|

|

Forum Index : Windmills : New Farm mill ready to go ~1KW.

| Author | Message | ||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 225 |

MacGyver, Well I think I've fixed the photo's either way the mill works great. Anthony. "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Good post Anthony. Are there any guy wires on the tower? Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

Nope, no guy wires whatsoever and shes pretty solid to boot. Had to be cow proof and short of fencing off 1/2 an acre for the guy ropes this was the only way. Cost is similar but we are a couple of metres shorter than a similarly priced guyed tower. The 3m3 of concrete was almost $500 and the pole (which is crap BTW) is a total of 6.75m tall $840 made of 5" Bore casing 5.65m bottom section and top section about 3.5m with an overlap of ~900mm plus the mount ontop for the turbine to sit in. Now for the next trip, safety system testing, will give the batts and mill a little belting, turn off the GTI, test dump 1 followed by pulling the fuse on the dump 1 to test dump 2, i'm thinking at 800W (have max 1600W in 400W increments) load for dump 2 (normaly both dumps will work together) should give it enough load (given isolated from the batts) to slow her down lots or grind her to a halt. Luck favours the well prepared |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Hi Karl, Looks like those extra anchor points you put in the concrete came in handy after all. Is that irrigated there, as hell it looks green for this time of year. Nice work, it looks very a tidy operation.

Pete. Sometimes it just works |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

no irrigation there but had three and a half inches of rain 10 days ago, prior to that it looked like a desert. sure made it real easy to hammer in the earth stake for the tower. Luck favours the well prepared |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

Oh and thanks again to Gordon and Phill for the Cap voltage doubler. 680uF caps back to back for each 100S stator, means cutin speed is basically startup speed. Takes about 3m/s to start, will keep rotating down to 1.5m/s and battery charging is happening with just under 3m/s wind. Funnily enough even with the anemometer just 80m away, there were times the anemometer was stopped and we were still putting in power and the opposite anemometer said 4m/s and yet out at the mill it was dead calm. Luck favours the well prepared |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

Thats why I bought it from eastcoast green energy. They reckon she's engineer certified with upto 2KW mill ontop. With supporting engineering I must assume he's calculated for a decent life. I do agree that the loads there would be decent, call it 60KG load at distance of 6.6m =3880nm of torque being applied here, that said, 5" bore casing is HEAVY stuff though being mild steel will deal with fatigue well. To be honest I'm more worried about the welded joint half way up the top mast, it has the welded on triangles for support but the welding is woeful quality. BTW now seen over 700W and we're only on day two! 12.5A at 57V BTW Greenbelt are you taking the piss being a Boeing Inspector? I used to do that! Luck favours the well prepared |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1631 |

Karl, My first tower was like that one pictured and it was installed right next to my shed which is only a 1/3rd of the way up the hill. One morning I looked up to the shed to see the top section of the tower bent about 45 degrees. It was 2" rural grade water pipe too. As other guys have said get some guys on there quickly just below the blades or be prepared to show the pic's of the bent tower.... |

||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 225 |

Karl, if you want a split collar with some eyes for guys give me a ring.I just need to know OD of pipe.You could tether them to the pig tails.Might help with suspect weld on pipe. Anthony. "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

I have faith in the engineering behind it. if not then eastcoast green energy will be fixing it for nicks. for now I'm concentrating on as much optimisation as I can before the move to Perth. Phill tells me I should go the 80S 2x7C and 100S delta combo as the overall power will be greater but I really like the shutdown which isn't as good with the smaller stators. Currently at 200rpm (not honking I know) It will shut down very quickly. Funnily -I got anthony to remove the copper wrapped around the terminals of the mill leads that was shorting it while we put it up, he claims he was getting a tickle even though the mill was barely turning.....wishful thinking perhaps  Luck favours the well prepared |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

KARLJ, Sorry Mate That's how it is in oz land,Take some and surrender some, but always share the Beer. I have a new picture of the folks down under after a google search for (piss take) I arrived at this conclusion,, I am Guilty as Charged, The desire for attention drives me to a continent half a world away and a willingness to deal with a country wide epidemic of mental illness. 1968 Boeing Everett, Washington, Largest single building in the world Nearly completed. The Mockup of the 747 jumbo jet airliner was transported from Renton Wa. to the new building this is where I worked until a lay off in 72 bad year here in the states. I and some friends stopped by the Boeing Museum of flight about two years ago to view the original piece of work. I pointed out a 1"dia. round patch in the skin of this aircraft that began as a 1/4" rivet hole drilled in the wrong place. odd that I remembered after all those years,but maybe not, It took engineering 3 weeks to decide how to fix this hole that had been worked on repeatedly by the riveter, they were fearful that the hole would be a starting point for skin cracks at altitude cabin pressure. this plane was never used by an air carrier. it was used to certify the model and in "Air shows" for promotional purposes. It had its own name, "CITY OF EVERETT"

A Google search will turn up Info for those interested. Over 1 hp already. Did you get a wind speed at that time and do you have a tac. on the rotor yet? would be interesting to find the torque those blades are producing. Karl , The preceding post was Meant to be a heads up that could possibly save your mill. 120 pounds jerking and thumping around with gyro forces many many times in the course of a year will harden the steel until it becomes brittle and then break like glass, should keep the flexing at minimum near the base. Stop by for a Beer and we'll talk about the rejection tag.

. EDIT; I had not read your latest post Good luck in Perth. Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Karl , Great to see all your preparation and time starting to pay divedends , as we do keep in touch by phone and email I know most of the details and have tried to give you as much help as I can . As you have just said above about having a 100s and 80s for the best all round combo on the dual stator , it does how ever depend on your wind . In my situation this combo is so close to the AxFx output in wind between 10 to 20 klm its not funny , as you know I trialed the 2 x100s and the daily output was dismal in my situation with the medium wind strengths , but the top end was good for 1.1kw+ in a blow. If you do get steady low to medium wind 50 ~ 70% in a 24hr period then you could be doing yourself out of a lot of lost power , for the sake of a 100w ~ 200w on the top end for approx eg 5~10% of the time , this is minimal to the power lost 90% of the time for total overall output figures . ( allow 20% loss in high wind for furling ,yawing , gusts and wind shifts ) The old story of the "tortise and the hare" Anyway its great to see a plan come together and I am hoping to see some great daily output figures posted .. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

MMM Greedy Here's my justification for the two 100S -people have run them in the past with no CAPS, output/cutin etc all OK then. SO What we have is an excellent blade profile, and a Big diameter for a 1KW mill, most 1KW mills are 2.7m diameter swept area of 5.72m2 and we are at ~7m2 a full 22% more swept area. A good site, with 80m+ to anything on the top of a big hill. Given that there is some power going into the batts at 3m/s i'm pretty happy- how many systems can claim that! Incidentally there would be 30% more turns in a 2x7C idea giving 2415 turns in half the stator vs 1848 in the whole 100S. Would it stand to reason that it would make cutin voltage 30% earlier than the 100S????? I must confess I'm waiting to see some 9-10m/s wind -if those windy days are few and far between then a swap is in order if not well....... bring it on! Incidentally will be going up Monday morning for the testing phase, should be easy with a forecast like this Monday Cloudy. A few showers. The chance of thunderstorms until evening. Winds south to southwesterly averaging 15 to 25 km/h. Tuesday Partly cloudy. A shower or two during the morning. Winds west to southwesterly averaging up to 35 km/h.

I like this too Please be aware -Wind gusts can be 40 percent stronger than the averages given here Strong wind warning for Victorian waters between Lakes Entrance and Point Hicks Winds: Northerly and increasing up to 30 knots early Sunday morning. Combined sea and swell: Up to 3 metres. Lakes is just up the road so plenty of potential for "a good blow" as Phill puts it Luck favours the well prepared |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

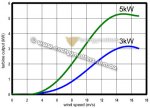

Here are some interesting figures from westwind turbines here is the output graph

Of interest here is the turbine is 3.7m diameter thus swept area of 10.75m2 or 1.5x the swept area of the 3m diameter Phillm Machine. Note almost nothing is happening at 4m/s at 6m/s we're only getting 280W. based on these figures i should be getting 186W at 6m/s this is just 3.3A given it has already made 3.65A in 5.5m/s I think i'm on a winner here. those blades absolutely kick ass in low wind. Luck favours the well prepared |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Karl I have enjoyed your adventure with the mill and am glad to see it is working out for you, Will you have time to do a performance log in the near future. I havnt done anything more with the VAWM as have been sick, hope to get back to it next month at the moment putting up a chinese 500 watt on the end of the shed lots of trees around so dont expect to much of it. Do you have another FP rotor as I only have one. I will use the two larger stators as the small one 60 I think is open circuit on one phase. All the best Bob Foolin Around |

||||

Trev Guru Joined: 15/07/2006 Location: AustraliaPosts: 676 |

Good on you Karl, good to see another mill flying and your results. Trev @ drivebynature.com |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

You need a data logger Karl so we can see some serious data from your mill. It would be nice to see some raw facts over time as we all have travelled this path with you and it be good to see the end results of actual data. Well i guess we will have too look towards Karl 2 mill in the Western winds for the data. Must say i am very happy for you to be getting some rewarding results form all your efforts you have put into the forum and your mill project.

Pete Sometimes it just works |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

Geez Bob, you're a day late... The last of my F&P gear went on Friday. I may have a spare hub at the farm, i'll certainly have a look. short of that now I'm going I can divulge my sources... Neil Maurice is the man, he calls himself "Hillsrecocentre" number is 1300 139 489 AH 9532 2506 email is neil.maurice@bigpond.com He was looking after me as I have bought about 30 of them from him, he's located in Moorabbin Vic. As for the open circuit on one phase on the 60, give it a good eyeball, perhaps it picked up on one of the other stators in transit and broke a wire. I'm no fan of the 60S myself, painful rewires, not as good output as the 80, not to mention the 100 BUT for a VAWT I think they have good promise as cut in is very low into 12 or 24V. Logging the data and live feed is beyond me in two ways, time and the lack of internet at the farm, I have followed the piclog with interest but at the end of the day just didnt get around to it. Perhaps the next one, where I'm next door to it with internet. When I get back Wednesday night i'll feed everyone with some data, dad tells me it was thumping 10-12A most of the day today so I'm hoping to see 20KW into the grid when I get there tomorrow arvo. This would be 4KW/day (somewhat optimistic but thats the kind of guy i am!) Luck favours the well prepared |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Karl No worries mate one will come up on ebay one day and Ill grab it. I decided not to rewire the rotors and use a open ended AC DC converter switch mode power supply on each phase converting to 27.5 volt to charge the batteries with a current limiter. These units are available @$45 each so is cheaper than building them, they work from 80 volts to 240 volts. Good to see your project working well you did a good job of documenting it and that encourages others to have a go. Hope your shift works well for you and as you say we are all as close as the internt. May the wind be with you. All the best Bob Foolin Around |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |