|

|

Forum Index : Windmills : Southern Cross mystery bung?

| Page 1 of 2 |

|||||

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

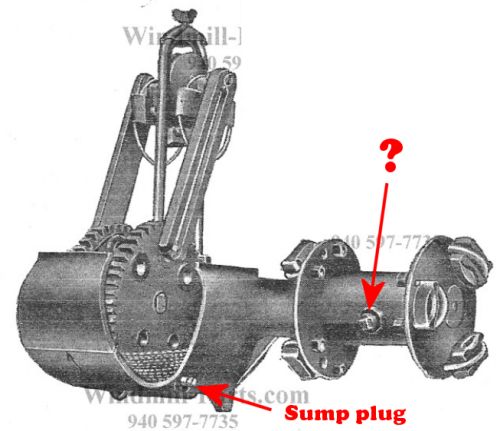

Hiya We dropped my Southern Cross windmill yesterday, literally. My neighbour Russel was over with his backhoe and we tied a chain around the mast at the 2nd cross brace down, about 4 foot down from the platform. Russel took the weight while I undid the bolts holding the tower to the concrete posts. I was a little worried the mill was top heavy, so I tied a rope to one leg and held on as Russel lifted the mill clear. Well it was top heavy. As soon as it cleared the concrete posts it tilted over, and I couldn't hold the rope tight enough, started slipping and burning like hell so I let go. The windmill, tower and all, did a mid air flip and the turbine hit the ground. All OK, but bent turbine. The turbines on these things are made of segments that can be separated, and it only bent 2 segments back, so I can easily fix it with a vice and hammer. I took the tail and turbine apart, and slid the nacelle off the tower. I enjoy working on these old mills, its all split pins, 1/2 inch nuts and gear oil everywhere, like working on a old car. I do have a question though, there is a bung on the side of the turbine hub, and I dont know what its there for. The graphic below shows it.

This isnt the sump bung, but its the same size, on the side of the hub. Would anyone know what its for and if I'm supposed to do any maintenance with it? I did have a link to a exploded view of the old Z series Southern Cross, but the link doesn't work anymore. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

Glen I don't know anythning about these mills but if there is a drain plug then this may be the fill plug? Fill plug for some sort of lube or gear oil. Jim |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Darn good question. When I built the new bearing on mine (used aluminium not tin) I pondered this for a while. From memory, it lines up with the oil escape hole in the bearing outer journal. These things are cunningly built to be maintenance free for the most part, like those two rings at the top that oil the upper journals each pump cycle... pure genius. However, my best guess was this: When the thing rotates, the oil is picked up by the primary gears and lifted onto the spring around the front shaft . It runs down the spring with help of the rotation, and delivers the oil to the shaft/journal interface. Here it seeps down the shaft and exits at the front and through the hole at the top of the nose casting and the journal end. The nose casting is about where that bung is. The excess oil leaves the nose and fills up the hollow inside the hub. There is a ridge that keeps a fair bit of oil in the hub, maybe to protect journal at the nose end, I'm not sure. When it rains, small amount of water may run down the casting, and along the bearing nose casting until it drops into this oil reservoir. It will then become a water /oil reservoir with access to the nose end. I suspect the bung is to drain the excess oil and water periodically... but just a guess. It would allow you to know how much oil is getting through as well I suppose. The fact that mine lines up with the oil hole in the nose may be that at installation you could prime the bearing, but this seems obscure too. Downwind may be the man to shed some more light on this. ............oztules Village idiot...or... just another hack out of his depth |

||||

| Barry T Coles Senior Member Joined: 30/07/2009 Location: AustraliaPosts: 109 |

I am assuming this is a Southern Cross, if not then dont rely on the statement below. It's the top level for the oil, you wont have a dip stick to check the oil level, this is the dip stick you undo that bung and add oil through the oil filler opening untill it starts to dribble through the hole, then replace the bung. You will notice from the pic that the bung with the ? is just below the centre point of the cogs to the left, this ensures that the turbine shaft & the pump cogging are lubricated. The same oiling method is used for outboard motor legs you undo the bottom bung & screw the oil can into the bung thread, you then undo the top bung & push oil in untill oil seeps out of the top bung hole. Cheers Barry I need to learn from the mistakes of others. I dont have the time to make them all myself. |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

Gizmo; It is likely the proper level of the lubricant in the hub. If this hub is isolated from the crank gears which it appears to be. I do not think this would be a fill plug as this much cold oil would be highly inefficient. When adding or changing the fluid, the hub should be level ,when oil runs out this is full. I'm Guessing here, On conveyor belt gear boxes this is a frequent design. edit; I decided to look for your missing link and learned again that guessing don't get it. Oz has pointed out the unique lube system but I still believe this is where the quantity of oil in the system is measured. The exploded view link would not load. this is home page. S.C.. Model Z Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

No Greenbelt, oil measure is a simple line in the cast. The weather cover comes off, and exposes the open sump completely.... to fill, just tip er in. This bung is in the rotating hub itself. Open to the air on the backside with a 1/4"gap all around. It has no path to the sump, except through the spindle shaft/journal interface (maybe 1-2 thousandth of an inch). Oil will seep out of the journal end (means the oiler is working) very slowly if the journal is good, and not so slowly if there is plenty of wear. The idea is that every so often, you refill the oil sump, and it uses it up via the journal. If you forget, the oil runs out and the bearing journal suffers. In my case it probably isn't often enough.

.............oztules Village idiot...or... just another hack out of his depth |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Gizmo, tut, tut, tut. You normally take the head off first before lowering the tower. or at least the wheel and tail. As for your question. I think its a remaining casting point from a past era. Many years ago most water mills use to have a white metal bearing on the shaft. These gave a reasonable life and was easy to replace. The point you ask about use to have a grease cap in it in the earlier days and when the mill was checked you would give the cap a turn or two to squash more grease into the bearing. As bearings improved this became not required an hence the ball plug in it now days. I will double check on this next week as will be down country and one of the jobs while i am there is to change a head over on a southern cross mill. Its been a long time since i worked on one nowdays so the mind is a bit fuzzy. I had worked on many types in younger years but now they tend to blend together but a look see will bring the thoughts back. I will let you know. Pete. Sometimes it just works |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

Downwind; I'm Inclined to go with your analysis, I had forgot the old system before sealed bearings. Some of us old guys remember the water pump on the "T" Model ford and Dodge Flathead engines, eh. OZ. Note; It appears that AEROMOTOR is the Double first cousin of the S.C.windmill else they swapped blueprints. Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Now thinking? One of them had a locking pin set up like that that locked the wheel to the shaft. But i dont remember which make. Have you removed the ball plug Glenn? Pete. Sometimes it just works |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

I did remove the plug when I first bought the windmill, couldn't see much in there, so poured in some oil just in case and closed it up. I figure you cant have too much oil, it will just leak out if there's too much. Oz's explaination makes sense. Whenever I top up the oil, remove the bung and turn the turbine so it faces down. Any old oil and water in there will drain away, and it will fill with clean oil that seeps past the bearings. I wouldnt hurt to pour in a cap full of oil either. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Been thinking more on this, and with another good look at the pic. tells me we are missing something. The section in question is the wheel hub, this is fixed to the shaft, and the shaft turns and drives the mill. There is no point in lubing this hub. Except!! These mills were designed by a working person and not some office rat. Thought was given to assembly and disassembly for maintence, and this it normally done in the field on top of the tower. In many cases the wheel would be removed. Most wheels locked onto the shaft with a keyway some had a spline others a through pin. I think these ones were a keyway? The plug would be removed once all assembled and a grease cap fitted, heavy grease would be squeezed in to displace any air, this help to keep water out over time and any prevent any rust build up. The grease cap was removed once grease extruded each end and the plug replaced. After many years this allowed the wheel to be removed off the axle with little effort. These thing were built back when there was horse and cart and not a lot of changes made over time. There was no backhoes or cranes or cherry pickers to work up the tower with so good design and thought was needed to maintain the mill. When i use to work on these we would tie the wheel off to the tower and slide the complete wheel and hub off the shaft and let it hang there while the head was repaired then pick the wheel up and slide it back on the shaft after. Much easier than hauling the sucker back up all the way from the ground. To lift the head assembly up i would stick a length of 3" pipe up through the tower and above the tower. A pulley block would be hung off the top of the pipe, and would haul the head up with the pulley blocks and drop it in place. Put the wheel on, connect the tail and pump rod . A few hand spins of the wheel to ensure it would not bottom out or top out in the pump and damage the drive line. Set the mill free to the wind and the job was done. I would have to say they were the dirtiest bloody things i have ever worked on, as most farmers are cheap buggers and use old sump oil in there mills and it gets thick and tar like over time and sticks to everything, mostly me! Good oil = good mill life. But as Oz said they dont always get checked as often as they should and run dry then wear, then leak oil, then get sump oil because they leak, then break, then some fool like me had to fix the dirty bloody things. I think they are a great invention, when standing at ground level now days. Pete. Sometimes it just works |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

EDIT: scrubbed the post and wrote this instead. Something is not making sense here. There is no provision for keeping any grease in here.. it is open at the back?? A grease cap would not work for the same reason.. it's on the hub, not the cast. All the ones I have worked on over here (maybe only a dozen or so) have keyway.... but no allen key or grub screw or square screw. All were interference fit. No prayer of getting the wheel off the shaft up in the air, we just dropped the two grub screws in the primary gears and slid the shaft and wheel out of the gear box. I wish we could have gotten the hub off the shaft like the ones you had there Pete. I used the 50 ton press to get some of the shafts out of the hubs. Good grief, I just had a flash. That hole in the cast may have been threaded. I vaugely remember a grub screw there.... was it to keep the white steel bearing from turning???? Gizmo, if you take out the bung, and find a grub screw, I bet it is just to keep the white steel from turning or moving in or out. It is very soft, and would not press fit too well and stay put... it is more like lead. If I had a decent memory I'd be dangerous. I have another up in the scrub someone dropped off. I will have a look at that one and report back tomorrow. ...........oztules Village idiot...or... just another hack out of his depth |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Earlier than grease nipples Oz ....Grease caps. The ones you packed with grease and then screwed the cap down to squash the grease in. Only female things had nipples back when some of these were made. What else has stood the test of time like the water mill and still works?? Pete. Sometimes it just works |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Ok. It does appear to be as I suspected first off. I went up the scrub and found this: It was not well. Fell over in a storm and the owner dumped it here. Here is the clearance from the hub to the casting. There is no way a grease fitting of any kind would be useful here. That theory is out I think.: Here is the offending bung. It is straight through the hub to the big cavity. Note, the part of the casting with the bung, does not hold the shaft. That thinner last 2" or so is the only part that contacts the shaft steel. It has no grub screws, pins or any other mechanism to lock the shaft in. It is multi ton press fit ... and thats it. Any other system would not work, as there is not enough shaft to sensibly stabilize the hub to shaft if the fit was not very very very tight. For those curious, this is how the spokes are set up: Here is the inner of the hub. 80% of it is hollowed out. You can see the ribs there. These keep the oil from the shaft rotating around the inside for reasons unknown. I suppose it does keep oil around which is good. This next shot is the clincher. Notice the teardrop depression in the cast coming from the hole. This directs the oil away. It is this hole where the oil from the journal exits, so it leaves from the highest point, so the shaft should be floating in the oil in the journal. It weeps out this hole, and runs down into the hub ribs. So I think that about covers it. That bung does no more than empty whatever water and oil has accumulated since the last service. Half the bolts snapped while I took this apart Gizmo... you'd better be thankful  ..... and that doesn't count the ant that took a chunk out of me as well.... ..... and that doesn't count the ant that took a chunk out of me as well....

...........oztules Edit: A few posts down, Greenbelt links to an explanation of the self oiling mills. It turns out the oil runs out the end of the journal, into the hollow hub, where those ribs keep it captured.... as I said.... BUT- It then drops down during rotation and runs INTO that rear drop not out as I stated.... and then is directed back to the gearbox. Sadly I have never seen a front bearing with enough white steel left to ascertain this, and so I have rebuilt my aluminium one wrongly.. it doesn't return oil to the gearbox. With the water and dust mixing in the hub with the oil, I'm not sure this isn't a bad thing... I won't be changing it, I'd rather give it new oil. end edit. Village idiot...or... just another hack out of his depth |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Thanks Oz, I do appreciate it. Its kind of sad to see the old mill lying face down like that, but at least it got one last chance to be usefull, and on the internet to boot

Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

This one will run again. Just will be a while until I get around making a new shaft and bearing... and fixing up the hardware... and ... and ... and ... ..........oztules Village idiot...or... just another hack out of his depth |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Oz, Is that a southern cross mill????? I didnt think the SC had spokes like that or a mill cap shaped like that. It looks more like a colac mill or Varco to me, but it been a long time and not sure. Most of the mills in the southern area were Varco, Metters, or Colac and the SC was more to the north of Aust. with only a few in the southern area. Did the ant survive. Pete. Sometimes it just works |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Yep, a SC mill. ZA1 (you can see it on the mill casting second picture. ) The spokes are supposed to be straight, not like the picture.... this one has taken a fall and rough handling from a tractor. I admit they look like a mangle wheel arrangement at the moment, but they will straighten out ok. I will recover from the engagement... Mr ant will not. ..........oztules Village idiot...or... just another hack out of his depth |

||||

| isaiah Guru Joined: 25/12/2009 Location: United StatesPosts: 303 |

the bung hole in question is for helium gas turn bung to the top fill with helium gas and mill wont fall to ground and makes reinstallation much easer. '  ' ' ' ' ' '

the soft steel is bearing babbitt. URL=http://www.motherearthnews.com/Renewable-Energy/1973-11- 01/The-Plowboy-Interview.aspx>The Plowboy Interview[/URL> |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

I'm a little late arriving at this thread. Ran across this Link and there's a picture of what appears to be a "new" one of whatever it is you've shown in your picture of the one lying face-down in the turf. I've always thought this type of windmill would have been much better had its inventor used a worm-and-down-gear setup driven by a three-blade turbine. That way there would be both speed and power. If the down gear was 100 to 1 or more, it could lift water from the other side of the world (almost)! A friend has an old, working Southern Cross mill in his front yard just for the fun of it. I'm 6'6" tall and tip the scales at about 280, but on even a slightly-breezy day, this thing can lift my body weight up and down its 5 or 6-inch travel almost effortlessly. Maybe I'll put one of 'my version' together as soon as I get all my other projects completed. That should be somewhere around the 12th of never! Edit: If you click the above link, then click on the green "Motor and Gearbox" link near the center of the page below the pictures, there is a dandy exploded diagram. Unfortunately the stopper plug in question is not labeled. Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| Page 1 of 2 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |