is not fun to have to watch the printer for the full duration of a print (typically 2 to 12 hrs for small to medium sizes) just in case. The simple solution is to add a couple of drops of Canola Oil to the filament just before it enters the print head which appears to stop the filament sticking to the internal PTFE tube above the extruder nozzle. Only a couple of drops each day are required. I have not had a failure/jamb up since and regularly run my prints overnight unsupervised. The printer you are favouring is equivalent to my kit and will do a good job. The one modification which will greatly improve quality of print is to free up the Z (vertical) screw bearing blocks. You can see the mods made by MikeO in his first photo of his printer (the ORANGE plastic half moon shaped blocks) with details available on THINGIVERSE web site. I can supply further info if required. |

||||

| ryanm Senior Member Joined: 25/09/2015 Location: AustraliaPosts: 203 |

Don't know if you're still watching this one Grogster, but I just got a Geeetech i3 based off the recommendations in this thread. Dynamite little unit, super easy to get going with the PLA that came with it. Swapped over to PET today (stuff coke bottles are made from.) Had a bit of trouble getting it worked out, but now I'm making parts that can take a hammer blow and laugh it off. |

||||

| Page 1 of 2 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |