|

|

Forum Index : Microcontroller and PC projects : SOIC Soldering

| Page 1 of 2 |

|||||

| Author | Message | ||||

| Andrew_G Guru Joined: 18/10/2016 Location: AustraliaPosts: 874 |

Hi, I made a complete hash of my first SOIC soldering effort (a 64 pin 32MX) but I won't give up! Too much solder on first touch then too much heat getting it off with wick then . . . I'd previously read Geoff's article, watched the video and read all that I can find on TBS etc. Some basic questions if I may: - I am using a temperature controlled Duratech TS-1564 iron with a 0.5 mm conical tip. 1) How important is a chisel tip? Geoff uses a 1.6 chisel but suggests a 0.8 chisel. I can't find these sizes for my iron but I'm thinking of a 0.5 conical tip gently flattened to a chisel - what do people think? - Solder. 0.7 mm solder is easy to get from my nearby Jaycar shop but 0.5 mm would be from RS (overnight at $Au52 for 250g). 2) I'm not fussed about the price but is 0.5 better than 0.7 mm? - Magnification. I wear glasses for reading. I tried a reasonably good illuminated magnifying glass on an arm and I have a set of x300 lenses that attach to my specs. I found this the hardest part. Jaycar have a 5 Mp digital microscope Here. (I'm definitely not going into production but I am happy to have the right tools for a job.) 4) I know that Silicon Chip recently did a couple of reviews but I'd welcome your comments? 5) How hard is it to solder whilst looking at a PC monitor? 6) I found it hard to hold the chip still for that first touch. Are there any other aids other than tweezers, toothpick etc? 7) Any other suggestions? Thanks, Andrew |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9872 |

Hello.  1) Chisel tip is preferred for "Drag soldering" SMD pins, but I expect that the conical tip would also work. I think the reason is just cos the solder pool will stay on the one side of the chisel tip, whereas with the conical tips, the solder can(and will) flow around to the other side of the tip as well as where you actually want it. Chisel tip size is a personal preferance thing. I use 2.5mm chisel tips on my iron, and it does all the 0.5mm stuff easy peasy. 2) IMHO, YES. I even have 0.3mm 60/40, but 0.5mm is OK. 0.71mm is really too big. The reason is simply that even with a tiny amount of .7 applied to your iron tip, you end up with WAY too much, and you get solder bridges - I think you have just discovered that.  With the 0.5mm pin-pitch QFP's used on the E64 and E100 units, .7 solder will make your life more difficult then it needs to be. Sure, you CAN use .7, but you need to be VERY careful to only put the tiniest of tiny amounts on the tip. With the 0.5mm pin-pitch QFP's used on the E64 and E100 units, .7 solder will make your life more difficult then it needs to be. Sure, you CAN use .7, but you need to be VERY careful to only put the tiniest of tiny amounts on the tip..5 solder you only need a tiny bit too. Basically, you should NOT be able to see a big blob of solder on the iron. The iron should just smoke when you put the solder on the tip, but you should not be able to see a blob of solder on the end of the iron. With the right amount of solder and flux, the solder will reflow to the pins on the 0.5mm pin parts like magic, and it won't even bridge the pins if you have the right amount of solder on your iron - despite the tip of the iron being wide enough to bridge about four pins at the same time.  3) ???? I assume you mean magnification there. I use 10x for soldering, and 30x to examine the result when finished. I use a microscope. A headset is not REALLY good enough for SMD, and if you plan to do any serious SMD work now or in the future, you need to invest in a microscope. They are more affordable then you think. See this thread for details on an affordable microscope - even cheaper then the Silicon Chip one they reviewed, but I find it is excellent. 4) See above... 5) I don't like it, personally. The scope in the thread above does come with a camera, but I prefer looking through the eyepiece. When you first start, it is a little un-natural, but you get used to it very quickly. 6) BLU-TACK!  Seriously. I put the board under the clips on the microscope so it can't move, then line up the chip, then press a little bit of blu-tack onto two sides of the chip, check the alignment again, then solder the OTHER two sides. Remove the blu-tack, and solder those sides. Blu-tack is great, as you can still push the chip around to line it up, and the blu-tack will move with the chip, but still keep it stuck down to the board. Seriously. I put the board under the clips on the microscope so it can't move, then line up the chip, then press a little bit of blu-tack onto two sides of the chip, check the alignment again, then solder the OTHER two sides. Remove the blu-tack, and solder those sides. Blu-tack is great, as you can still push the chip around to line it up, and the blu-tack will move with the chip, but still keep it stuck down to the board.7) Practise, practise, practise. I would always suggest people new to SMD and are worried about damaging parts, buy a cheap SMD practise kit from eBay or Aliexpress etc. Something like this SMD practise kit here for five bucks. Good luck. Once you master SMD, you will wonder why you were ever afraid of it, and it opens up so much more in terms of devices you can use for things - many of which are only available in SMD packages. I speak from experience. There was a time, not so long ago, when I was too scared to even go anywhere near SOIC or SOT23. Now I don't even bat an eyelid at those. Smoke makes things work. When the smoke gets out, it stops! |

||||

| DaveC166 Regular Member Joined: 13/09/2012 Location: New ZealandPosts: 44 |

High Andrew_g, I use a cheapish Jaycar 48w soldering station, also with a conical 0.5 mm tip, and .5mm fluxed solder This works fine for SOIC and 44 pin umites doing each pin inividualy, and using a flux pen as well I have spent a couple of hours filling steps into various Jaycar tweezers so that I can actualy hold down SMD resistors,caps, etc without having to use undue pressure and firing components all over the room. |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2979 |

GDay Andrew, Whilst I generally use a .5mm conical point I reckon a 1mm chisel is better as it holds the blob of solder better and helps with heat flow to the joint.. Why then do I use the conical...??? Because I have quite a few of the things.. I also would not recommend using 0.71mm solder get a good reel of `decent' brand solder... (stay away from lead free -- unless you must use it, also avoid the cheap CHinese solders.. they are woeful.) 0.3mm does not help, I feel 0.5mm is the optimal size.. PM me your address and I will send you a couple metres of 0.5mm Regards, Mick EDIT*** You MUST use a liquid or Gel flux as well. I apply it to to pads before I place the chip then tac two pins to hold it and apply more flux if needed. Mik Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

palcal Guru Joined: 12/10/2011 Location: AustraliaPosts: 2030 |

Hi Andrew, I am 73yo. and my eyes are a bit off, I use a binocular microscope similar to this . It is only $115US it makes soldering SMD a breeze. It has two spring loaded arms that hold the part whilst you solder. I use a .5mm conical tip and .5mm solder. I tried the chisel tip and drag soldering but I prefer the conical tip. As long as you have fluxed the pins, with a bit of solder on the tip I just move the tip up to the pin and voila it is soldered. I rarely have to use wick. But it is a personal preference, whatever you get used to. Paul. "It is better to be ignorant and ask a stupid question than to be plain Stupid and not ask at all" |

||||

| Andrew_G Guru Joined: 18/10/2016 Location: AustraliaPosts: 874 |

Grogster, Dave and Mik (et al), thank you very much for your replies and encouragement. Here is a summary of progress so far (please keep suggestions coming): 1) I'll get a second 0.5mm tip and gently flatten it to a chisel (I did observe the blob of solder not going where I wanted it to and a flat would help that). 2) I've ordered some 0.5mm solder from RS. 3) I've ordered the microscope that Grogster cited above. Whilst the Jaycar one is immediate and cheaper the AMScope model is stereo and directly above the soldering (much more direct than via a monitor). I had been looking at the AMScopes for a while now. 4) See above 5) I'm convinced that a Stereo microscope will be easier than a mono screen. 6) Blu-tac it is but I'll also reappraise my tweezers to help positioning. 7) I've also ordered a practice kit (although I already have 16 legs of a 64-legged SOIC to practice on . . .). and I've also ordered some 0.6 mm wick which may have helped my de-soldering (I already have a flux pen). I've PMed Mik to thank him for his generosity but may I thank you all too, not just for your answers but also for your encouragement - I won't give up! Cheers, Andrew |

||||

| GoodToGo! Senior Member Joined: 23/04/2017 Location: AustraliaPosts: 188 |

Howdy Andrew, Personally I use 0.5 conical tip on my Hakko 701. Solder is 0.7mm that's about 25 years old. (a roll does literally last a life time). Magnification I use a jewellers loupe. Actually I probably should invest in something else on this front, because your face is about 5cm away from the pcb when soldering.... And agree with Mik, use a liquid or gel flux. I use a gel, and it also has the added bonus of sticking the part to the board too. Afterwards I clean the pcb with isopropyl alcohol. I'm no expert, I've only done 2 of the 64 pin MX's, but I've done a lot of the little arse transistors, diodes, resistors, caps, etc. Hope the above helps, GTG!  ...... Don't worry mate, it'll be GoodToGo! |

||||

| Andrew_G Guru Joined: 18/10/2016 Location: AustraliaPosts: 874 |

GTG, thanks. I reckon that I need everything going for me (I'm not sure if your soldering hand is as unsteady as mine . . . too much beverage in my youth). Once all the gear turns up, and I've had some practice, I'll do an update on how it all turns out. Cheers, Andrew |

||||

| kkoppert Newbie Joined: 12/04/2017 Location: New ZealandPosts: 17 |

What can the Chinese do to solder? 63% tin 37% lead. OK the flux might be difficult but I use liquid flux anyway. Maybe 2 parts toothpaste tubes plus 1 part recycled lead acid batteries oh that's right toothpaste tubes are plastic nowdays rather than tin. |

||||

| kkoppert Newbie Joined: 12/04/2017 Location: New ZealandPosts: 17 |

Love the blu-tack trick. Works a treat. |

||||

| ajkw Senior Member Joined: 29/06/2011 Location: AustraliaPosts: 290 |

I used some blu-tac for the last chip I did however I put the blu-tac between and chip and the board. Was then very easy to align the chip. Once aligned l 'clamped' the chip down with my self-closing tweezers and began soldering. Once heated the Blu-tac oozzed out while the chip seated down a little further. The pins soldered to the pad and because the blu-tac had oozzed between the pin there were no bridges... Not quite what I was expecting but ultimately successful, however, now there is gunk between the pins - not sure if that will be a problem long term or not. Will try the above method (6) with blu-tac next time. Anthony. P.S thanks Bigmik for the MupTTL. |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2979 |

Hi Koppert, All, You would think it wouldn't be too hard for them to make a decent solder. But have a look at this thread BAD SOLDER I wont reiterate what I said in that thread but suffice to say the Chinese 0.3mm solder was absolute rubbish, The stuff I bought from Radio Parts was pretty good but really didnt seem to be any better/easier for SMD than the 0.5mm stuff. I recommended 0.5mm for the SMD work and 0.71mm for the THP stuff. Kind Regards, Mick EDIT **** Here is a link from EEVBlog about cheap solder brands. CHEAP SOLDER Mick Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

| robert.rozee Guru Joined: 31/12/2012 Location: New ZealandPosts: 2492 |

the quote halfway down that EEVBlog thread is classic: "Dr. Weidenhamer, his students and colleague Michael Clement found that some of the jewelry items they analyzed were composed primarily of lead and tin (the principle components of electronic solders), with minor amounts of copper. They found that copper, which is another component of printed circuit boards, will rapidly move into lead-tin solder when melted. They then analyzed 39 highly leaded jewelry items that contained more than 90 percent lead by weight and found that these contained significant amounts of antimony, a key component of the lead alloy in lead-acid batteries." i'd not thought about it being recycled before! i can see the one major problem with recycling solder (in a simple process) being that you can not easily separate the source material into leaded and lead-free. as a result, what you end up extracting could be any mixture of lead, tin, and whatever other impurities happen to get through. 63% tin / 37% lead is the optimal ratio for the lowest melting point, as you move away from this in either direction the melting point goes up. am surprised that car batteries get into the mix, usually these would be 100% recycled into new car batteries - this is what happens here in NZ and maintains a closed loop within that industry. cheers, rob :-) |

||||

| Andrew_G Guru Joined: 18/10/2016 Location: AustraliaPosts: 874 |

DHL delivered my microscope this evening (less than a week from USofA), I've unpacked it and turned the light on - absolutely magic (even at 10x, I don't dare try 60x)! I'm on domestic duties so a full report when I can but I am sure that with this (and all your other tips) the SMD world is at my feet . . . Cheers, Andrew |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2979 |

GDay Andrew, How much did it cost delivered and which one did you get? I sent a query to Amscope and they asked me for further details (which I subsequently supplied to them) but they have not yet responded back to me with a quote for one delivered here. Kind Regards, Mick Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

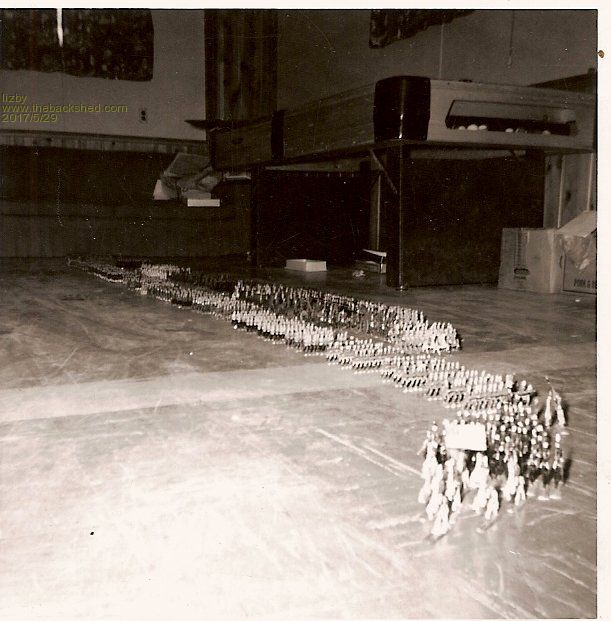

| lizby Guru Joined: 17/05/2016 Location: United StatesPosts: 3607 |

Well off topic, and I hope I may be forgiven, but more than 50-some years ago, I was able to buy 5-pound lead ingots from junk yards in the U.S--melted down batteries--so I could melt them and mold and paint lead soldiers--I still have some 1,500 stashed somewhere.  Nowadays it would probably be considered child abuse to allow a kid to handle that much lead. An environmental scientist friend once told me that I might have been smart except for all that lead. An Uncle also gave me lead from telephone cable sheathing--always very soft stuff. PicoMite, Armmite F4, SensorKits, MMBasic Hardware, Games, etc. on fruitoftheshed |

||||

| Andrew_G Guru Joined: 18/10/2016 Location: AustraliaPosts: 874 |

Hi Mick (et Al), The scope has an SKU of SE305R-AZ-E. Make sure that you specify 240V version (I did in the PayPal delivery comments). It is the one that Grogster referenced in post #2 above (thanks Grogster) (here ). The scope was US$179.98 and DHL shipping was US$89.29 (they offer a slightly cheaper shipping option). Total of US$269.27. (It was ordered on Tuesday, arrived in Melbourne the next Saturday and was delivered on Monday). (There are warnings on the www of cheap copies so I decided to go to the source). I'm still "evaluating" it but so far it is the bees knees. It has a choice of x1 and x3 in the main objective lens (which you rotate to choose) and two each of x10 and x20 diopter lenses which you insert and fix. Thus you have a choice of x10, x30, x20 and x60. It has rubber eye pieces which you can use or not. As people above have said x10 looks perfect for soldering, x30 for inspection (and x60 for checking the crystalline structure). (The one downside so far is that if I use the rubber eye-pieces I have to keep taking my glasses on and off - not its fault). Comes with a CD with the camera software which I'm about to play with. Cheers, Andrew |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

This version: 10x-80x Stereomicroscope starts at 98.18US$ and you can add options if you wish. It is basically the same but without bottom light (not needed for pcb) and without a camera. The optional cameras are very expensive so getting one from another source might be better. Microblocks. Build with logic. |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9872 |

I'm glad you are happy with it, Andrew.  I love my one.  I use it several times a week for any SMD work I need to do. As you have found out, 10x is fine for most work. I have never used the 20x eyepiece lenses, as they blow up the work too much! Yes, due to it's weight and size, the DHL is expensive on this one, BUT it is still much cheaper then the $1,000 one that Silicon Chip recommended in an issue not that long ago(with no disrespect to that unit, the magazine or the author), even when you factor in the shipping cost. That, and you probably would only ever need one, so it is a one-time-hit that big shipping cost. I would never hesitate to buy another one or another type from AmScope - boy, they make a huge range of scopes!  Smoke makes things work. When the smoke gets out, it stops! |

||||

| Phil23 Guru Joined: 27/03/2016 Location: AustraliaPosts: 1667 |

Hey Grog, What was the shipping cost to NZ in USD? Did a bit of looking at eyepiece cameras for my old Russian thing & cost 1/2 of a new scope. Edit:- Opps, just need to read above to be better informed. |

||||

| Page 1 of 2 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |