|

|

Forum Index : Microcontroller and PC projects : How to clean purchased boards.

| Page 1 of 2 |

|||||

| Author | Message | ||||

| Bizzie Senior Member Joined: 06/07/2014 Location: AustraliaPosts: 192 |

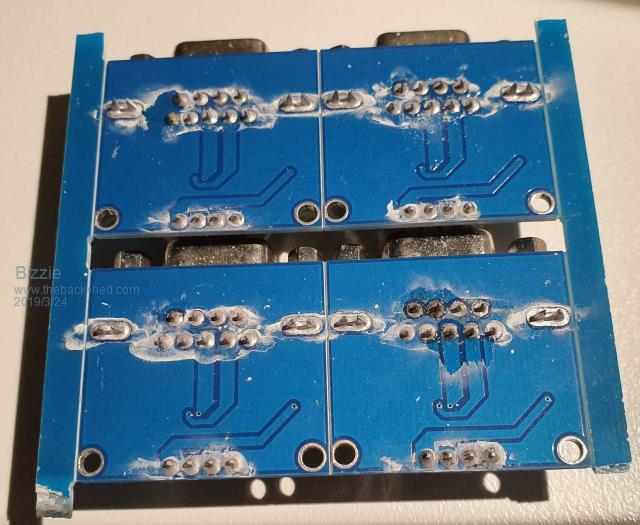

Hi all, Not sure this is the correct place for this post but I know I will find the best advice here. I purchased some "MAX3232 RS232 Serial Port To TTL Converter Module Female DB9 COM Serial MAX232" on ebay the units look OK until you turn over the circuit board.  What is the best way to clean them and stop the potential corrosion? Rob White |

||||

| CaptainBoing Guru Joined: 07/09/2016 Location: United KingdomPosts: 2171 |

I use a cotton (must not be man-made, and don't use those with plastic sticks) ball in snipe-nosed pliers dipped in DiChloroMethane (DCM) first - it will dissolve most things (you might try Acetone if you have no DCM). Scrub to remove all the crap. Do this is a well ventilated place, the DCM evaporates quickly and there is some suggestion the vapour can be carcinogenic (!) Then a wash in 50/50 IsoPropylAlcohol/Distilled Water and scrub with a nail brush. Leave to dry in an oven at 60C for two hours, or in the sunshine on an outside ledge (for those lucky enough to have it) for a day. works for me, but those boards are badly contaminated. When dry, consider dusting with a lacquer or penetrating oil (WD40) - dependent on where they are going after. my 2p |

||||

| paceman Guru Joined: 07/10/2011 Location: AustraliaPosts: 1329 |

I've received a few dirty ones and just scrub the dirty area with an old toothbrush and straight isopropyl alcohol. You can get the IPA at Bunnings in the paintshop section. Give it a good shake after you've scrubbed it and there's still IPA on it, it evaporates quickly. Then give it a bit of a blow and check how it looks. If it's still dirty repeat the process. Greg |

||||

| CYBERLAB Newbie Joined: 08/08/2017 Location: MexicoPosts: 26 |

Hi, I'm dedicated to repairing electronic cards, and for years I use good quality thinner, since it evaporates quickly and is not a driver, I use a toothbrush and that's it. If you are going to use them in an area with high humidity, say the coast, the bathroom with a clear varnish and finally a bath of WD40 |

||||

| Paul_L Guru Joined: 03/03/2016 Location: United StatesPosts: 769 |

Decades ago Tektronix had a standard method for repairing oscilloscopes ... they dunked them in soapy water in a bathtub! After a few hours soaking they treated them to a warm water shower or a second soak in clear water then a day or so in an oven at 120°F which would evaporate all of the water absorbed by the ceramic insulators. Water is the universal solvent and it evaporates completely in a warm oven. If there's any gunk left after a day at the spa you can resorts to solvents like alcohol, freon, lacquer thinner, DCM, MEK or the like but it usually won't be necessary. At Pan Am we found that organic stuff (burned flux) would often be trapped under a dipped layer of varnish. We would first strip the varnish with a solvent then proceed to the bathtub followed by the oven. It was always amazing to me how many filthy boards were passed by all the MIL spec quality control measures at Bendix, ITT Federal, Collins, Boeing, Douglas et al. Paul in NY |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2979 |

Hi Bizzie,All, Wow!, Those boards are disgraceful, I cant say I have ever bought any quite as bad as those before.. They look as though they have also been chewed by wild dogs...  That aside, all of the boards that I make for sale (or own use for that matter) I clean with a spray on flux remover and an old toothbrush.. It dissolves flux like magic.. It does feel sticky after its clean but dries quite well after 30min or so at room temp. I then pop them in little plastic bags before shipping. If you need to use them in `rough’ environs then you can spray with a Conformal Coat spray, I last used one that was an electrolube product about 30 years ago.. I assume RS Components or E14 would stock them.. There are MANY different types of Conformal coatings so chose the one best for your use Regards, Mick EDIT **** I would also consider resoldering those joints (remove the old solder first) as they could possibly be contaminated.. Mik Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9877 |

Isopropyl and an anti-static tooth-brush - spray, scrub, scrub, scrub, blow down with air-wick(compressed air in a can). Done. I don't know what the hell kind of solder some of these factories are using, but the residue from it it amazingly dirty. Smoke makes things work. When the smoke gets out, it stops! |

||||

| robert.rozee Guru Joined: 31/12/2012 Location: New ZealandPosts: 2492 |

they are using a lead-free, no-clean manufacturing process. supposedly the residue you see is electrically inert and water soluble. but from china who knows, and even if it is inert it can still provide a home for atmospheric contaminants in the field. btw, one thing to be careful of when reflowing lead-free solder is creating a mixture of leaded and lead-free. essentially you can end up with an unknown alloy that may have poor electrical and/or mechanical properties. i usually flood the joint with leaded solder, then remove everything with solderwick, finally resoldering with leaded solder. although not a perfect solution, it seems to work well. i hate lead-free solder. cheers, rob :-) |

||||

| Bizzie Senior Member Joined: 06/07/2014 Location: AustraliaPosts: 192 |

Thanks all for your replies Last time I buy on price ONLY! I paid $13.00 for ten. So far I have not been able to get a cleaned up one to work. Tried a loopback (DB9 pins 2&3) without success. A loopback of the TTL side is OK. Board powered from a lab power supply (5v). Will try Rob's method to resolder. I will also order some better (higher priced) ones. Rob White |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I once worked for a company that refurbished and repaired circuit boards, I learned rather a lot about that rather specialized art. The very first step was cleaning all the crap off the boards, so they came up like new. They used this amazing product from Electrolube (a UK company) called CTC carterclene. Its in a spray pressure can and comes out like a shaving foam. You spray that over everything and just let it sit for a few minutes, then give everything a scrub with a soft bristled brush. And finally rinse under running cold water. Then dry the board in an oven. Its a lot more than just detergent, it will not harm any components, but it cuts through oil, grease, wax, nasty stains, dirt, all the evil stuff that really sticks, but is non toxic, non corrosive and works like magic. A few years ago I tried to find out where to buy this stuff in Australia but could not find anyone that had it. That may have changed now, I really do not know. But I have tried many types of solvents, detergents, and cleaners over the years, but nothing even comes close to this stuff. If anyone can track it down, I would really like to know. Still have an empty can here, always kept it, had it for about ten years. Its that good. https://www.electrolube.com/products/maintenance-service-aids/detail.html?pid=ctc§ion=reiniger_und_diverse_andere_pr odukte?pid=ctc§ion=reiniger_und_diverse_andere_produkte// Cheers, Tony. |

||||

TassyJim Guru Joined: 07/08/2011 Location: AustraliaPosts: 6455 |

Element14 have it https://au.element14.com/electrolube/ctc400h/cleaner-foam-carterclene-ctc-lhd/dp/130473 I will try to remember to add it to my next order. Jim VK7JH MMedit |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Ah ! Great stuff, thanks Jim. It also works rather well on the front panels and knobs of ancient test equipment. Cheers, Tony. |

||||

| Volhout Guru Joined: 05/03/2018 Location: NetherlandsPosts: 5703 |

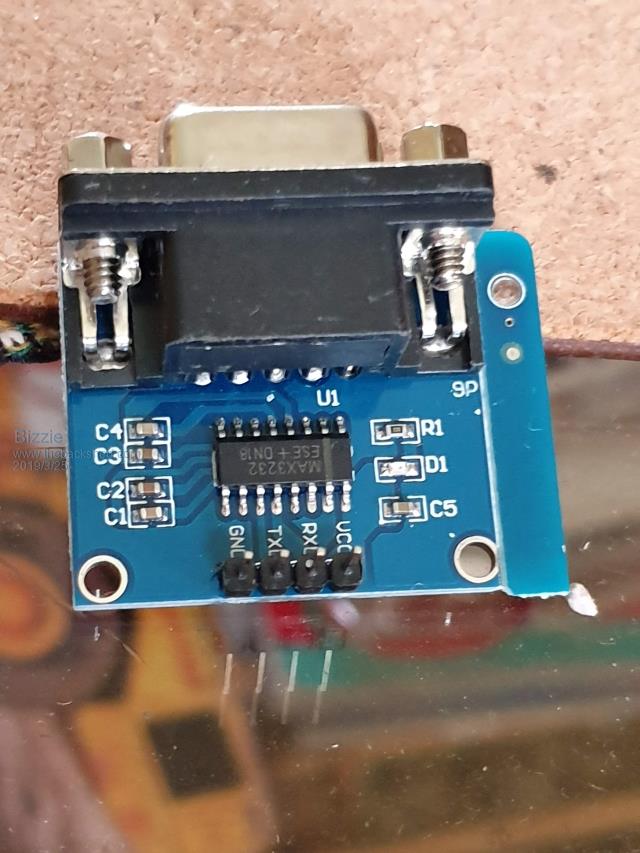

Looks like water damage, especially the one bottom right. This layout doen't seem very critical (no thin traces) you can take the risk of damaging the solder resist and but keep the copper on. So: toothbrush(electric?) and toothpaste. Give it a through rinse. Then (after drying) try to resolder the bad spots, especially if you expect internal contact to be bad (surface does not always show whats underneath). Then a bit of clear spraypaint as protective. But important question is: how does the other side look. Are the MAX232's in good shape, or is it just as bad there. I once had boards where corrosion at the SMT parts was so bad it was beyond repair. PicomiteVGA PETSCII ROBOTS |

||||

| Bizzie Senior Member Joined: 06/07/2014 Location: AustraliaPosts: 192 |

Here is an image of the other side, NOT the same one though.  Rob White |

||||

| CaptainBoing Guru Joined: 07/09/2016 Location: United KingdomPosts: 2171 |

Hmmm. that sounds a lot like SAFOAMCLEANER from CPC(Farnell) comes out like foam and the crud just lifts through it to form a scummy layer. The foam knocks back into a detergent-y liquid. Has a nice smell to. From looking at the link you sent, it has the same application suggestions (plastics etc) I used to use gallons of the stuff repairing statesman telephones for Spillers foods years ago (when it was economically better to repair than replace). They came in wet and covered in all sorts (mostly caked on bone-flour for petfood) and left looking like new and smelling a whole lot better. I used it on the PCB too - the statesman was a good phone for that environment because it was possible to dismantle the keypad and clean the contacts... a dusting of WD40 over the PCB to at least try and repel the moisture and good to go. https://cpc.farnell.com/servisol/100002000-400ml/servisol-foamcleanser-30-400ml/dp/SAFOAMCLEANSER |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2979 |

Hi Bizzie, Looking at the Datasheet The TXD pin is An Input. Ie. connects to the TX of say a mite. So you may have the TTL side pins reversed.. Regards, Mick Regards, Mick Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

It sounds like the exact same stuff from a different supplier, cheaper too. Anyhow its great for removing all kinds of crap and grunge without damaging anything. And it does leave a nice clean smell. Cheers, Tony. |

||||

| Bizzie Senior Member Joined: 06/07/2014 Location: AustraliaPosts: 192 |

Hi Mick and others, I will try reversing the pins. I was using a USB to TTL serial adaptor (Freetronics from Jaycar) with :- USB to serial Tx pn to TXD and USB to serial Rx pn to RXD and Pins 2 and 3 looped back on the DB9 With power (5v) from a lab supply. We have had a little rain here so it is on to the tractor today so will get back to this in a few days. Rob White |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9877 |

I can vouch for these modules - once clean. I have used a few of them, and they always seem to work. Mik is right though - the TXD is the INPUT to the module, and the RXD is the OUTPUT from the module. It's not a problem if you are using Dupont wires or something, but it would be a problem if you designed a PCB to host this module, and got the TXD and RXD around the wrong way! TXD...RXD....with respect to....which end was it now?(rhetorical)  Ever since they invented asynchronous serial, people have been confusing the TX and RX lines - I still do it regularly even after more then twenty years using plain old serial.  I much prefer the SPI labels. MISO and MOSI - no way to confuse those so long as you read it right!  Smoke makes things work. When the smoke gets out, it stops! |

||||

| Bizzie Senior Member Joined: 06/07/2014 Location: AustraliaPosts: 192 |

Found a little time! Jim's suggestion worked with loopback, thanks Jim. It also required me to change the leads to the probe I am using but that of course depends on wiring in the probe. Thanks all. Rob White |

||||

| Page 1 of 2 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |