|

|

Forum Index : Microcontroller and PC projects : MCP4728 quad channel DAC

| Author | Message | ||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

Only bringing this up as a FYI. I did a search and found no mention of it but it's a cool 12 bit, I2C, 4-channel DAC. I have it doing rail-to-rail, +/-10v. The default settings are perfect for my application and so I have no library to post at this point. Maybe I can revisit when the heat is off.  |

||||

| hitsware2 Guru Joined: 03/08/2019 Location: United StatesPosts: 738 |

How are You getting + / - 10 V with a 5 V supply ?  my site |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

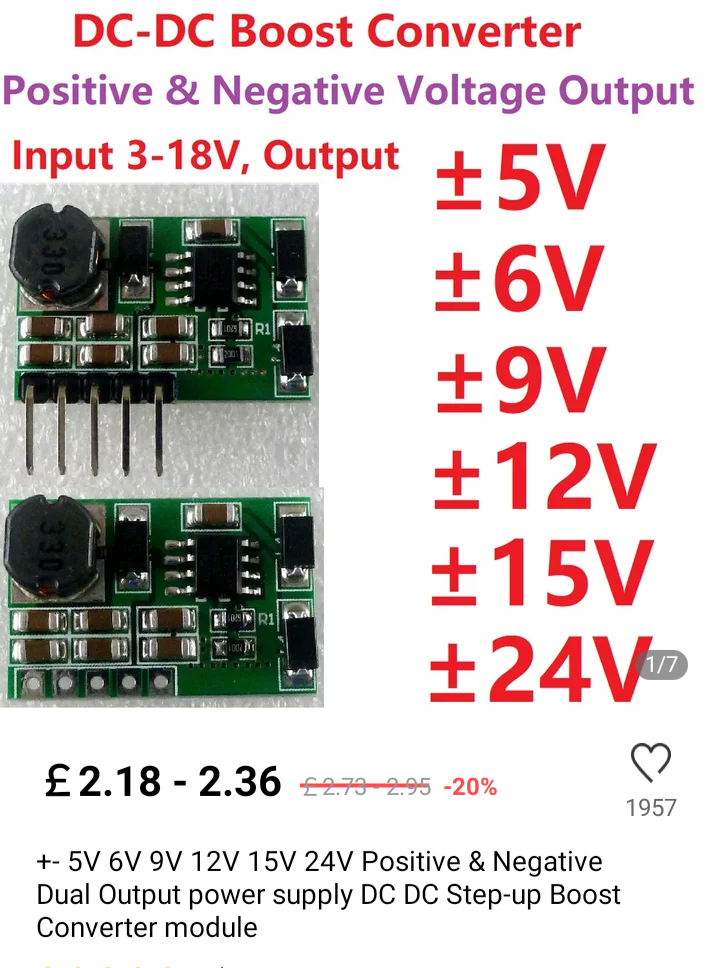

Yeah but from one of these devices which I am kinda impressed with:  |

||||

| vegipete Guru Joined: 29/01/2013 Location: CanadaPosts: 1160 |

Available here, for example. Visit Vegipete's *Mite Library for cool programs. |

||||

| Volhout Guru Joined: 05/03/2018 Location: NetherlandsPosts: 5703 |

Hi Tinine, What amplifier did you use? The device is 5V. Are you using the MCP to drive the switchmode convertor Vref pin ? Or are you powering the convertor with the MCP. For these cheap convertors, please understand that the +12V output has feedback, and will stay more or less accurate. The -12V is auxiliary voltage that more or less tracks the +12V, but it has no feedback. Therefore it will not be accurate. Volhout PicomiteVGA PETSCII ROBOTS |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

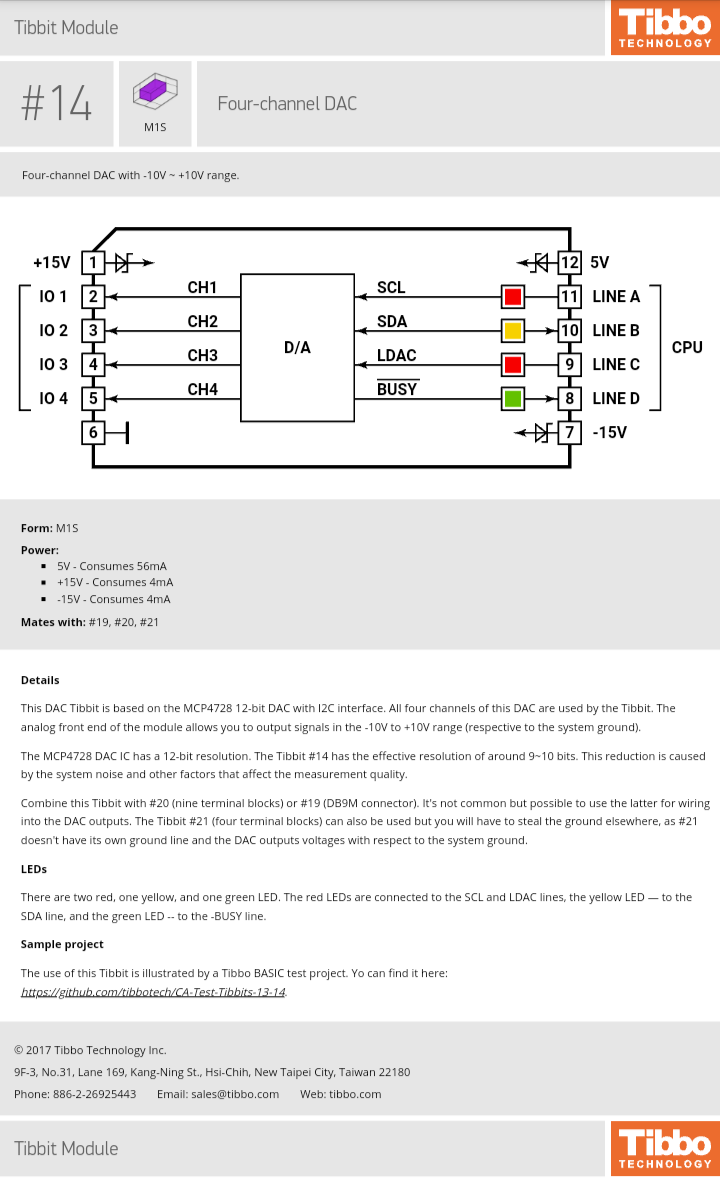

I should have mentioned that the 4728 is incorporated in a "Tibbit" module from tibbo.com.  Converter: Yes, I have found the same characteristics with other converters as well. It's not a problem (although I don't intend for this device to go any further than my proto board) because this is a closed-loop motion controller and my PID loop updates the DAC every 2ms to track the motion trajectory. Industrial servo drives accept a +/-10v motor command. This is my first actual DAC device as I normally LPF a PWM but I am up to 4 axes on a single MX170 and I need the PWMs for other purposes. |

||||

| Volhout Guru Joined: 05/03/2018 Location: NetherlandsPosts: 5703 |

Never heard of Tibbo, but they have a nice product portfolio. The stuff looks like an alternative for PLC's, more for development than industrial environment. Did not see prices, but if it is cheap and modular... Great. I am sure Mick (Gizmo) would design a nice MX170 board that can work with those modules if you ask him, so you can combine MMBasic with the variety of IO modules they offer. This is really the more professional breadboard stuff. Thanks for the hint. I may use it one day. PicomiteVGA PETSCII ROBOTS |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

Oh, I have a better idea  All will be revealed in due course. Yes, the modules are very inexpensive and will enable the MMBasic programmer to create a professional grade product. I have never bought in to the "industrial environment" thing; beige box PCs have been used for industrial controls for decades (I have just replaced one that I supplied 30 years ago). Many "ruggedised" PCs soon appeared but they weren't any more reliable but often included something proprietary that would lock you in to a single source, thus negating the whole point. It's all about signal conditioning such as opto-isolated I/O, etc.  |

||||

| Volhout Guru Joined: 05/03/2018 Location: NetherlandsPosts: 5703 |

A PC supplied 30 years ago .... Must have been running MSDOS. Yes, those machines where near indestructable, only the media interfaces (floppy, maybe harddisk) might have wanted attention, and the fan (in the power supply, not on the CPU at that time). But if it had been running 24/7 this kind of lifetime is possible. The fan would have stopped 10 years ago, but the power supply would have survived for another 10 years. It is hard to imagine, but there are still MSDOS applications running these days.... PicomiteVGA PETSCII ROBOTS |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

Yeah, MSDOS, puny CPU and 1MB RAM. Microtouch capacitive touchscreen and EGA (640 X 350) graphics. Hard drives always worried me so I created a RAM drive with the upper 384K RAM and stored my GUI screens there to avoid accessing the drive. This one in Ohio got a new drive and an ELO-Touch monitor in 2019 and it's good-as-new.  |

||||

| Volhout Guru Joined: 05/03/2018 Location: NetherlandsPosts: 5703 |

OK, this is for a wire bending machine (spring bending). Nostalgia ... the floppy and telephone(modem) symbols. You must be proud (and should be) that you created something 30 years back, that is still in use. Nowadays people talk about green, sustaining, the environment, but throw away 42% of their food, and every 2 years buy a new telephone. This is good example of sustainable.... PicomiteVGA PETSCII ROBOTS |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

I was the founder/owner of the #1 manufacturer of CNC tube benders in North America. Biggest clients were the auto industry. This is moi Edited 2021-03-23 22:05 by Tinine |

||||

| Volhout Guru Joined: 05/03/2018 Location: NetherlandsPosts: 5703 |

Wauw... Always knew it was good to be a nerd. These days even the girls realize that....;) Still active ? Or retired now ? PicomiteVGA PETSCII ROBOTS |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

Well I'm 61, going on 25  Dumped the stress and relocated to the UK. I'm only happy when working on controls/machines. I don't take holidays and I work 7 days/week. Sooo much opportunity out there but I flat refuse to hire any help...tired of baby sitting. To most people, CNC is G-codes and between 3 to 6 axes and off-the-shelf solutions for new controls are everywhere. In metal forming, we don't use G-code but we are still computer numerically controlling. 6 axes is child's play (my 20-axis machine is on YouTube). Point being is that; I have no competition whatsoever. What I am working on is a retrofit control system that is so darned simple that the client can do the physical installation and I will then connect from my location to debug the system and calibrate the servos, etc. This has been happening for a few years but always with a knowledgeable engineer on the other end. Not everyone has this facility and so I need to simplify further. I think I'm almost there  This is what is happening, all over the world:  Big name metal-forming CNC; Cybelec, Switzerland. User interface dead and now hobbling along with a PC screen/keyboard. The machine dies and the company is crippled. 250K and 6 months for a new machine...and this is only a baby model. I replace the whole thing with a ubiquitous Android tablet and my motion controller. Clients love this  |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |