|

|

Forum Index : Microcontroller and PC projects : Sonoff POWR2, Tasmota, mqtt, PiZW, bash power logging

| Author | Message | ||||

| phil99 Guru Joined: 11/02/2018 Location: AustraliaPosts: 2924 |

When choosing the inverter size, another trap to be wary of is the definition of "peak power output". I have an inverter rated at 600W continuous and 1000W peak, but it struggles to start a refrigerator that draws 0.3A at 240V = 72VA. After setting up a test rig I found the inverter can only sustain 1000W for about 1 cycle = 20mS. The motor start surge lasts around 400mS. |

||||

TassyJim Guru Joined: 07/08/2011 Location: AustraliaPosts: 6426 |

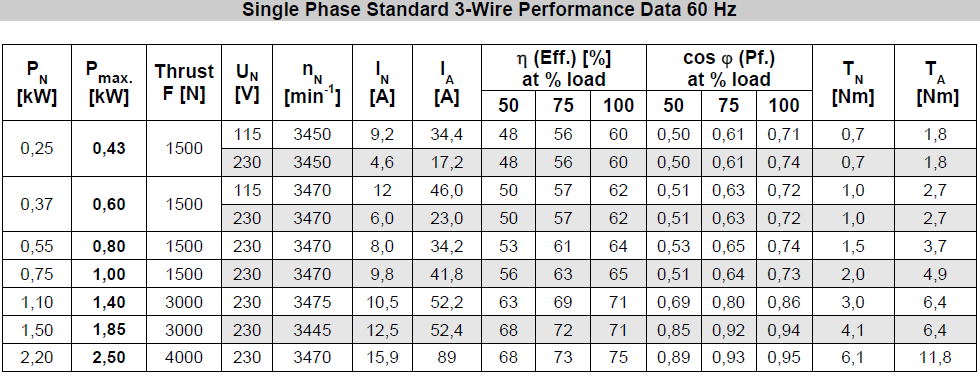

Some of the tables only look at Electrical power. With a 1/2 HP motor the 1/2 HP may refer to mechanical power out. There is a big difference.  This table is from my Franklin Electric bore pump manual. (3 wire includes earth) I have used the 60Hz table to make our USA friends feel the love. Taking the 1/2 HP (0.37kW) as an example. Power in = Volts X amps X power factor Power out = Power in X efficiency The table lists nominal power as 0.37kW and Pmax at 0.60kW For 115V, the current is 12 amps with starting current of 46 amps (That would be worst case) At 100% load Power in = 115 x 12 x 0.72 = 993.6 W Power out = 996.3 x 0.62 = 616 W ** matches the 0.6 kW Pmax in the table At 50% load Power in = 115 x 12 x 0.51 = 703.8 W Power out = 703.8 x 0.50 = 352 W I have never bothered to measure the starting current on the pump. I miss the peak reading meters I had to play with 25 years ago. I have CTs and CROs so maybe one day. I might even make a micromite powered peak meter. Jim VK7JH MMedit |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8436 |

Thanks Jim - excellent post! Those are nice, low inrush pumps. I suspect they are skinny, with a long, thin armature (lower inertia). Also, the load on a bore pump, once the pipe is full, is quite gentle as it only lifts from the water surface height, not the bottom. Up until my retirement I very rarely saw a motor with hp specification. They have been only been kW rated for many years now. The hp rating ones were usually reclaimed units for fans and pumps that were being re-used because they hadn't had much actual service use. We usually had the FLC to work with anyway, but we did occasionally get caught out with a pump that had to have an overload change at commissioning because the FLC didn't tie in with what we expected from the kW rating. Some of that was simply because the control panel was ordered before the pump and they turned up with a different rating! Incidentally, the starting current of a motor is always the same at a given voltage. It doesn't matter if the motor normally runs light or at full load. The value of the starting current is a function of the magnetization current, iron losses and ratio of armature to stator windings and these are decided at the motor design stage. The length of the starting current surge is dependent on the inertia of the armature and load - and sometimes (particularly with fans) it can be quite long. Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| lizby Guru Joined: 17/05/2016 Location: United StatesPosts: 3549 |

Right. If my inverter won't start the water pump (shallow well), I have a PICAXE cycle-slicing "slow start" circuit built which, at a minimum, will start a 1/3rd hp motor as tested. Thanks, Jim. I suspect that's what I'm seeing with the FLC calculators--they are assuming an input of 373 watts, not a working output of 1/2hp which is the consideration for the nameplate FLC. And indeed, since they can't know the characteristics of the specific motor in question, how could they know what wattage input would produce 1/2 hp of work? The pump is not easily accessible to me, but I'll try to get to it to see if it has an FLC/FLA number on it. I hope not to have to try the slow start circuit. PicoMite, Armmite F4, SensorKits, MMBasic Hardware, Games, etc. on fruitoftheshed |

||||

| lizby Guru Joined: 17/05/2016 Location: United StatesPosts: 3549 |

Here is my tracking chart with the water pump added. It's the blue line rising from -20 -- since I'm just looking at on/off, I arbitrarily set -20 as off and -5 as on. Similarly, the freezer off is -15 and on is 0. The chart shows a curve, which isn't accurate. Each horizontal period of resolution is 6 minutes. The pump runs for about 1 minute. It might be better represented as a vertical line, but I don't know how to do that with this google chart. The DR-Kit, LR-BR, and Up lines represent temperatures of the hot water feed pipes for my 3 heating zones. They're flatlined here because it's summer, and no heat is called for. ~ Edited 2021-08-21 22:11 by lizby PicoMite, Armmite F4, SensorKits, MMBasic Hardware, Games, etc. on fruitoftheshed |

||||

| lizby Guru Joined: 17/05/2016 Location: United StatesPosts: 3549 |

I added another Tasmota-ized Sonoff PowR2 inline with my boiler. It's summer, so it rarely comes on, but here it is: I didn't catch it on the Tasmota web page when it first came on, so didn't see the already averaged high load (not real peak), but it settled at 151 watts. It was on for 4 minutes and 9 seconds, and consumed (as reported by this device) 10 watt-hours. (That works out: 151 watts divided by 60 minutes per hour times 4 minutes equals 10 watt hours.) This gives me confidence that when I hook it up with the AIMS auto-transfer inverter (separate from the one for the water pump), the 100Ah battery will give me heat for some significant period of time if the power goes out, though I'm going to need more batteries if I am not to exceed a C/20 usage. ~ Edited 2021-08-27 02:13 by lizby PicoMite, Armmite F4, SensorKits, MMBasic Hardware, Games, etc. on fruitoftheshed |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |