|

|

Forum Index : Microcontroller and PC projects : CNC Milling Front Fascia Panels for TFT displays

| Author | Message | ||||

TassyJim Guru Joined: 07/08/2011 Location: AustraliaPosts: 6427 |

7.4 degrees before windchill at midday is not that cold. Use the "add hyperlink" button (4th from left) instead of just pasting the ling text. Jim VK7JH MMedit |

||||

| PeterB Guru Joined: 05/02/2015 Location: AustraliaPosts: 655 |

We learn something new every day and forget it the day after. We never did go back to Tassy and finish exploring it. Sadly. Peter(B) |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2975 |

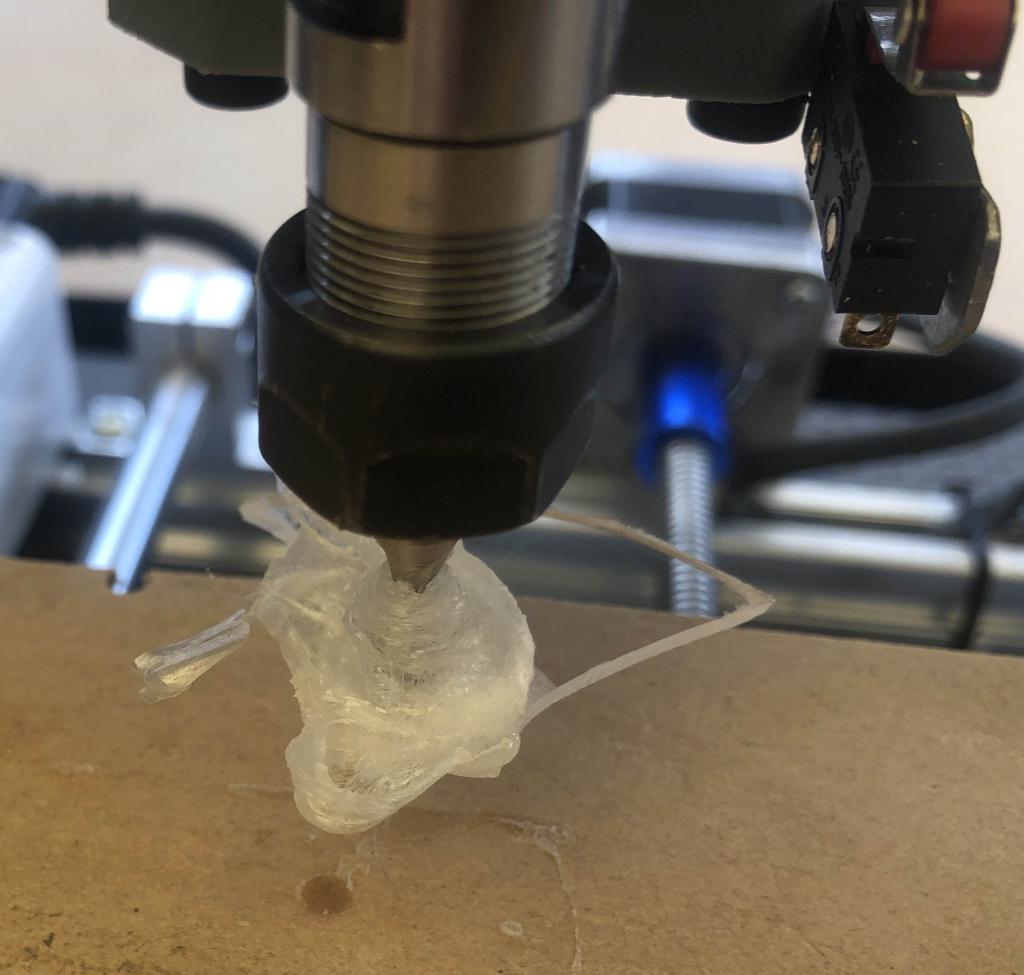

Hi All, I am definitely getting somewhere and learning along the way. Here is my latest attempt at a fascia panel, I need to get some wet and dry sand paper to polish it up but I am very happy with the result.  Now I tried cutting some acrylic for THWill, and boy did I learn something This was my first result.   But new cutters came (from China), supposedly for Acrylic 4 flute with really steep spiral flutes and the shavings flew off perfectly. This is the result  I am very pleased with them, They are now on the way to the UK for Tom to pick faults with.  To do those panels for Tom, I sped the X-Y up to 700 or 800 mm/s and took only 0.1mm depths (the melt job was 0.2mm depth and 200mm/s but a different but similar looking cutter) Anyway getting very close to being able to do what I want and for a cheap CNC Mill I am very pleased. Regards, Mick Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

| thwill Guru Joined: 16/09/2019 Location: United KingdomPosts: 4334 |

Hi Mick, They look very sweet, I guess we will soon found out if between us we managed to "measure 3 times and still cock it up". You don't want to have done too good a job or I may ask for more  . .Best wishes, Tom MMBasic for Linux, Game*Mite, CMM2 Welcome Tape, Creaky old text adventures |

||||

| Rickard5 Guru Joined: 31/03/2022 Location: United StatesPosts: 463 |

Mick You were asking about the House Clamp on my 3018 SPINDLE MOTOR, THE 3018 has a known problem if you over torque the SPINDLE MOUNT it cracks, so the hose clamp is a good solution until I get the Gumption to design a program to make an Aluminum one on the HASS Machine center/ Also I need to Make an Aluminum Y Axis Antibacklash Nut I may be Vulgar, but , while I'm poor, I'm Industrious, Honest, and trustworthy! I Know my Place |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2975 |

Hi Rickard5, That makes sense, when I built my unit I remember something about mounting the head upside down so the head is pushed up by the spring as opposed to pushed down (which means the cutter can move up against the spring). It made sense at the time. The 3018 is quite a difficult build to get right, before my career move in 1985 I was a toolmaker for nearly 10years and I found it difficult. The first thing I made was a waste board which I screwed to the platten, then i machined the wasteboard with a 20mm cutter at 0.1mm depths until it was entirely machined flat and level. Your platten looks the same as mine and is made from 2 pieces, in my case the levels were all over the place, I tried to level it with a dial gauge but it was obvious that the platten had warps, by screwing the wasteboard (12mm MDF) to the platten I could then end up with a flat and level (to the head) surface I ended up having to mill about 0.5 to 0.6mm to entirely clean the surface of my wasteboard. If yours is the same as mine I am happy to share the .nc files to make the board, although I might re-do the flattening one as I was over cautious about overlapping and speeds, so it took probably 30min per cut. I have always been a bit scared about hitting a clamp so I now use double sided tape pieces to hold most of my ‘projects’ to the waste board. I found these very nice, thin, strips that hold things very flat. >> Tape << The photo must show a child’s hand as these are only 45mm by 15mm each but they hold flat sheet very well. Regards, Mick Edited 2022-07-24 09:44 by bigmik Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |