|

|

Forum Index : Microcontroller and PC projects : Using a Micromite as an industrial programmable controller

| Author | Message | ||||

| SimpleSafeName Guru Joined: 28/07/2019 Location: United StatesPosts: 351 |

It also depends on what you are using it for. I recently finished up a weigh scale transmitter that will read the load cells on the fork lifts. It transmits the weight of the parts on a pallet to a tablet. It takes the place of the oversized hardware that won't natively interface with a PC with something much smaller and much cheaper. And since it's a "Not for commerce" system, I don't have to fuss with certification of the scales. It's really hard to make something dangerous out of something like that. :) |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

I do use multi-drop but full duplex 422. There is only one master (MM Explore) and therefore the TX line is dedicated to it. All my slaves have ucontrollers and do their own real-time stuff. The bus is purely for messaging and each slave shares the RX line. It's a speak-when-spoken to arrangement. |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

Hey, I use Android tablets for my HMIs. Do you communicate via BT? Pretty amusing when I rip off a fridge-freezer sized operator's console and replace it with a (ruggedized) tablet. Client: "WTF!" It's a great solution. Download the app, pair the BT and we're up and running. I come across so many machines with dead/obsolete HMIs. If they are lucky, it's a PC based control and so they can plug in a regular keyboard, mouse and monitor. They look like hell though. |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8554 |

The beauty of using RS485 with the Micromite is that it's already hardware supported up to fast speeds. It also allows the use of multiple bus masters, so remote I/O can take over temporarily to send back essential messages to the main controller. RS422 only allows a single master and is also more expensive to implement - especially over any distance. It is, however, used a lot in the PLC world - probably because the software to implement it is simpler and the increased wiring costs aren't a problem for PLC manufacturers. The "big boys" in the PLC world link to their remote I/O over ethernet, but that option isn't available to the Micromite. No serial I/O system is ever going to get close to competing with local I/O, but it's the only way you will get even 256 I/O points on a Micromite system. Because remote I/O is virtually always "intelligent" nowadays there's no reason why things like positioners, PID loops etc should run slowly as their feedback can be virtually instantaneous - it doesn't depend on the main controller speed. What we could do with is a Modbus RTU or even Modbus ASCII protocol driver. 254 slave devices is usually sufficient. :) Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

Sure. The other reason that I like distributed solutions is to minimise the wiring rat's nest. One of these days, I intend to try going wireless (apart from power, naturally). I have had Bluetooth communications between the HMI and main controller for 7 years now and never a glitch. Users like it because the HMI becomes portable. Suspect a faulty sensor on the far end of the machine? No need to recruit help to manually trigger the sensor while you watch the diagnostic on the screen. Take the screen to the sensor. Can't find the schematics for trouble shooting? I include them in the HMI which can be plonked down near the area of interest for reference and can be zoomed for those with less than great eye sight. |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

No real limit to the possibilities with RS422 |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

RE: I/O expansion for the mites Available for both I2C and SPI. I have also seen I2C extenders for industrial use. |

||||

| erbp Senior Member Joined: 03/05/2016 Location: AustraliaPosts: 195 |

The SPI version is the MCP23S17. There is also an open drain version for both I2C and SPI - MCP23018 / MCP23S18. I am using the MCP23S18 - it is very versatile and useful. Cheers, Phil |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8554 |

IIRC the theoretical maximum range for I2C is around 8m. That's limited by the 400pF max capacitive load. You probably need 2k pullups for 3.3V too if you want a decent speed using something like cat5 or 4-way ribbon (although it sometimes gives up at around 5m-6m). That's still pretty useful, but better still if you put differential buffers on the ends. Then it can compete with RS485 over the long stretches. There is also a 1-wire slave to I2C master converter (DS28E17 - if you can even find one in the UK!) that will allow up to 100m between the I2C output from a micro and the converter chip. That looks useful, even if it's a lot slower. It might be worth experimenting with. Edited 2019-11-07 02:17 by Mixtel90 Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| lizby Guru Joined: 17/05/2016 Location: United StatesPosts: 3614 |

I've tested the P82B715 i2c extenders to 100 feet over cat5/6. PicoMite, Armmite F4, SensorKits, MMBasic Hardware, Games, etc. on fruitoftheshed |

||||

| Volhout Guru Joined: 05/03/2018 Location: NetherlandsPosts: 5694 |

Whatever you do, dont use i2c outside the box. Even if you can live with the length restriction, the i2c bus is NOT ROBUST. There are no recovery mechanisms on that bus, no error correction, and it is highly sensitive to electromagnetic disturbance due to its open drain structure. Please do not use outside a metal box. Volhout. PicomiteVGA PETSCII ROBOTS |

||||

| SimpleSafeName Guru Joined: 28/07/2019 Location: United StatesPosts: 351 |

Sorry about the late response, I missed this one... We try to avoid BT and WiFi since the 2.4Ghz spectrum is saturated in this plant. And 5Ghz is off limits. And any new WiFi connections have to be approved (which will happen when pigs fly...). BT we can barely get away with, but it causes headaches for the plant's engineer (one of my old coworkers). And since we are rather fond of him we try to keep him happy. We're using 900Mhz for our comms. It's clean and pristine. :) We use Panasonic Toughpads FZ-G1 since that is what the plant uses. They do fine. It'll be a cold day in hell before this plant uses anything Linux based, so Android is out. My previous employer used PCs for their HMIs, and you are right, they looked like heck. The newer stuff have Proface HMIs, but the older stuff ran VB6, RSLinx, and Access. Who could ask for anything more? LOL! I introduced them to AdvancedHMI, and they got religion. Basically, they saw the light. :) Edited 2019-11-08 09:57 by SimpleSafeName |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

Volhout. Hmmm, that's a bummer. At the very least, if I were reading external inputs over I2C, I would take multiple readings over a few milliseconds and if any disagreed, I would reject the reading. But what about writing to digital outputs, do those devices allow you to read the output register after writing...to confirm that the correct data was received? I am already a stickler for such measures, for industrial control. As previously stated; a Cycle Start signal, for me, consists of 2 sets of contacts on the Start Button/Foot Switch. One N/O and one N/C. I need to see transitions on both of those inputs and they need to persist for awhile before they are considered valid. Where I have machine actuators that can be on either one sensor or another, I check to be sure that: -I never see both signals simultaneously -I leave one sensor before I arrive on the other. |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

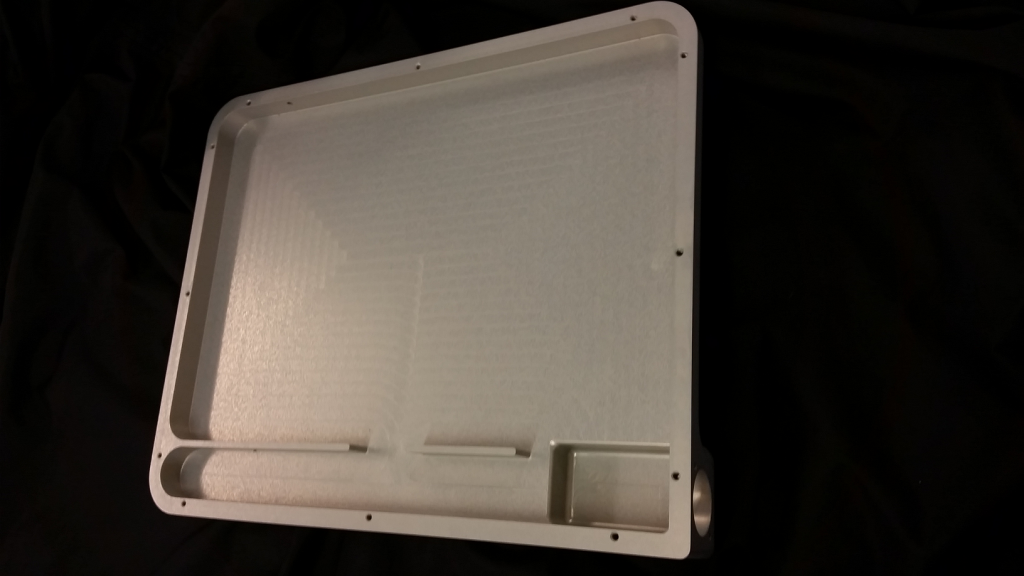

We're using 900Mhz for our comms. It's clean and pristine. :) We use Panasonic Toughpads FZ-G1 since that is what the plant uses. They do fine. It'll be a cold day in hell before this plant uses anything Linux based, so Android is out. I had considered ToughPad (I have several ToughBooks) but just not tough enough for my liking:     A nice, beefy Neutrik locking USB connector....much more resilient. I have another batch of these enclosures going through right now but these will be black anodized. I don't touch Linux but I code for Android and it is just as easy as MM-Basic. Yes, I was looking at 900MHz for wireless links, also. |

||||

| SimpleSafeName Guru Joined: 28/07/2019 Location: United StatesPosts: 351 |

Nice, they almost look explosion-proof. :) |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

With my coding? Yeah they need to be  |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |