|

|

Forum Index : Windmills : Starting a 1.8kW wind turbine project

| Page 1 of 2 |

|||||

| Author | Message | ||||

| MKHPhillips Newbie Joined: 08/02/2010 Location: Posts: 21 |

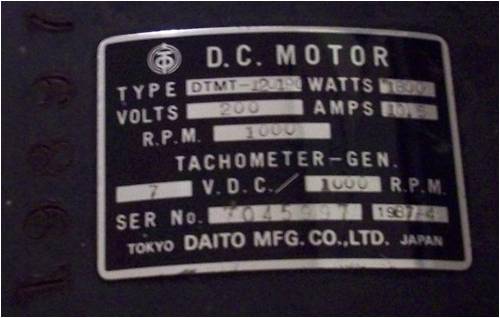

I purchased a 200 volt DC motor (permanent magnet, 15" long by 7" around, 85 pounds, 1 3/8 diameter shaft, 2 3/4 long, 1800 watts, 10.5 amps) from eBay for $61. It was a lot bigger than I thought. I will attempt to build a wind turbine and I want to share the experience with all of you. Plus, I will need your help. After cleaning it up, I hooked my meter to it. With a quick spin by hand, I received up to 30 volts. Therefore, I would not need to have high RPMs to charge my camper batteries (two 6 volts). I want to follow the plans at http://www.mdpub.com/Wind_Turbine/index.html Hub: I will need to get or build a hub. I’m not quite sure how to go about this. The shaft is 1 3/8” in diameter and 2 ¾” long. The shaft does not have any grooves in it and the end does not have a hole for a bolt. I’m thinking about some sort of small cap that will slip over top of the 1 3/8” shaft and then bolt an 8” round piece of steel to it. Blades: I also need to figure out the size of the blades in comparison to the generator size. I either want to build them out of PVC pipe or 2x4s. I’m thinking about 6 feet long for each blade. I also need to figure out which way to rotate the motor properly. I think it needs to turn clockwise. Wires: There are 6 wires coming from the motor (see pic). The red & white ones are thicker so I assume they are the positive & negative. Mounting: I was thinking about mounting it on top of a 2x6 at 5 feet long. Tower: I was thinking about 2” diameter piece of steel conduit. Not sure how tall yet. Charge controller: Don’t know yet. I may build or just buy. I have a feeling this will be quite an adventure. I already built three 60 watt solar panels for the camper but we are not getting enough sun (Rochester, NY) to keep the batteries charged.

|

||||

| MKHPhillips Newbie Joined: 08/02/2010 Location: Posts: 21 |

I started to build a hub today. When I connected a 12v car battery to it, it turned at 60 RPMs. |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

MKHPhillips; Nice Post! first, the shaft to hub connection can be accomplished with a common item called a taper lock bushing,It consists of two pieces, note when tightening the grip bolts , tighten all of them a little at a time to be sure that the tapered plug is seated evenly. I always use a brass hammer to tap on the plug and then re tighten the little bolts.There probably 5mm. 1/4" dia. 1-3/8"inch shaft is a standard size and can be found in industrial hardware supply and likely on the internet.your blade hub can be welded to the bushing part of the taperlock. Edit; You will likely want a stronger blade shaft for the blades and use a universal coupling to the Generator. There is a brand name (LOVEJOY) that is a good fix for this coupling.. The wires coming out of the motor, The Data tag shows a winding tap or an auxiliary voltage of seven volts. this could be a bonus to operate your safety devices. It is likely the red and white are the 200 volt leads The Green is the safety ground to the chassis and the small black and white are the seven volt output. The 2"conduit is attractive price wise but it does not have the stability you will want.Most people would like to have their mill at 30 feet or more to get the clean wind. Go for 3" Others on this forum have more knowledge in the blades department. Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

DC motors are not the weapon of choice, i think thats a stepper motor (other wires for position sensors). Its rated at 10A 200V at 1000 rpm. to keep the noise down and the prop from self destructing, 500rpm is more reasonable. A wood prop a far better idea than the PVC pipe this makes output in the 900W range for which a diameter of 10' (3m) would be reasonable. As far as matching a prop to it... going to be tough as we know very little about it, probably needs torque from 0 rpm.... best i can do good luck Luck favours the well prepared |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Hmmmm cut in around 80 rpm, max output about 150W.... odd sort of problem. You have only limited output power @12v, but a cutin speed to suit a large prop.... can't have both.... or can you? So maybe 5 blades will bring the TSR down to a reasonable level, with better torque. Blade size really needs to be 6 foot for the diameter not radius. 6' is as big as you would want for a 150w max output machine. Aim for a tsr of near 2, and maybe cut in will be around 8mph, but would need to furl early at about 20 mph or less, or fried motor is on the menu. A heavy device for 150 watts though. .............oztules Village idiot...or... just another hack out of his depth |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

MKHPhillips; Oztules has given you a good estimate of performance when designing for your stated requirements..What you plan to use it for. If you could feed 2 12volt batteries in series I believe your motor will output considerably more, cutin speed will be higher Which may not be desirable on a lazy afternoon vacation. I have quoted oztules below. OZ is the above correct.

You have only limited output power @12v, Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| MKHPhillips Newbie Joined: 08/02/2010 Location: Posts: 21 |

Thanks for the info guys. I plan on charging my camper batteries (two 6 volt). I have 3 solar panels (60 watts each) but they are not enough to keep the batteries charged (pictured above). |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

and Oh boy this (the link you posted) http://www.mdpub.com/Wind_Turbine/index.html I skipped over as we've seen lots of these BUT, this is for an AMETEK motor, mounting your 40KG generator to a piece of 2x4 is NOT going to work, nor I'm afraid is the tower made of 1" water pipe, and nor are the blades going to be particularly good for a motor your size...... perhaps swap it for something more suitable like a couple more panels or an AMETEK, then that project would be OK

Luck favours the well prepared |

||||

| MKHPhillips Newbie Joined: 08/02/2010 Location: Posts: 21 |

Greenbelt, I went to Home Depot and they did not have the "taper lock bushing". I guess I will have to buy it online some where. The shaft is 1 3/8". |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Sorry Greenbelt, missed it [quote] If you could feed 2 12volt batteries in series I believe your motor will output considerably more, cutin speed will be higher Which may not be desirable on a lazy afternoon vacation. OZ is the above correct.[/quote] Yes. The current in the windings are our limiting factor with this motor. If we double the volts, we can still get the same amps..... so more power. It will be capable of bursts well in excess of 150W, @ 12/14v but that would be about the safe upper limit continuously I would think. ..........oztules Village idiot...or... just another hack out of his depth |

||||

| wind-pirate Senior Member Joined: 01/02/2007 Location: CanadaPosts: 101 |

MKHPhillips; After reading your post. I have came up with a lot of Questions. You have given us alot of info about your motor, But not a lot about your project. What type of wind speeds do you get at your location? Are your plans, To place this turbine at this trailer location? I see a lot of tall trees in the back round. I see a Tower of 30 plus feet to clear the wind turbulants. Do you have a plan as the how your turbine will be built? 85 Lbs of motor plus your metal work/furling system, your hub and 5 blade arangement and tail. About 50+ more lbs. "Now about 130+ lbs" this is a lot of wieght to put up in the air. (And keep it there). If this falls over where will it land? The project you plan to copy, That motor and extras might hit the scale at about 40 lbs. Have you run any tests on your motor yet? rpm to volts/amps ratio yet? Might not be a bad idea before going any farther. I wonder how many amps you will get at lower rpm's Last question: Is this motor a stepper motor? OR(does it turn freely) Stepper's, You will feel detents as you turn it slowly. I'm Guessing you will reach 14+ volts at a low speed, and deliver low amps too. Ron THE Pirate. stealing wind & solar energy is fun |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

MKHPhillips; Here is a link to a distributor of couplings. For taper lock bushings, Brand names, (Browning, Dodge, Baldor. If mem. is right the Dodge is less money,Uses recessed allen head screws and weighs a ton. Browning, costs more and is well made, nice to work with. couplings Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| MKHPhillips Newbie Joined: 08/02/2010 Location: Posts: 21 |

I finalized the hub and created blades (out of 2x4's) yesterday. I balanced the blades and tested them in the wind using a large nail in the center. Today or next weekend, I will put the blades on the hub.

|

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Whats all that white sawdust stuff on the ground eveywhere?? Is the 3rd photo of the timber the final blade profile? Good to see your progress Pete. Sometimes it just works |

||||

| MKHPhillips Newbie Joined: 08/02/2010 Location: Posts: 21 |

Well, I could not wait until next weekend to test it. I mounted the hub and attached it to the generator. Since I did not have a pole setup yet, I used my backhoe and turned it into a mobile wind turbine. Pointed into the 15-20 MPH wind, I generated over 20 volts with no load. I quickly became discouraged with I hooked a load to it. I used a 12 volt headlight from a car. The blades quickly came to a stall. I’m not sure if this is what will happen when I connect it to a battery. If it is, then I will have to have larger & wider blades.

|

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

I saw the thread name, and expected a 1.8kW windmill. Looks like a 1.8kW brush motor used in a direct drive windmill application. The results you see are as expected, unfortunately, for this type of motor. In a direct drive application, this motor was probably rated for about 2000RPM at 1.8kW. At 200RPM, you would expect about 180W. A 24V battery loading will present a better blade loading. You will need a blocking diode with a battery. Looks too cold to be out playing windmills with that white stuff on the ground. Good luck with your venture. The photos give a different perspective to harsh conditions. Gordon. become more energy aware |

||||

| MKHPhillips Newbie Joined: 08/02/2010 Location: Posts: 21 |

I managed to cut 4 blades out of some 6” PVC pipe that I had lying around. They are 5 foot in length. I did not shape or sand the edges yet. The performance is much better than the wood blades and I am finally producing some good power. The next step is to build something solid to put this monster on. I still need to buy or build a charge controller. I am currently disconnecting the batteries from the motor when they are fully charged. I am not sure if the motor will hurt itself when there is no load on it (spinning freely).

|

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Hell it must have been a big bit of pvc pipe to get that much white dust on the ground

I dont think it would be advisable to leave it spinning unloaded. Ok for playing around testing etc but dont go away and leave it that way. Pete. Sometimes it just works |

||||

| keyskeet Newbie Joined: 28/02/2010 Location: United StatesPosts: 5 |

A note about your motor: Take it by a machine shop that has a lathe. Have them mount it and run it at different rpm's while recording the voltage output. Also it would be good to use a load source while running it. This will be very helpful in determing the ratio which you need to turn it in your design. Good Luck from Florida. Richard RCB |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

Support those blades ASAP!!!! not like wood PVC normally reserved for 1m diameter mills, not 3m (10') mills perhaps you could use the old wood blades as supports inside the pvc. BTW 2" pipe to support that monster is no good. Need 4" pipe. will need the usual stuff also, offset, tail etc Luck favours the well prepared |

||||

| Page 1 of 2 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |