|

|

Forum Index : Microcontroller and PC projects : Upgrading from relays to PicoMite

| Page 1 of 2 |

|||||

| Author | Message | ||||

| PhenixRising Guru Joined: 07/11/2023 Location: United KingdomPosts: 1702 |

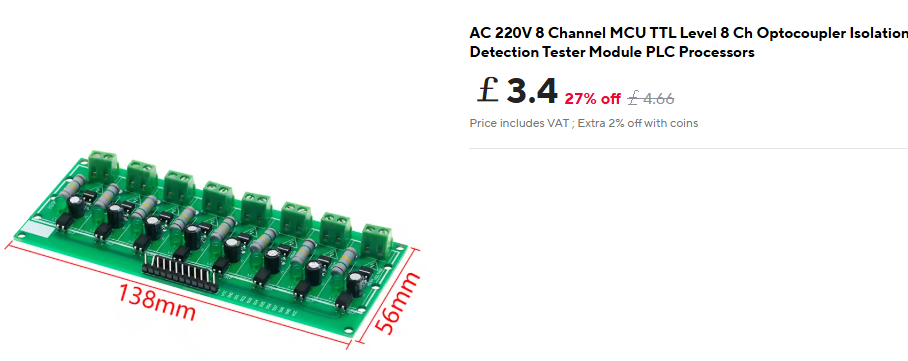

Went to help-out a new customer whose production was at a standstill. Big panic. All they do is shot-blast and powder-coat metal structures. I'm getting more and more of these odd-ball jobs through word-of-mouth due to the skills-shortage I guess. I cut my teeth (apprenticeship), building relay panels and this, like many I come across, was all relay logic. Piece of cake to figure the problem but the simplest fault puts these companies completely out-of-action due to the absence of diagnostics and trouble-shooting abilities. Staring at this panel, all I could think about was: PicoMite-upgrade required. However, the control circuitry is all 220V AC and I'd want the conversion to be as simple as possible. Outputs are no problem but there are a few inputs to deal with. Then I remembered an impulse purchase that I made awhile ago on AE: AC INPUT MODULE:  I know a guy who is constantly traveling the UK with his team, doing nothing but keeping these huge powder-coating ovens up and running and he commented to me that the biggest problem is the primitive relay panels, everything else is easily repairable. The potential for relay-to-PicoMite upgrades for many types of machinery is mind boggling.  |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8461 |

You'd think they'd put the resistors in all the same way round, that looks so untidy. :( Can't get a decent PCB assembler now... :( The price is ok though. :) The creepage distance under that big resistor could have been increased easily and at no cost. Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| PhenixRising Guru Joined: 07/11/2023 Location: United KingdomPosts: 1702 |

I share the same OCD  If I absentmindedly solder-in a resistor that doesn't conform, out it comes  |

||||

| Volhout Guru Joined: 05/03/2018 Location: NetherlandsPosts: 5628 |

I have no data to prove it, but the opto input could be slower switching than mechanical relays. Volhout Edited 2025-08-07 00:27 by Volhout PicomiteVGA PETSCII ROBOTS |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8461 |

They bounce less though. :) The "intelligent relay" controllers usually put something like 20ms delay on all inputs. Also, they scan the progran cyclically, which can introduce further delays. Relay Ladder and logic block programming would be nice on the Pico. :) Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| PhenixRising Guru Joined: 07/11/2023 Location: United KingdomPosts: 1702 |

Something like this |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8461 |

Yes, I remember that! :) I've run it on a PIC16 and it was rather good. Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| PhenixRising Guru Joined: 07/11/2023 Location: United KingdomPosts: 1702 |

What would be cool is building the logic on MMB4Android and then transfer to the Picomite. Nice sexy graphic symbols  |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8461 |

But we have sprites. :) Or a custom font, of course. Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| PhenixRising Guru Joined: 07/11/2023 Location: United KingdomPosts: 1702 |

Mechanical relays are quite slow and there's also zero crossover to consider. This is primitive stuff but no excuse for no diagnostics in this day and age. We can incorporate full documentation including a BOM showing alternative equivalents and suppliers etc. |

||||

| Volhout Guru Joined: 05/03/2018 Location: NetherlandsPosts: 5628 |

Played with that too. In the early days there was a problem with either ATMEL or MICROCHIP generating code with errors and running slow. I developped a PLC board for it for my brother, who was in process automation, and was sick and tired of the poor response that PLC vendors gave when it came to after-sales. But the PLC was never used in practise. The Management did not trust it. Volhout PicomiteVGA PETSCII ROBOTS |

||||

| PhenixRising Guru Joined: 07/11/2023 Location: United KingdomPosts: 1702 |

Yet they don't care about the quality of the programmer  That relay logic, yesterday; the panel and the schematics looked first rate but the logic left a lot to be desired. This is a huge oven and the circulation fan motor was 2-phasing and tripping out but the burners kept on burning. The oven has to overheat due to no air circulation to eventually shut down. An interlock would have only required two extra wires. Who the heck does this stuff. |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8461 |

That's weird. Normally you'd want the circ fan to carry on running until the oven had cooled down a bit. That's necessary to prevent hot spots forming in the lining (they always do in ovens and kilns). So you always kill the heater first. The fan should be shut down by the temperature sensor ideally. I wonder if it's been modified at some time? Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| PhenixRising Guru Joined: 07/11/2023 Location: United KingdomPosts: 1702 |

I suspected that but it was right there on the CAD drawn schematics. Correct though, when running normally, the circulation fans can be on for more than an hour after the burners shut down but in this case, motor dies and yeah let's keep on burning  |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8461 |

At the very least the motor overload should trip and take out the burner as well as the fan. And it should be a manual reset overload for a fault like that. It won't do their oven lining much good running it like that. It could start to crack as it heats and cools unevenly. Major money! Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| PhenixRising Guru Joined: 07/11/2023 Location: United KingdomPosts: 1702 |

What they paid for the new contactor is about £20 less than a VFD. I would love to build a new controller based on the PicoMite and VFDs with diagnostics. Smooth ramp up and down. DOL is brutal. Daren't suggest it because he's the type of guy who'll want to do it straight away and I have too much on my plate. This VFD that I put on the Bridgeport mill is working beautifully. |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8461 |

VFDs have come a long way and the prices have fallen as the prices of "heavy metal" contactors have been rising. 6xFLC puts a lot of strain on everything, especially when it's a high inertia load like a fan! Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| PhenixRising Guru Joined: 07/11/2023 Location: United KingdomPosts: 1702 |

So many possibilities; only when I received it did I learn that one can select VFD or flux vector mode (Field Oriented Control). VFDs tend to peter out below 10Hz but flux vector runs right down to zero RPM. Didn't need this for the mill but I selected it anyway and the response is smoother and quieter. Stick an encoder on the motor shaft and I'm sure I can close the position and velocity loop. Gonna grab another to play with. Another idea is; the amount of hydraulic plant that is running constantly that only has a 10% (or lower) duty cycle. Powering up and down is too stressful but how about spinning up on demand only. This is also a huge safety issue because safety can only be assured once all energy is removed. |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8461 |

Hydraulics is something else. I think the constant running thing is more about inertia in the system. It takes time to get the oil moving and up to pressure before anything can happen. Spinning up as needed might not always work. There's not a lot of energy being used even with the pump running as the oil is simply being returned back to the tank. Small systems like forklift trucks do spin up on demand (he said, having spent a number of years refurbishing forklifts and cursing the position of the microswitches on the hydraulics control valves!). Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| PhenixRising Guru Joined: 07/11/2023 Location: United KingdomPosts: 1702 |

Oh, it's the really nice Schneider TeSys stuff, manual reset. Everything is there but they didn't use it. |

||||

| Page 1 of 2 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |