|

|

Forum Index : Microcontroller and PC projects : Ingress Protection - Remote MM Station

| Page 1 of 2 |

|||||

| Author | Message | ||||

| Andrew_G Guru Joined: 18/10/2016 Location: AustraliaPosts: 874 |

Good morning all, I think I have found the source of my intermittent problem with my MM170-based weather station remote - it would either just stop working or re-boot continuously. I'm using an IP65 enclosure and there is never any sign of moisture but just now I pushed the MM170 chip into its socket (a wipe type) and it burst into life (the chip was already fully in but the slight movement would have re-set any "corrosion"). Presumably there is some unseen "corrosion" going on (IP65 won't stop humidity getting in - I know that because it has a DHT22 inside it). My question is - what are the options for a longer-term solution?: - a squirt of WD40 - a better enclosure - soldering the MM to the board (vero) - using a turned socket rather then a wipe one - using a BigMik or similar module with the IC soldered in What do you do? (If I can't resolve this I'll have to reconfigure the remote to place the MM "indoors" and run longer cables from the sensors to it). Thanks, Andrew (with the weather station on my bench it is now raining for the first time in months - Melbourne) |

||||

TassyJim Guru Joined: 07/08/2011 Location: AustraliaPosts: 6452 |

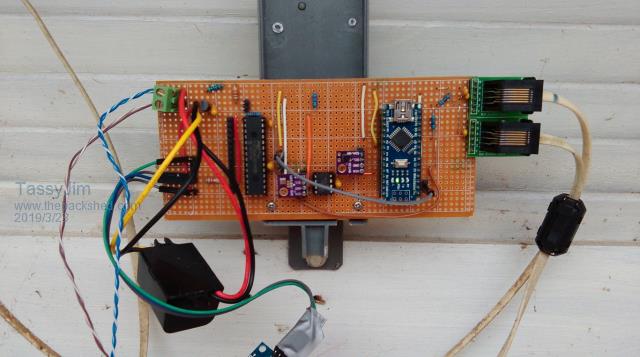

Soldering and a spray of lacquer should help. Even soldering the Vcap directly onto the chip legs should help a lot. I have a similar dilemma. My first rebuild of my weather station used a NucleoL4 squeezed into the original fine offset weather station case.  I had a number of problems with that configuration so I went back to a MX170. The module on the right is an Arduino (WeatherDuino) which shares the wind and rain sensors.  Both the above were housed in a Stevenson screen. I have had other systems in free air for many years without issue so time will tell how this one goes. Rain due on 1 hour here! Jim VK7JH MMedit |

||||

| Andrew_G Guru Joined: 18/10/2016 Location: AustraliaPosts: 874 |

Thanks Jim - I knew I was not alone. Andrew (Our rain is just thunderstorms whereas yours is a front I suspect, we are due to get it later on. All very confused with Trevor and Veronica.) |

||||

| robert.rozee Guru Joined: 31/12/2012 Location: New ZealandPosts: 2492 |

i'd definitely go for machined-pin sockets, along with applying silicon grease to the mx170 socket and any other connectors. silicon grease will 'creep' along the metal pins and contacts forming a continuous barrier to moisture while not interfering with metal-to-metal contact. it is also a good idea to have a small downwards facing vent hold in any fully sealed enclosure. this avoids any difference in pressure between inside and outside. i have seen unvented enclosures pump water from outside to inside slowly over time as they heat up during the day and cool down at night. in one instance, a sealed radio was pumping water up the aerial cable - after serveral months in service there was 1/4 of an inch of water inside which completely baffled the other engineers! if you are really serious, type goretex vent into google. cheers, rob :-) |

||||

| BrianP Senior Member Joined: 30/03/2017 Location: AustraliaPosts: 292 |

It might be worth as an extra arrow to the bow to add some silica gel sachets (as many as can fit) to the interior. Not a permanent solution by any means, but this will slow down the moisture problem dramatically. I can't think of a "permanent" solution (except some form of heater - not practical), but what about a moisture indicating substance (blue-pink) visible behind a window - this would at least give you a visual check. Although your DHT22 would tell you this anyway. The WD40 idea is a good one, although my preference is the INOX product - much better & longer lasting. I've had really good outcomes using INOX, both with corrosion prevention & fan bearings lubrication. Lasts heaps longer than WD40. I'm a bit surprised at the socket issue though - perhaps a dissimilar metals contact problem - only fixed by the soldering-in option. Just my 2c worth...  B |

||||

| PeterB Guru Joined: 05/02/2015 Location: AustraliaPosts: 667 |

G'Day All In my experience solder is the only way. Metal to metal contact will eventually corrode and fail although machined pin contacts are good. To add to rob's experience, we have had a plastic bag enclosing a hot stepper motor take up enough water to solve South Australia's water problem. I also have a theory that a microscopic crack in a PCB track will fail as corrosion builds up and then start to work as soon as the board is moved and the thin film of corrosion is cleared. My mate's Astor portable radio complete with ge transistors was still working 50 years later hanging on a nail in their laundry. The only replacement was the loop stick which broke every time it fell off the wheat bags. I feel better now I've got that off my chest.  Peter |

||||

| Andrew_G Guru Joined: 18/10/2016 Location: AustraliaPosts: 874 |

Thanks to you all. I've soldered the Vcap to the pins and put it back outside to see how it goes. Next step is machined pins and silicon grease, then after that a complete new version using an Explore 28. I'm still thinking how best to vent it because I can see how it would pump in moisture and, as it is up a pole in the sun, I suspect the temperature and humidity readings are sus as well. Thanks again for you help. Andrew |

||||

| PeterB Guru Joined: 05/02/2015 Location: AustraliaPosts: 667 |

In my opinion, it is almost impossible to measure temp. "up a pole". The best place I found was under a small, stand mounted, water tank. Out of direct sun light and open to free air movement. It agreed very well with formal temps. There is a method which puts the sensor inside a metal tube which is heated / cooled to be the same temp. as the sensor ?????????. I would like to measure rainfall, if it ever happens. Peter |

||||

| robert.rozee Guru Joined: 31/12/2012 Location: New ZealandPosts: 2492 |

i've always found soldering an smd component directly between two pins of an IC a tad troubling, particularly when the IC is socketed; it is so easy for a small movement of the pins to fracture the component, something chip ceramic capacitors are particularly susceptible to. btw, one of the first things i purchased when i starting tinkering with micromites was a small bag of 10uf leaded chip ceramic capacitors, each one physically just a fraction larger than a 0.1uf decoupling capacitor. cheers, rob :-) |

||||

| Phil23 Guru Joined: 27/03/2016 Location: AustraliaPosts: 1667 |

Ditto the above. First thing I noticed when I receive my Davis weather station a few years back was that all the 6P6C RJ11 sockets in the transmitter were pump full of dielectric grease. |

||||

| Volhout Guru Joined: 05/03/2018 Location: NetherlandsPosts: 5688 |

1/ solder everything (no sockets) also solder conneting wires. 2/ except for the DHT22, paint everything with an oil based paint. Transparant is neat, but any color you have laying around will do (pink ?). Wait for the paint to dry, and give it a second layer. I do this with all electronics that go into RC racingboats. And these get wet inside. cannot avoid. Succes PicomiteVGA PETSCII ROBOTS |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2979 |

GDay Andrew, I would use a MACHINE PIN socket any way (I never use wiper ones unless I need them to accept square pin headers) Have a look at my Repertoire I am more than happy to send you any of my boards to assist you.. I suggest most likely MuP2 or MuP3 with a MuP-Proto PCB. (not listed in my list but I can provide details for you) Are you the Andrew from the 3 Letter suburb Name? If not PM me your address/Post box details. Kind Regards, Mick EDIT. I am a bit concerned about using WD40... Surely that is conductive to some degree? Mik Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

| Andrew_G Guru Joined: 18/10/2016 Location: AustraliaPosts: 874 |

Many thanks again - good suggestions still rolling in. The beast up the pole is still working and your comments are helping me "design" the next version (and any other devices in the weather) - all very helpful for a non-electronics engineer. Re the pumping effect, and to better enable humidity to be measured, is there any point in having a short tube pointing downwards at the bottom of the enclosure filled with stainless steel wool (to stop the ants)? or is there a real item? Bigmik, yes it is ME (and there can't be that many 3 letter suburbs - I do like your attempt at protecting my privacy). Cheers, Andrew |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2979 |

GDay Andrew, Which flavour PCB best suits your project? I will pop one in the mail for you. Kind Regards, Mick Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

| Andrew_G Guru Joined: 18/10/2016 Location: AustraliaPosts: 874 |

Hi Mick, I've sent you an email. The Mup3 is the ants pants but I have one (somewhere) if you haven't already posted it? (I have packing boxes everywhere). I should add that the little board you helped me with a few months ago is fantastic too. I have them all over the house on my HC-12 network reporting the temperature "up the pole" and locally, all in a small box with a ST7735 128x160 LCD - you must add that to your repertoire too. Cheers, Andrew |

||||

| Andrew_G Guru Joined: 18/10/2016 Location: AustraliaPosts: 874 |

Well I'm sorry to report that after running well for a couple of days/nights the remote has failed again! Re-booting every ~5 seconds. In one more attempt I: - disconnected it from the 5V supply, reconnected it and it failed immediately - brought it inside connected it to the console's 5V supply and it worked (I have previously tried all sorts of 5V supplies to no avail but this may be an issue?) - took it back outside and connected it to the original 5V and it is now working - I touched NOTHING inside and this only took say 5 minutes so not much could have changed. I'm keen to get to the bottom of the problem because a new version might just replicate the cause. I'm beginning to think that it may not be as simple as an ingress problem, possibly a 5v or code issue (but it is not as simple as me posting the code here - yet). I need to do more diagnostic thinking and will start by temporarily moving the remote, still outside, but closer to my PC so I can connect the console and really see what is happening. I'll get back to you all when I have something to report. Cheers, Andrew |

||||

TassyJim Guru Joined: 07/08/2011 Location: AustraliaPosts: 6452 |

5 minutes is long enough for the internals of the unit and/or power supply to cool down sufficiently to work again. Try a big capacitor across the 5V supply? Jim VK7JH MMedit |

||||

| Andrew_G Guru Joined: 18/10/2016 Location: AustraliaPosts: 874 |

Hi Jim, I've got a 1,000uF (10V) electrolytic - would that do? Andrew |

||||

TassyJim Guru Joined: 07/08/2011 Location: AustraliaPosts: 6452 |

'If' the problem is the power supply, it should help. Jim VK7JH MMedit |

||||

| Andrew_G Guru Joined: 18/10/2016 Location: AustraliaPosts: 874 |

Hi Jim (et al), The 1,000uF Cap is in and working and back up the pole. I'll keep you posted . . . I was a little ambitious with the length of run for my connection to the console (via a FT232 USB to TTL converter, Jaycar XC4464). No real communication at all. Two quick questions: - what is the realistic maximum USB cable length from a PC running MMEdit to the converter and then to the MM? - I assume it is best to have the greater length from the PC to the converter (rather than from the converter to the MM)? (This ceases to be such an issue with BigMik's MuP3 because it has a 1455 chip on board but the first question still applies.) Thanks for the support, Andrew |

||||

| Page 1 of 2 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |