|

|

Forum Index : Microcontroller and PC projects : Help needed with G-code for ILI9341

| Author | Message | ||||

| OA47 Guru Joined: 11/04/2012 Location: AustraliaPosts: 1036 |

I am trying to mill out a faceplate/surround for an ILI9341 display using one of those cheap Arduino controlled CNC Router/Laser engravers. I have written a short G-code program to cut out the viewing area, drill the mounting holes and recess the rest of the display area into the back of the faceplate. Here is a portion of the code that I cannot work out what I have done wrong. ; ROUTE OUT BACK AREA FOR REST OF DISPLAY (USING 1.4MM BIT) ; G00 X12 Y2 ;STARTING POINT M3 ;SPINDLE CLOCKWISE G1 Z-0.5 ;FIRST CUT -0.5mm G1 X12 Y54 ;ROUTE BACK AREA 1ST CUT G1 X80 Y54 G1 X80 Y2 G1 X11 Y2 G1 X11 Y55 G1 X81 Y55 G1 X81 Y1 G1 X10 Y1 G1 X10 Y56 G1 X82 Y56 G1 X82 Y0 G1 X9 Y0 G1 X9 Y56 G1 X8 Y56 G1 X8 Y0 G1 X7 Y0 G1 X7 Y56 G1 X6 Y56 G1 X6 Y0 ; M05 ;STOP SPINDLE ********* PROBLEM POINT *********** G1 Z3 ;Z AXIS RAISED TO CLEAR ; G00 X1 Y1 ;STARTING POINT G1 Z-1 ;2ND CUT -1mm G1 X12 Y54 ;ROUTE BACK AREA 2ND CUT G1 X80 Y54 G1 X80 Y2 G1 X11 Y2 When the router reaches the "PROBLEM POINT" it moves to home without raising the bit and proceeds to a diagonal point back at area of the viewing area cut. I am very confused on how the code is interpreted this way and I have been banging my head against the shed wall. If someone could point me to the error of my ways it would be immensely appreciated. OA47 |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5168 |

Have you removing the M05? Just wondering if it interprets this as a stop and go home instead of just a stop. You can leave the spindle running during a traverse. Or try the Z3 before M05 as a test. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| OA47 Guru Joined: 11/04/2012 Location: AustraliaPosts: 1036 |

Thanks for the reply Glenn but I have tried both of your suggestions and if I rem out the M05 then the problem moves to the Z3 command. It is as if I have reached the limit of commands in a sequence. I will try to break it up and see if that helps. OA47 |

||||

| OA47 Guru Joined: 11/04/2012 Location: AustraliaPosts: 1036 |

I think I have found the bug and I will give it another try. OA47 |

||||

TassyJim Guru Joined: 07/08/2011 Location: AustraliaPosts: 6455 |

I use CNCview.exe It saves a lot of discarded material Jim VK7JH MMedit |

||||

| Bizzie Senior Member Joined: 06/07/2014 Location: AustraliaPosts: 192 |

Is valid G code? I think it should be GO X1 Y1 ;STARTING POINT Rob White |

||||

| Justplayin Guru Joined: 31/01/2014 Location: United StatesPosts: 330 |

I don't know anything about G-code, but when I did a lookup of M05 and found that it could also be M5. Perhaps the "cheap Arduino" controller doesn't support the M05 variant. Just a thought. I am not a Mad Scientist... It makes me happy inventing new ways to take over the world!! |

||||

| grunto Newbie Joined: 07/01/2015 Location: AustraliaPosts: 15 |

I normally use Mach3 and your GCode interpreter may be different so take my observations with a grain of salt! I am assuming you are trying to cut a rectangle hole in the material? If so I have a couple of thoughts: 1. Your initial route is a strange tool path - you mill a rectangle at a depth of Z-0.5 and then go up and down the LHS multiple times, effectively cutting a pocket on the LHS (assuming the material is greater than 0.5mm thick). 2. You stop the spindle when the end mill is still in the material? You would normally retract before stopping a spindle (you normally wouldn't stop a spindle when traversing as it takes some time to spin up / down). 2. After you retract the spindle and return to the starting point you drop to a depth of Z-1 (without starting the spindle?) and then move from the starting point (X1 Y1) to X12 Y54 so you are going to either break the end mill or cut a diagonal line to that point - probably not what you intended? Not sure why the M05 is a problem - certainly Mach3 has no issue with it but as suggested in a previous post it probably isn't required. |

||||

| OA47 Guru Joined: 11/04/2012 Location: AustraliaPosts: 1036 |

Due to my very grey cells I had fallen for the same issue some time ago and had forgotten about it. The software that came with the 3 axis unit shows a 3D diagram of the paths that the router will take and as you manually step thru the program it highlights the path taken by that command. The issue is that it shows the diagonal path at the M05 command when in fact it is two steps further on at the G00 X1 Y1 which should be as in the first cut G00 X12 Y2 ;STARTING POINT and as mentioned the router should be restarted with an M3 ;SPINDLE CLOCKWISE. Once these corrections were made everything worked flawlessly and I am very happy with the end result having the display neatly recessed into the back of the casing so that it can be sealed and not have a deep edge where you need to use the touch feature. Thank you to all that helped. It is amazing when you get stumped on a problem for some time and just asking for help can alert you to the initial problem. I think my head would still be making dents in the shed walls if it wasn't for this great forum. OA47 |

||||

| matherp Guru Joined: 11/12/2012 Location: United KingdomPosts: 10965 |

Have a play with CAMBAM. I've used it for years and can highly recommend. Their demo version allows full functionality for a limited number of uses. It includes both the drawing capability and g-code generation |

||||

| zeitfest Guru Joined: 31/07/2019 Location: AustraliaPosts: 655 |

sounds great...  how about a photo to inspire us cnc newbies ? how about a photo to inspire us cnc newbies ?A library of gcode snips for the various displays, switches etc would be good. Hacking with a file after drilling holes etc is ok I guess but I tend to stuff up with crappy results. BTW can plastic panels be cut out ok, i am worried about melting edges. My last attempt at cutting thick polyethylene with a jigsaw was not good - the plastic melted and the cut edges welded together again during the cut !!!   |

||||

| OA47 Guru Joined: 11/04/2012 Location: AustraliaPosts: 1036 |

I will see what i can do over the next couple of days. I find slow down the revs and feed rate so that the plastic does not melt and still chips ok. OA47 |

||||

| OA47 Guru Joined: 11/04/2012 Location: AustraliaPosts: 1036 |

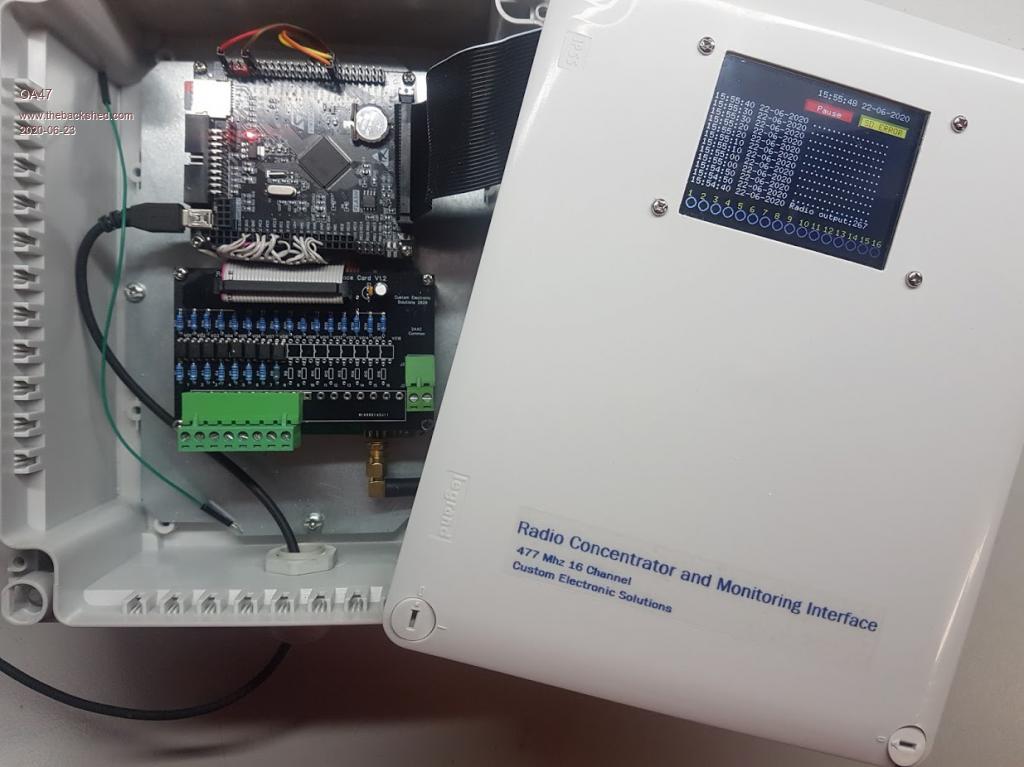

3.2" ILI9341  Earlier tests with 2.4 and 2.8 inch in front panels   OA47 |

||||

| zeitfest Guru Joined: 31/07/2019 Location: AustraliaPosts: 655 |

Nice ! You could probably sell them, the panel-type lcds often seem not to have any way of fixing to panels. |

||||

| vegipete Guru Joined: 29/01/2013 Location: CanadaPosts: 1160 |

Compressed air blasting at the cutter when machining plastic can be your friend. Except that it is noisy and sprays chips all over the place. Be cautious using any cutting fluid other than plain water, particularly with polycarbonate. Visit Vegipete's *Mite Library for cool programs. |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |