|

|

Forum Index : Windmills : New Farm mill ready to go ~1KW.

| Page 1 of 4 |

|||||

| Author | Message | ||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

Lashed out and bought a Phillm dual after I saw the excellent blade mounting solution, been umming and arring for 6 months now (thanks Phill for putting up with me and the endless questions) Here's some pics, I know there was some discussion over the colours people wanted from Phill, so all the bits that weren't painted, I allowed the kids to choose, looks pretty smart! Have 2 sets of stators set aside, hoping for the two 100S (one in star and one in delta) to be good for over 1KW at 500rpm and the two 80S wired as 7x2C (one star and one delta) Twisted the poles on all of them and varnished them too, even painted the stator support rings! Here's some pics for people to drool over, should be up in a month or so -waiting on the solar guy and sparkie, trench for the power and tower to go in -sorry no pics of that yet but 7m monopole tilting! Weighs in at a hefty 43KG all up Bugger photo doesn't do justice to the purple, looks blue in the pic! Luck favours the well prepared |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Karl, That tail is one of a kind , the girls did a top job . Looks like the Aluminium blades are also painted . Hopefully all the services go in soon and we can start to see some good results PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

Yep, blades (and tail) in aluminium etch primer, then flat white basecoat, then gloss white topcoat, should keep them in good nick for a few years yet! Plenty of doses of loctite, bearings to the masthead, F&P shaft to the F&P bearings, hub centre to blade mount handfull of 3/8" nylocks for the blade bolts and a handful of washers. Looks again like a move to Perth is on the cards, wife flying over next Friday for job interview with BHP, thats two in as many months! one of a kind! Couldn't let anyone down! Luck favours the well prepared |

||||

| Perry Senior Member Joined: 19/11/2009 Location: Posts: 190 |

Congrats Karl. Looks like a fun set up. Nice paint too. Perry |

||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

Super Sweet  Jim |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

Unfortunately short of the paint job the

goes to Phill, the tooling side of things and the accuracy required to get smooth running and thus longevity are beyond my equipment at this time. the next "lucky customer" gets the one with the tail mounted with bearings for even smoother furling. I did read an interesting article that said wind turbines should be at least 5 times the height of any obstacles within 300' --a really big ask! Tower is only 7m high, perhaps a stretch is possible later on with guy wires added up top. This beggs the next question..... I have 100M of cable 16mm2 cross sectional area do I go 45m from the house and run double cable (16mm2) in which case i will loose approx 3% in the cable or do I go 90m from the house and run single cable. in which case I will loose 9% (at 1000W) My thoughts are... Volt drop almost doesn't matter as turbine will happily make more than the 55V required for charging and thus should gain some efficiency by being allowed to run 4-5V higher than the batts/inverter end of things. 90-100W lost at the top end is almost irrelevant as the low end gain from being further away from obstacles and allowing the turbine to run in smooth air means that it will make more power more of the time and at lower current the losses will be linearly less. I'm heading up there on Sunday to start digging the trenches...  Luck favours the well prepared |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Karl Losses are a fact of life so as long as the loss dosent exceed the gain all is good to get the last 10% of efficiency can cost 90 % of the project. All the best Bob Foolin Around |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

Progress update Backhoe digging the trench and us backfilling Hole Inspector Sophie Hole completed View back to House Wind turbine after balancing and final assembly temporarily mounted on a beam in the garage. Now for the special part -I spent some time getting the stators exactly set up so that one stator pole is in-between the other stator, result....... with the door open and a few windows open behind it..... The windmill would sustain about 100rpm IN THE SHED!!!!! (no load but nonetheless pretty bloody happy with that) Lastly, dropped in to see Haydn from Eastcoast green energy in Stratford -(he's the guy doing my tower and puts up a turbine or two a week!!) and showed him the mill Here's a quick narrative... -Chinese mills furl but dont like coming back into the wind how did you deal with furling? -Adjustable offset Response -Brilliant How do you deal with blade angles- -Adjustable Response -Brilliant The tail should be allowed to sit 10deg in the oppposite direction from furling side did you account for that Yep, adjustable - Response -Brilliant How about tip runout what are you doing for that ahh mate thats adjustable too what do you think of these blades....... WOW- nice Whats with the exposed stator, laquered 3 coats, shell be fine Whats the kicker on the tail? holds it into the wind better for turbulent sites Whats with the fridge and capacitors? Halves the cutin rpm?......say what...how? long story but I've got some really smart mates, can be done for the chinese mills too. Geez -is there anything you didn't think of? So how many of these puppies can you supply, how much? If you get 1000KW/HR/year out of this puppy, she's worth at least double that! K.So whats the verdict? Hadyn, well mate I flog the chinese turbine caus the other stuff doesnt work or costs the earth so in comparison, looking at the construction here.. Chinese = turd, SOMA = turd, Whispers =turd that needs a howling gale to make anything! this = gold, but needs sliprings to be saleable Needless to say I was bloody happy with that! and then we started talking OZ AXFX and eyes really lit up. Luck favours the well prepared |

||||

| HeadsUp Regular Member Joined: 06/12/2009 Location: AustraliaPosts: 43 |

noise shouldnt be an issue that far from the house whats the rule for cable depth in your state ? happy daze is a home made anything making your own power  |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Top Marks for the whole lot Karl. Cant wait to see the output when you get it logging. All the best Bob Foolin Around |

||||

| Perry Senior Member Joined: 19/11/2009 Location: Posts: 190 |

Looks great but for putting up a turbine or two a week your tower installer doesn't seem to know the first thing about turbines. Maybe he just does towers and has never seen a turbine. With the exception of the caps the rest is all turbine 101 stuff. You should direct him to this site and scold him for concentrating on Chinese turbines. Perry |

||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

Karl your all most there. You will be pleasently surprised how efficient those blades are.  Jim |

||||

| neil0mac Senior Member Joined: 26/12/2009 Location: AustraliaPosts: 210 |

You didn't use one of those u-beaut mercury thingys? (Mentioned somewhere in these forums.) |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

Perry.. this guy is the most experienced person I have actually met having installed most of whats there on the market, the reason for the preference to the CHinese mills is the same as the bloke with the EXmork turbine that makes twice the power of its twice as expensive american turbine. The Chinese stuff-although not without its problems is still good value, even if you have to spend the same amount as the turbine itself making it right, then its still cheaper than the american alternative or our local SOMA turbines, once they are up and running smoothly-other than the furling not being right, the do work! Small wind turbines I have seen in the wild, whilst travelling the countryside, only 5 -not like there are lots of guys who have put up lots of turbines hence I respect his opinion more than a salesman from an online "store" I plan on going to visit a 20KW chine mill he put in a month or so ago for a look see. Luck favours the well prepared |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Karl I noticed a slip ring assembly on ebay for about $40 plus postage might be worth a look. Allm the best Bob Foolin Around |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

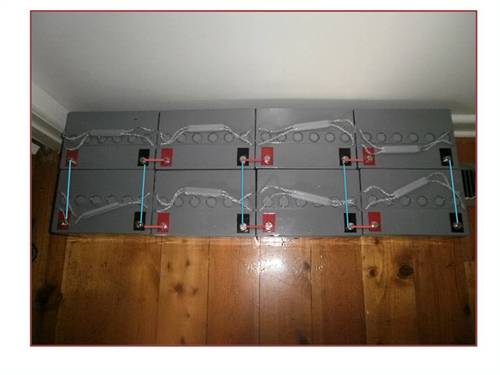

OK scored some batteries today 8x 80 AH SLAs all virginal but a few months old paid $600. Again amazingly enough the guy had an F&P windmmill in the backyard!!!, he had seen peak output of 600W using the 7phase into 48V -pretty good I reckon! Question should I parallel the 2 x 48V strings or parallel each 12V battery, then series the 4 batts? like the pic

Luck favours the well prepared |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

Bugger, made up links between all the batts pretty much as shown, (exception of the three blue lines in the middle as couldnt be bothered) then downloaded the instructions which say to leave a min 12mm airgap between the cells.. ah more flattening and drilling.... Luck favours the well prepared |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi Karl, the links appear quite thin. Are you planning on connecting a power inverter to this, or only a GTI. 10mm copper would be good. Some, flatten 1/2" copper pipe and drill some holes each end. thicker is better than thin. Gordon. become more energy aware |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Karl your work looks very neat and tidy but as Gorden said it looks light in the wiring. The last place you want to introduce any resistance is at the battery bank. Pete. Sometimes it just works |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

This was my schematic only... with powerpoint, Buss bars here Luck favours the well prepared |

||||

| Page 1 of 4 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |