|

|

Forum Index : Microcontroller and PC projects : Perfect marriage?

| Page 1 of 2 |

|||||

| Author | Message | ||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

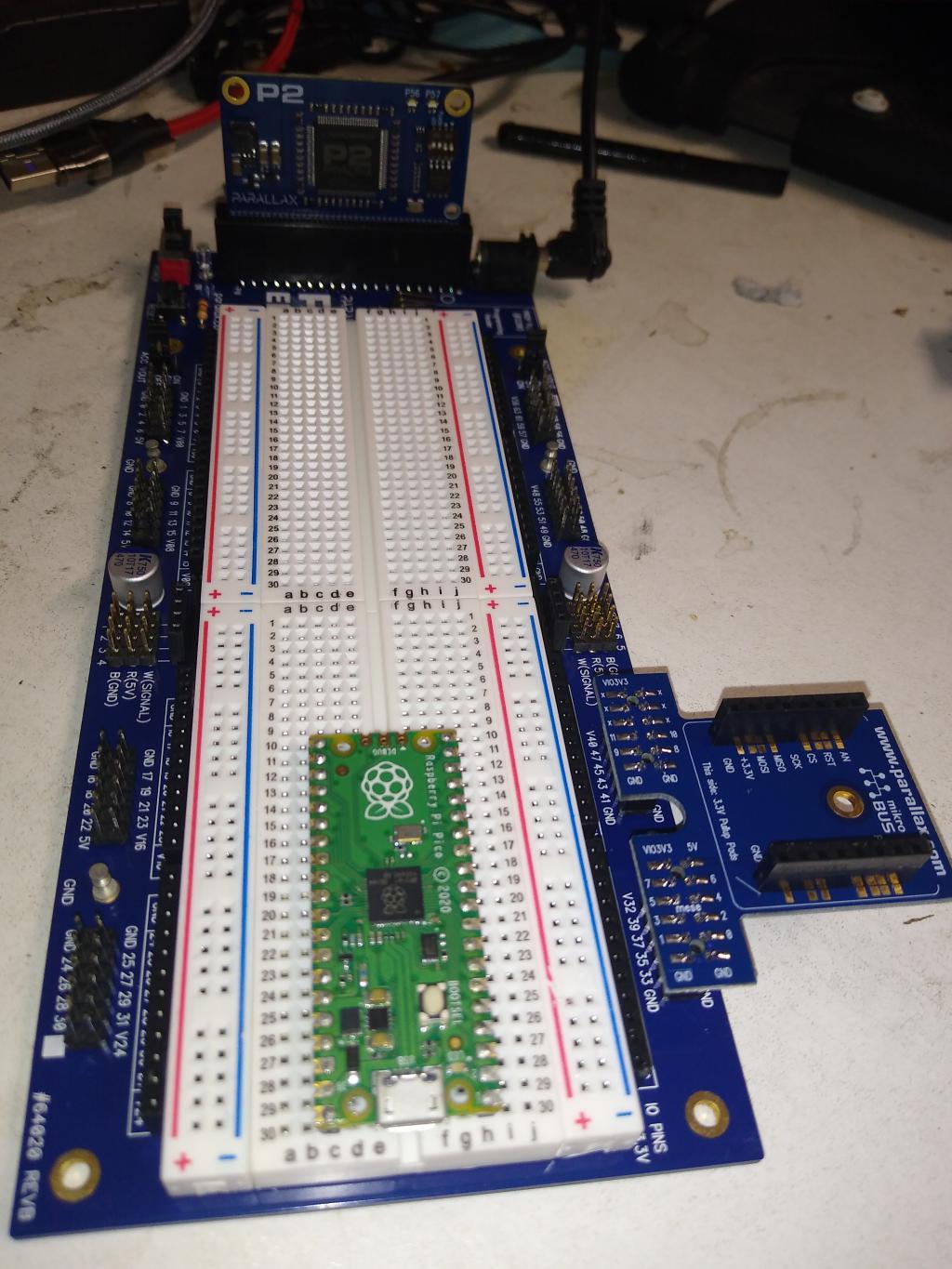

We'll see   |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8436 |

What do you want one of those funny little spinny roundy things for when you can have eight PicoMites connected as transputers via their PIOs for about half the price? ;) Ok, so it's a little more work... :) Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8436 |

How about this for a perfect marriage? A matching FPGA. Not as cheap as the PicoMite though. lol https://devbisme.github.io/tang_nano_user/docs/_site/index.html Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| JohnS Guru Joined: 18/11/2011 Location: United KingdomPosts: 4193 |

I don't fancy applying for the license. John |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8436 |

Apparently it's no problem. You can either get a direct licence that may take a day or two to come through. The only thing I'm a bit unhappy about is having it tied to a mac address. Or you can get a temporary licence that has to keep updating from a server. The temporary licence looks a little dodgy to me as you seem to be "borrowing" one. Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| JohnS Guru Joined: 18/11/2011 Location: United KingdomPosts: 4193 |

Neither scenario is attractive. Not for me. John |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8436 |

If it gets popular there'll probably be a FOSS toolchain eventually. Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| CaptainBoing Guru Joined: 07/09/2016 Location: United KingdomPosts: 2171 |

agree. I really don't like the way tech has gone and you don't seem to "own" anything anymore. With re-licensing you are going to end up paying a fortune over time and risking having your stuff bricked when/if the company goes bust/gets bought out/decides to obsolete your stuff etc... besides the technical hassle and dependencies of applying the licence. |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8436 |

Agreed. Software by rental is vile. In this particular instance, though, the software is supplied free in either case, it's merely how it's accessed. If you get the direct licence it doesn't require renewing. I don't like it being tied to a mac address, but I suppose that's to prevent people just giving it away to everyone and they lose control of it. It's bad enough finding programming software for the older FPGAs anyway. They tend to drop support for the older chips with each release supporting the new ones. Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

16 cogs (cores), actually; Two P2s and One Picomite  Or 17 (18?) CPUs counting the Picomite I'm going huge overkill because I'm tired of running in to performance challenges. I want something that will out-gun the commercial high-end controllers that used to cost me thousands and that have too much of what I don't need but not enough of what I do need. Galil Motion Control boast that their flagship's onboard BASIC-like (but crude) interpreter executes at 25,000 lines/sec. Picomite, without over clocking is 4 X this. Every P2 pin is a "smartpin" that can handle DIO/DAC/ADC/counting/quadrature-decode etc., etc. Furthermore I am able to tackle anything without leaving my BASIC comfort zone and even with a lot of fast real-time stuff happening, I won't need a single interrupt (although they are supported). P2s BASIC is modelled on FreeBASIC The Pico will be ubiquitous and Parallax simply don't have an EOL (end of life). |

||||

| epsilon Senior Member Joined: 30/07/2020 Location: BelgiumPosts: 255 |

What would be the role of the Picomite be in this configuration? Can't its job be absorbed by one (or a few) of the cogs? Part of the huge overkill plan? Epsilon CMM2 projects |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8436 |

So you gave up on valves then? ;) 16 Pico-transputers might be even more powerful. True distributed parallel processing too, in theory anyway. :) I always thought the transputer idea was brilliant. Want more power? just plug another one in and tell the OS where it's links go. The OS will figure out how to use it. (P.S. - looks like The Gables is having a major makeover!) Edited 2021-10-14 05:55 by Mixtel90 Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

I guess a decent analogy would be a conventional CNC controller that is commanded by interpreted G-code. The master controller is the interpreter and the P2s will contain the compiled "black-box" functions that drive the actual machine. It's a real time saver to be able to edit machine sequences directly on the machine without having to compile, etc. The Mites also have lots of other neat capabilities such as file handling, watchdog, etc. The dedicated STM watchdog that I was looking at, cost more than the Pico (IIRC). A bonus is the multiple program slots; I might have stable code running but then I might issue an update. I could have the update in a separate slot so that if the user comes across a bug after extensive testing, they can switch back to the stable version. I don't do conventional CNC machines, I am in a niche industry where pretty much every project has its own specific requirements involving multi-axis coordination, master/slaving of axes, etc. Always a lot of code development and I need to keep it as simple as possible in order to not lose my posterior. |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8436 |

Many moons ago, when I was considering using PIC chips as small PLCs, I toyed with the idea of using two as a pair. They would share the I/O using a simple serial interface (probably I2C) and would also act as watchdogs for each other. I think it might have been feasible but I never pursued the idea. The "intelligent relays" came along and made it largely pointless. Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

We think alike...I like to have multiple devices, monitoring each other  As it happens, I have to shoot down to Birmingham, tomorrow to address a similar, unforseen issue. An older system where I have standalone motion control chips. Each chip has a 2KHz PID running and with an error trap; Error = Command_Pos - Actual_Pos IF Error > Error_trap then Shut_down The problem is that; Shut_down only stops the PID running. The "Drive_Enable" remains high (!!!) This means that if there is a problem between the Servo Amplifier and the motor, the axis can fly away. The motion chip guys are not able to modify this (code developer gone) and so I need to come up with another solution. Just another reason to have 100% open-source. |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8436 |

So the output from the PID remains high even if the software stops running? Even a pull down resistor on Drive Enable can't fix that. It's hardly a safety feature! :( --------------- Decided that I'd like to investigate FPGAs anyway, so I've ordered one of these. It's an older chip (Altera Cyclone 2) so the current software won't work on it. I'll need version 13.0 SP1. However, the kit is cheap, the software is free, registration is minimal and someone has produced a logic file for a Nascom-2 to run on it. :) Edited 2021-10-14 17:37 by Mixtel90 Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| epsilon Senior Member Joined: 30/07/2020 Location: BelgiumPosts: 255 |

What would be the role of the Picomite be in this configuration? Can't its job be absorbed by one (or a few) of the cogs? Part of the huge overkill plan? I guess a decent analogy would be a conventional CNC controller that is commanded by interpreted G-code. The master controller is the interpreter and the P2s will contain the compiled "black-box" functions that drive the actual machine. It's a real time saver to be able to edit machine sequences directly on the machine without having to compile, etc. The Mites also have lots of other neat capabilities such as file handling, watchdog, etc. The dedicated STM watchdog that I was looking at, cost more than the Pico (IIRC). A bonus is the multiple program slots; I might have stable code running but then I might issue an update. I could have the update in a separate slot so that if the user comes across a bug after extensive testing, they can switch back to the stable version. Thanks, that makes sense. It looks like the P2 has a REPL for Micropython, but FlexBasic requires compilation, which is a bit strange. But even with a shell on the P2, it's good design to keep the controller separate, and the Pico does have all those other goodies you mentioned. Epsilon CMM2 projects |

||||

| scruss Regular Member Joined: 20/09/2021 Location: CanadaPosts: 96 |

This isn't 'mite related, but have you seen the work that Bart Dring has put into ESP32-based CNC and motion control? One core runs the real-time machine control, the other does a nice wifi web UI for a G-code sender. Here's one of his boards: https://www.tindie.com/products/33366583/tmc2209-4-axis-grbl_esp32-cnc-controller/ |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

Here's one of his boards: https://www.tindie.com/products/33366583/tmc2209-4-axis-grbl_esp32-cnc-controller/ Hey, thanks for the link; he has some neat products. However, I get pedantic when it comes to motion "control". For his target market, no problem but... CNC is an acronym for Computer Numerical Control. How is anything "controlled" when it is simply bombarded with pulses and assumed to have reached desired position? I call this Computer Numerical Command because there is no feedback to verify that the motor actually reached the target. Industrial CNC, robotics and motion control utilise closed loop servo systems. In my case, there are TWO feedback encoders for each axis; one is directly coupled to the motor shaft to ensure loop stability and the other is mounted directly to the load to ensure positioning accuracy. Unless a commanded position move can be verified, it cannot be considered under "control". Dual loop |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

@Mixtel90 False alarm. The machine wasn't running away at all. They had a 45mm tooling die mounted but the software was told that it was zero mm and so the machine was doing as it was told....linear axis smashing in to the tooling die. However, at least it alerted me to the fact the motion chip was not removing power in the event of excessive position error. The PID motor command drops to zero but the servo drive (amplifier) enable remains on. Should the servo drive throw a wobbler and ignore the command, it could potentially take off @2000mm/s. Fortunately, the MM E-100 receives a "status byte" every few ms and this includes an error flag and so now the E-100 is constantly monitoring. FPGA It would be cool if you started a thread on this, so that we could follow (?) This stuff is on my if-only-I-had-the-time list  |

||||

| Page 1 of 2 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |