|

|

Forum Index : Solar : Deciding if I should build this solar heater

| Author | Message | ||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 803 |

I had gone from brazing rods, to filler rods, to the TIG and backwards and forwards for weeks experimenting. My TIG is only DC, and you apparently need an AC TIG for aluminium. The crazy part is that when using the TIG to heat the tube I could get a beautiful melted line for several inches at a time ... but as soon as I tried to add rod, it just went horrible ... black, lumpy ... absolutely no flow at all. Was using gas. I ended up getting the best result with oxy, flux and filler rod. That was why I decided to try oxy on the final assembly ... but of course the 6mm thick heatsink is what really brought me undone. Just couldn't get it or keep it hot enough. I'll have to find a photo of some of my welds where I was joining 32mm tube with 2mm wall thickness with the oxy. I was starting to get some quite acceptable welds ... my biggest concern was that they seemed to end up with a fair bit of extra material ... which would have effected my airflow. Plus it was going to take me forever. Now that I have a bit of experience with the brazing rods, I can see plenty of uses for them. Cheers, Roger |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 803 |

Thanks very much, that is very kind of you. I never had a result anything like that while I was experimenting with the brazing rods ... that's why I wasn't going to bother with them. Actually what did sway me (apart from the shockingly bad first weld attempts) ... was watching a couple more youtube videos on the rods. Most of the videos demonstrating the rods focus on welding a hole punchd in the bottom of a drink can ... ... but I kept looking for a video on welding thick material. Once I watched that, I felt a lot more confident. Yeah, good point. I realised as I was welding, that if I do try to weld the other side ... to get it hot enough to braze ... it will also melt the top side again ... and I'll end up with the pipes all shifting or with "dry joints". That lump that ran down the pipe in the last photo ... I used a chisel to try and slice it off. After 4 or 5 sharp whacks, hitting upwards, the weld broke and the pipe went up through the angle. So I had to weld that one back in. But it held remarkably well considering how hard I was hitting it. I tried two different types from ebay ... and with those I found I was melting the aluminium before the rods would melt. Though to be fair, now that I understand how they are supposed to work, it may be worth another try. The third type I bought and have now just used are actually made in Australia. They are Ultrabond 3.2mm aluminium brazing rod ... and I bought them online from hampdon.com.au Go halfway down the page and they show them sold in lots of 5, 10 or 30. It was $49 for 30 rods plus freight ... see here You can also buy just one rod ... but $17.99!!! I kept thinking of something like that ... even thought about making something to crimp them in. Something like a pair of bolt cutters, so that when put it in the end of the pipe and close (or open) the handles ... it swells the tube just below the angle and above the angle to hold it in place. Yes, I saw them demo'd on a video and thought that might work ... would have allowed me to procrastinate for another week or three by ordering some ... but thought it was time to make some progress of some kind. Thanks Klaus. I haven't given up on welding aluminium, but I can certainly see me using these brazing rods again. You are right though about the heat ... you really need a big flame to heat a large area ... not an oxy type of flame with a tiny point of heat. I had bought a hose and fittings plus a burner for propane ... but when I went to assemble it to try it out today, I found one part was the wrong thread, so forget that. Fortunately a friend had loaned me his flame weeder and I just hooked it up to my bbq gas bottle and used that. It has 3 different ends ... 1", 2" and 3". The 1" seemed to work the best. Yes, if I was to do something like this again ... flaring sounds like a decent alternative. If I could flare it just below the angle and also above it ... it should be solid enough ... even if I ran a bead of silicone around it after to prevent any leaks. I do have a hydraulic crimping tool and I kept wondering if I could start with that and make some sort of tool to swell the pipe rather than compress it.  Thanks Aaron, and yes it was a massive heat soak. And to make it worse I had it clamped to a great thick walled length of square tubing which soaked up even more. Goodness ... I'd have been very happy to have that tidy a job. Though I can see why you might have a preference for no leaks over looks.  I've watched lots and lots of welding videos trying to work out how to do this ... and you guys amaze me how you just motor along, dipping the rod ... and come out with a beautiful finished product. Yes ... and in some ways it's a bit like soldering ... just a lot more heat! I'm glad you said that ... I don't feel so bad about not being able to get my TIG or oxy to work. Yes, I can understand that. The tubes were supposed to be virtually flush ... but somehow things shifted and I wasn't going to bother setting it all up again ... but it did cross my mind that it would be hard to get behind there Yep, I've finished the first side with 30 pipes, so just have to set it up again to do the other 30. Will be much easier second time around. Thanks for the encouragement Aaron, and everyone else as well.  Cheers, Roger |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 803 |

Yeah, that is what I've been doing ever since I've set up the differential controller ... it was just yesterday being so cold that made me think if I left it off for even 15 or 20 minutes it would have time to rise 20 or 30 degrees. I'm a bit concerned that once the big one is up and the outlet blows into the more lived area, that there may be some resistance to having 19 or 20 degree air blowing in ... and to wait just 15 minutes to avoid that, may still be a good idea.  I don't know either. Maybe I need to make some enquiries. That's the biggest drawback for me with our pool too ... the cold bbbbbreeze blowing past when you get out. Enclosing the pool area would fix that ... but I dare not suggest that to the wife otherwise that would be our next money soaking project. Yes, only way to go for peace of mind. We've got a heap of them all over the place, though they are the metal braided types ... but I guess they will eventually fail too. Very wise, great idea ... and again, good for peace of mind. Nice looking bit of gear, hope you get good use out of it. Yeah, I keep forgetting it's a reasonably decent temperature ... I think it's coz my wife's a cold fish and always complaining about being cold ... and wants it at 24+ !!!  Cheers, Roger |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Those brazing rods are really good, but like many things these days, there is a lot of fake crap out there. Plenty of horror stories on the internet about e-bay bargains. The proper rods melt at a temperature far lower than the melting point of aluminium. The fake rods have a higher melting point, and are probably just very expensive aluminium filler rods ! If you buy from a respectable tool or welding company, American, Australian, or European, they should be o/k. The ones I bought from e-bay were called "HTS-2000" and worked very well. I also have an ac/dc MIG plus argon, but its sometimes difficult to get right into very restricted corners with the arc. The arc tends to jump away from where you want it to go. On the other hand, the brazing rod can be poked exactly where you wish, into a very confined space, once the whole thing is sufficiently pre heated. The secret seems to be scrupulous surface prep using fresh new aluminium, and you cannot really go wrong. Cheers, Tony. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Dave, just found some time to view some of your burner videos. Great stuff, it all looks like jolly good fun. I once had a theory about Global Warming, but now I know who is really causing it  Cheers, Tony. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 803 |

Yes, exactly the conclusion I had come to. With the dud rods, I ended up with the aluminium so hot that I was poking holes through it with the rods as I was trying to make them melt. When I first tried the ultrabond rods from Hampdon.com.au ... it was obvious they were melting at a much lower temperature. I could see the effect just like shows on their youtube videos. Yes, that part is handy ... being able to poke it into any tight spots. I think what surprised me the most was when some ran through a gap ... a couple inches down the outside of a tube. I figured it would just break away ... like solder does when it drips down something ... but this stuff was bonded well and truly ... and it was way down onto a section that I hadn't cleaned. For me, the secret seems to be in getting the whole area really hot ... not just a square cm at a time like you do when using an oxy. I was blasting the whole area I wanted brazed ... melt some on ... heat some more ... then finish the job. I set up the second bank of 30 tubes today and had them all brazed in in under 2 hours. Very happy with how they turned out.   Cheers, Roger |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Very nice indeed Roger, that will be very strong too. As Dave says, the braze will completely fill the joint, no need to do the other side. Cheers, Tony. |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1577 |

Seemed like more fun before. Now it's a bit more of an effort but I have an agenda so I'll try to keep pushing them out and maybe I'll get more used to doing them again. I'd actually like to play with it more seriously. If I had funding as part of a university grant or something and access to equipment I wanted, I'm sure I could do something worth while with it. Just the same, had a lot of people over the years thank me for what I have shown that they have been able to apply. Lots of people melting metal and a few artists doing forge work, loads of people heating sheds, some putting burners in those outdoor furnaces, a few heating really large green house's, a guy in Argentina using an oil burner for grain drying and different things like that I never even knew existed. I'll do some Vids on running engines on oil too I think. That seems to have fallen from flavour of the month like it once was but still as viable as ever and there are a LOT of Myths in that game I could Correct. I'd like to do some solar Vids as well but that's a dry old subject to try and make entertaining but Guess I could give it a go. Must be true, I have been accused of that a load of times, some of them were even dead set serious! Used to have a lot of them saying I was destroying the planet with the emissions etc. Was fun when I'd tell them I was burning veg oil, the stuff all the greentards wanted to replace Diesel and Turbine fuel. Worst, most offensive thing you can say to these people is is point out facts they have in fact argued for themselves. I don't get many at all now. Like the safety zealots. Start making sport out of them and showing up their ignorance and they soon disappear. I want to do some vid on the veg heater but this week I have dedicated to shed clean up. Started on it this morning and only done about 90 min and probably not even a 10th of it and I'm stuffed. I am without doubt, the most disorganised, untidy, filthy, Grot of a Human being I know. Everyone says "My shed is a mess" but I have yet to see anyone match the crap and mess I make. I just can't help myself making ungodly disasters no matter how hard I try not to. I seriously wonder if it's possible to get Hypnotised to be tidy? Got off to a bad start here. Was in a rush to get out the other place so stuff got piled in and that's where it has stayed, with more crap Piled on top. I made that mistake in the last place. Moved loads of stuff that I put there 24 years earlier and hadn't touched till I picked up mainly to throw out when we were leaving. Thought we might only be there a year or 2 Initially. Boy, did that Idea go astray. I'm going to unpack one bay of the shed and put in the shelves and cupboards and benches I have had up there for ages so I have some space and places to put stuff. The rest of it is bulky and mainly stuff we stored when we got here. A lot needs to be thrown out. we are well established now, what we haven't used we won't so the local St. Vinnie's is in for another windfall. I'll even try to make space to put a nice big heater up there for winter. There is some furniture up there that is good but does not fit the decor here so I might make a cosy man cave corner to boot. Oh to dream! Having a decent work area again will at least be more conducive to fabricobbling and I might even be enthused to get a Drill press, a pipe bender, metal Band saw and even a lathe. I started on a Dirt Furnace the weekend so I might take some time out to do a vid of that through the week depending how I feel. |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1577 |

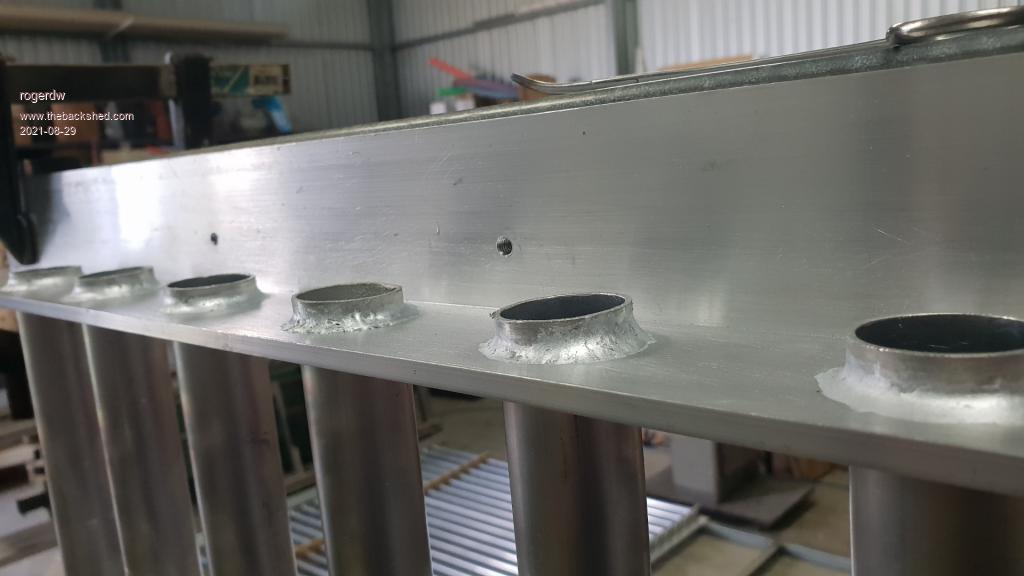

Looking at this pic on it's own with no insight, one Might be forgiven for thinking you were making a shark Cage, a flash set of bars for a Prison, The worlds largest towel heating rack or a ladder for fat, wide people with little feet. Doesn't look like my boots would fit through the gap in those rungs. The width might be appropriate though. Again, VERY neat and professional looking mate. Shame you have to hide it. Even though it's ally, It will have a fair bit of thermal Mass. What you were talking about before with the fan pushing 20o air, I guess you could just turn the thermo up so it moved the differential. If the start up is delayed, going to be pump ing warm air for a while with the energy stored in the setup that's for sure. Being ally the thole thing will hear up... Which may be something to think about with insulating it as well because the cold will also will really soak it the wrong way and you will bleed energy to atmosphere as well when it is warmer than the atmospheric temp. As Tony says, any input that's higher temp than what is inside is an improvement and will raise the temp. Perhaps it may be better to blow the air directly up so the warm air in the room is forced down to where you want it and circulated. It will feel most cold when directly hitting a person so if you reduce the felt air movement, may be better. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Don't want to derail Rogers thread, but Dave's burners have kind of sucked me in. I cannot see myself ever burning oil here, I have an unlimited supply of cheap clean trouble free natural gas. But thinking about how to build a small practical oil burner is an especially interesting problem, particularly how to automatically start such a burner up from dead stone cold. How about using a really small propane burner situated directly below the main oil burner manifold ? That could either use an even smaller continuous propane pilot light, or spark ignition to start the fun. Another way might be an electrically heated hot spot or glow plug. Car cigarette lighter kind of thing I suppose. That would vaporize the oil puddle in the upper oil burner sump, and when it begins to fume, it should eventually catch alight. Edited 2021-08-30 14:23 by Warpspeed Cheers, Tony. |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 584 |

Roger, I spotted something in your picture that brought back memories from way past. On that angle frame lies a burner lighter that looks exactly like the one I used when I started my apprenticeship in 1960! It looks like a good design does not need to change, yours looks too new to be of that vintage  |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1577 |

Any of your suggestions would work I think. Commercial burners spray the oil through some High voltage electrodes that arc to create the flame. One thing many have leveled at me is the fact I haven't done a push button start up. It's never really interested me. I can light one up and be getting heat out of it in Min if I have to but as I'm generaly running the things a while for melting or whatever, it's never really been a priority for me. If I was going to do it I think I would use a similar setup to what I did in some vids. preheat on gas and then change to oil. Flame sensor, couple of solenoids and a timer would be about all that was needed. I wouldn't have these as an on off on demand setup but rather a High low type of thing. Its really a matter of setting up for the desired application. They can throttle down far below the commercial burners. They are thought to be good at a 10:1 Turndown, Mine will do 20:1 just by backing off the fuel. Control the air and the fuel and you could I imagine do 50:1 without much problem. Could also go to a conventional spray setup only I'd use oil pressure rather than compressed air. As you said, Gas Pilot light, spray the oil, off we go. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 803 |

Thanks Tony. It certainly feels strong enough ... and will be good not having to pour all that heat into it again to do the other side. I imagine they are hard work and take a while to edit, but you've certainly put out a few already. Wow, I'm surprised ... but great goal. What sort of equipment did you have in mind? So many 'experts' seem to make everything they do look difficult and imply that you need to be someone special to do what they do ... whereas you talk it down and give the message that anyone can throw something together and make it work. I'll bet many people have had a go because of your encouragement ... who might never otherwise have felt confident enough. I get a lot of enjoyment from the comments as well as the videos. Clearly you have many fans and lots of respect in the oil burning community I'm pretty sure you could make it just as entertaining as the oil burning videos ... and as far as your subscribers go ... many of them won't have a clue about solar, they're oil burning fans ... so a complete new audience to educate about solar. I'm pretty sure my wife will tell you that I am the most disorganised and untidy grot around. She walks through my workshop and just rolls her eyes. Can't say I blame her.  Having said that, I had to do a big cleanup to make enough room to start this new heater ... and it sure felt good to walk in and see all that spare room after I had made some progress. I spent quite a bit on new shelves and they are so much nicer and more practical than all the rubbish and makeshift crap I've been using for years. Should have invested in them long ago. Regarding being hypnotised to be tidy ... I imagine it's possible. You've seen the size of my sheds ... but when we moved here, they were already full of stuff that the previous owner (and their friends) had left there. Lots of rubbish, but also lots of useful stuff. Big aluminium framed glass door off a local restaraunt, that is now the rear door for my electronics workshop, a pallet full of spare floor tiles and one of roof tiles ... a coolroom compressor unit, heaps of furniture ... so much stuff. Of course they were going to come and get it ... but it never happened ... so it really held us up as well. I went through all of it to make sure if I should throw it away or not ... and found a heap of birthday cards for their kids ... one still had a hundred dollar note inside it and another had a fifty. And even after I rang them and told them about it ... it was six months before they came and collected that ... and he lives less than a km away!!! There's still a table tennis table out there that he said he still wants ... probably his kids will turn up one day wanting it for their kids.  Great idea, if you're anything like me it will give you a real boost if you can just clear some space. I can't help you with the throwing away thing though ... I have real trouble with that. Yes, I'm sure it will help a lot and you'll be able to get a lot more done ... plus new toys have to be played with. They are a bit intimidating seeing them there in the shed ... will be nice to have it all finished and up on the roof. Thanks again. If nothing else, I'm learning some new skills so hopefully I can employ them elsewhere later as well. At least I have photos ... and some videos too now. Yeah, the differential controller does work very well ... though I am still kinda thinking it should start a little later ... let the heat build up a bit first ... then what does pump out is really worthwhile having. And it doesn't take long to build up either. Haha, yeah that's less than a year old. I bought a heap of bits from Bunnings to complete a basic oxy actylene setup. They must have been getting out of that range because they were about 40% off. I should have waited longer because I've seen some good s/h sets on marketplace since ... but the price was still pretty reasonable. At least I bought the bottles outright ... so I don't need to worry about rental, which makes a big difference ... and I can just zip down to bunno's when I run out and swap them over. My Dad bought an oxy actylene welder when I was a kid in the 60's and he had an igniter just like that as well ... so you're right, good design does not need to change. Cheers, Roger |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 803 |

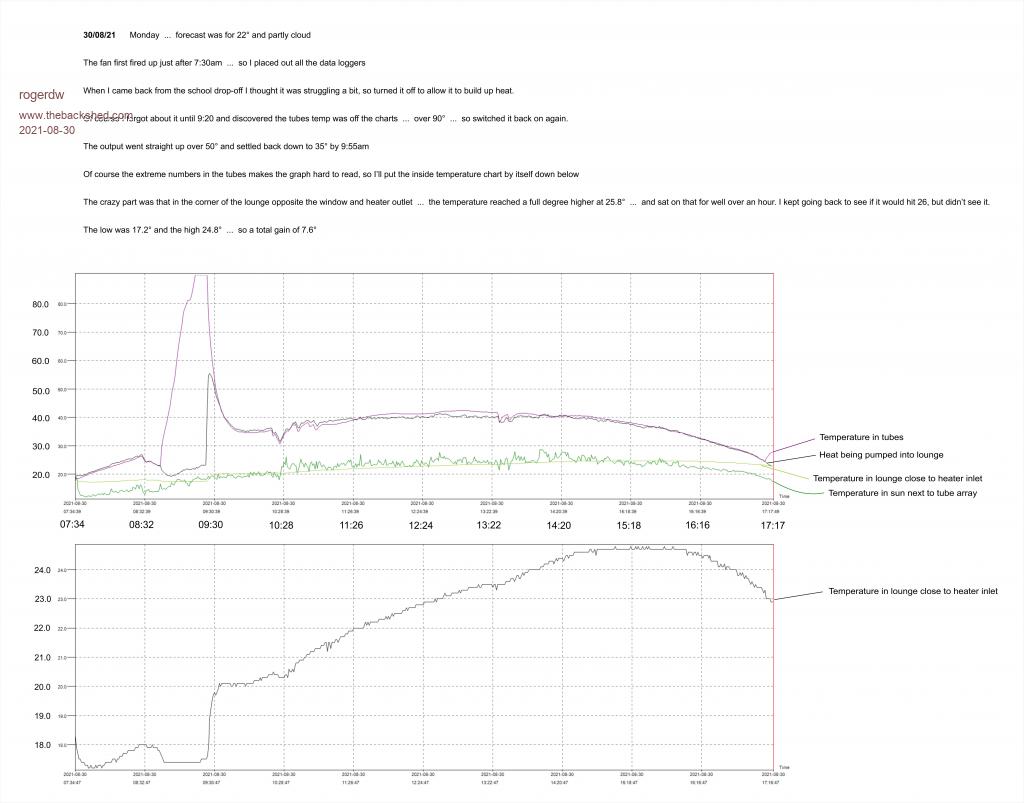

I haven't posted any charts lately so thought I'd throw one up. I did try turning it off this morning for a while to let it build up more heat, then promptly forgot to turn it back on. Certainly performed once I set it going again. I realise most of you would be turning on the air conditioner if you had it that hot!!  Cheers, Roger |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1577 |

It's more the motivation and ideas atm. The editing doesn't take that long hands on time anyway. The machine takes a while to format to YT standard. I have got pretty good at them now even though I haven't shot them till recently for so long. Being a shooter that cut his teeth on film where you got it right in camera, I tend to do that with the vids as well. I know if something isn't right so I delete it and re take. That' cuts down the editing a lot. Interesting comment, why are you surprised? I spose it's not just equipment but I'd like to have all the different sizes of Pipe and tube I'd like on hand so I could do what I wanted instead of using what I can find. That and the ability to cut and shape things would be good. I want to do an after burning Burner like a jet ending but it will require some tube bending that I don't have facility to do and would be too small for the muffler shop to handle. Might just have to make it big and go hard or go home. Having things like a metal fab workshop would allow me to build exactly how I dreampt it up though. I kept in mind what you said about that before and encouraged it especially in the last vid. Did have a LOT of people saying they were enthused to build one. They probably thought this Pelican can do it so anyone can. I used to get a bit annoyed about constantly being asked for " Plans". As I said many times, I didn't have any, I worked it out and I didn't have anything to go from . You want plans, you are looking at them in operation no less. I do like it when people make vids and say they were inspired or copying what they saw on my vids. A lot of them are shocked how well they work and how much power they get out of them. The oil burning " Community" I would say don't like me a lot. The metal forgers and blacksmiths don't like me because TBH I think they are a load of safety obsessed pussies and they don't seem to like anything that's not expensive and complicated. A lot of the people running veg oil didn't like me either because I shot down endless Myths and Folklore in that game with their over complication and then I realised I was undermining a lot of them that were selling different Products I was saying and proving weren't needed so I guess I was killing their racket with that. There is another guy that started out Friendly but has put KaKa on me many times in my absence and the style of my burners. He flat out lies and tells untruths about the style which is patently wrong. He Builds and sells spray Burners. I worked u out he probably doesn't like the forced air style because they aren't as easy and cheap to package up and send where as his being more compact are much cheaper. There is also a Turd In NZ that flat out puts crap on me and then rips off my designs, usually after disparaging them and claims it is his own and also sells them. Goes on and on about how powerful they are but I laugh when I see the fundamental mistakes he makes in copying them that renders them far less powerful than they could be. Big difference between ripping something off and replicating it as to actualy understanding how something works and what's needed to make it work best it can. It's the DIY'ers where my support is and the many that watch for entertainment. One is my sister in law. Clearly not of interest to her in a practical sense but she seems to love the vids which amazes me. She obviously watches them because she comments on little details she picks up which surprise me. As long as they can be entertaining and interesting I'm sure they will be OK. I just find it really hard to be funny now, especially on demand. Before things happened it was much easier. Now, I struggle but it is an essential element in keeping people interested. See, there is the proof right there I'm King grot. It's Impossible to WALK though my shed. You have to navigate the 10 Cm wide tracks through the stacked up crap. There is a lot of Non shed stuff, tools and my assorted crap to go though. I got one bay, the furniture and household stuff is the other 2 plus most of the Mezzanine. YES! I am tired and sore tonight having only cleared about 60% of one bay in there but seeing floor space feels very good. I will say a lot of it today was literally picking up one thing at a time. I'm down to where my engines are and Loads of stuff all on Milk crates so moving a lot in a little time will be easy tomorrow. I'll be able to get the tractor in there and I might take the engines and a lot of it up the little shed for the time being or throw it in the trailer. I'll put the forks on the 3 Point and throw a pallet or several on there and then back it in and stack the crates straight on there and then I can take a lot out at once. I hope to start getting the old Kitchen I saved in there tomorrow as my benches. The tops are 25mm thick and the cupboards are in good nick. I'll just have to see about the height. At my other place I built all the benches myself and measured them to fit. Other people would walk in and say why you build them so high but they were perfect for me. I can't help the vertically challenged having to reach up for everything and I'm well over backaches from leaning down all the time. Not sure how I'll be able to raise them if I have to but there is some big form work beams up the back I may be able to sit everything on. Yeah, I did too and now My father has shut down the yard and taken shelving out to put the tractors and Implements in, he has boat loads of it he's been trying to offload on me. It's all the good 50 YO metal stuff. You can Fill bays with alternators and starters being heavy and small and the shelving don't flinch. Don't know what the load rating is but he's put well over a ton in a single bay and not a problem. I think it's called Dexion shelving. I knocked up a frame on wheels so he could park the stump grinder on it and then wheel it around, mainly getting it off and on to line up. I put a shelf on each end where the grinder sits and they hold it just fine. Thing is around 340 Kg so they are pretty strong shelves. It would have wanted to be good stuff they didn't want back or I would have blown a fuse. I remember a guy bought a trommel dad had and left it there for 9 years. He came to pick it up earlier this year and I said that's long gone! He said what you mean, I paid for it. I said mate, the thing sat there so long and the weeds and things grew up in it till it collapsed from rusting away so it got loaded up in pieces and put in the skip bin. The guys said he wanted his money back. I said sure but the storage fees are going to be about 5X what you paid for it so you go get your money and we'll work out how much you owe us and for the disposal fee of having it taken away. Guy grumbled about how he'd paid for it and what was he going to do now? I said probably the same thing you have been doing without it the last 9 years! Moron. Yes, it already has been but I have barely scratched the surface. I can't help you with the throwing away thing though ... I have real trouble with that. Neighbour comes out this afternoon and sees all the stuff stacked in the driveway. He says you having a garage sale? I said no, just a long over due cleanup. He pointed to the compressor and welders and other stuff I had in one place and said how come all that's there? I said the way I work I have to strip it out to a clean swept floor and then I'll plan where everything is going to go and then re do it. He said you are the same as me, take it all out then you can pack it all in organised. I said I need to unpack it and pitch 90% of it to buggery not put it back including me so I don't make another ship Fight and end up in the same place. Last thing I want to do is put all the crap back in!! He said don't make me laugh, I just had open heart surgery you know and I don't want to split anything as I'm not fully healed. I said the only thing I'm going to split is my Britches and haemorrhoids carrying all that crap out of there. He started laughing again and said I'm going before you make me do myself a Mischeif. Will be nice to be able to work on my generators and engines inside out the sun and have a bench I haven't had for years. Need to get a new Vice as well but I think there are a couple in a load of stuff Dad gave me. Have to see if they are any good. There would be a sweet spot where the exposed part of the system was near max temp and heat soak. Up till that time the energy won't be lost. Let it go too long and you might loose a bit but then if you look at what you would loose in even 30 Min, it's not going to be significant to the over all kwh you get from the day. My father has a collection of them going back to when he was an apprentice and a draw full of those tip cleaning files as well. I still have my set I got when I was 19. I threw away all the hoses today and one gauge set. The hoses you could see the cords coming through and the gauges were stuffed as well. Kept all the handpieces and tips of course but not sure I'll use oxy again. Brazing would be handy now and then but I'm getting better with the New MIG and confident I can weld gas tight now with Care. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 803 |

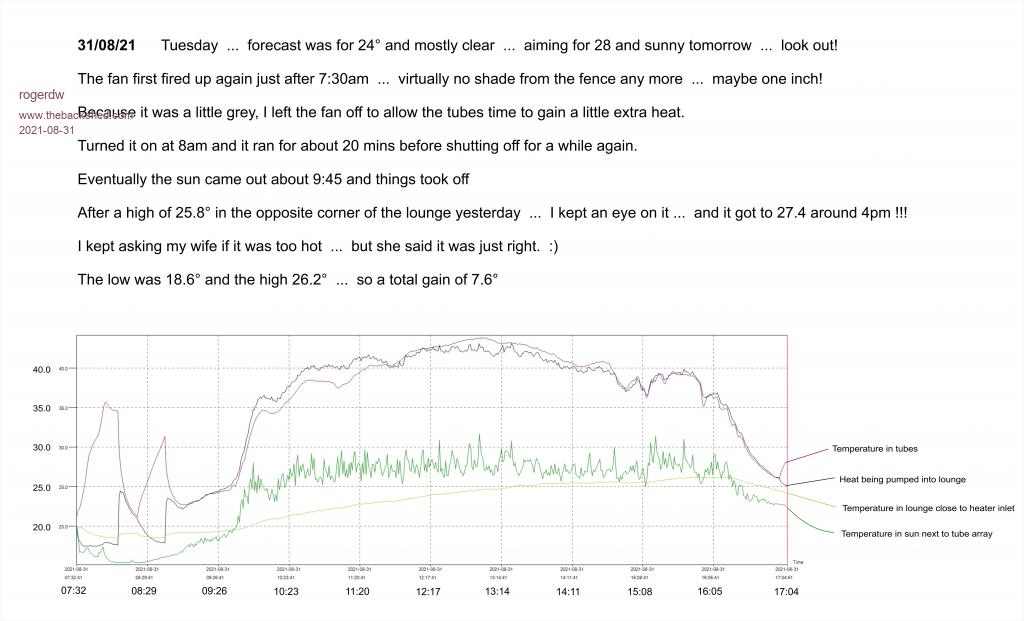

I think I'm gunna run out of time for using the big one this season ... it's warming up already. Forecast was for 24 today, 28 tomorrow and 32 on Thursday!!! ... though 17 on fri and sat. The lounge hit 27.4 today and the wife claims it was 'just right'.   Cheers, Roger |

||||

| Davo99 Guru Joined: 03/06/2019 Location: AustraliaPosts: 1577 |

I want to see what sort of gains you can make on thursday. Don't worry about being too hot, will be cool on Friday, rack up some thermal heat sinking. Crank that Baby up, we...... errr, YOU, need to see the data so you can set the New one up to keep your wife comfortable and happy which is the whole reason you are doing this and what you live for Right Mate.. Make sure you remind her of that, Frequently. Maybe you could experiment with rising the cut in point a bit. That's all you are doing in effect with turning the thing on later anyway. There is definitely an amount of capacitance in them so you probably aren't loosing any heat anyway. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

If its anything like Melbourne, its 28 degrees one day and 15 degrees the next. Probably time to start thinking about a room thermostat to tame the monster. Cheers, Tony. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 803 |

I can understand the motivation part ... I have that trouble all the time. For ideas, I'm sure your fans will provide an endless supply of suggestions if you ask ... and you can always ignore any silly ones. Very useful skill by the sounds. Haha ... it's more the idea of you mixing with university types. I can't imagine you putting up with any of their high and mighty attitudes when they think they know better. I'd love to see it though. Yeah, no substitute for tools and equipment ... even if you're like me and have no idea how to make them work half the time. I still have lots on my wish list too. That's awesome and there's no way of knowing where that might lead. I've been surprised at a lot of the questions too. I mean what else do they want ... you show them exactly what you're doing and explain it along the way ... and that it's not really all that critical for sizes etc ... I think it reinforces the fact that those of us here, really do have skills that a lot of other people don't have ... and of course vice versa in a lot of areas too. Sure, it's easier to copy something if you've seen a demonstration plus have heaps of diagrams and measurements ... but what you provide is certainly enough to help someone replicate your experiments. That's great, must feel good Haha, yeah fair enough. I should have said your subscribers and fans. I don't know the percentages ... but there seems a lot more favourable comments than unfavourable ... and I reckon if anyone was too unreasonable, your fans would get stuck into them.  That's awesomne ... and just goes to prove that for some people it's not even about the content ... they just enjoy your style of commentary and fun. You provide entertainment ... and people come back to find out what you're gunna say next. In a lot of ways, it might be that you just flat out say a lot of the things that they agree with and would love to say ... but don't have the courage to say in their own circles ... knowing how politically incorrect everything is now and how sensitive most people are. I know I wish I had the balls to say some of the stuff you say ... it's just that the mess might be hard to clean up ... though the older I get, the more game I'm becoming. Yes, understood ... but you still do have it. Ok, ok I'll have to concede that ... my pathways are at least 12cm wide.  Yep, and momentum is great too if you can keep plodding along. My biggest downfall is not thinking through where everything is going to go ... I need to plan ahead and have somewhere to put things. If there's not a spot for it ... it just gets dumped in the nearest empty space ... and then it's all downhill from there. Cool, gotta have spaces to work ... and better still if they are the right height to work at without wrecking your back. My main electronics bench was perfect for many years ... but now that my work is different, I find it maybe a smidgen too high ... but it's great for any stand up work. I have quite a bit of that too ... and was looking for more ... but I like the stuff I bought recently ... helped me get a lot of stuff organised and up off the floor. In some ways I wish I hadn't pushed them so hard to collect it ... I probably could have used more of it ... but it certainly held us up from getting organised. Yeah, well I can't talk, I still have a long way to go too ... but it's way better than 2 months ago. Sounds like a great goal, don't stop now. I'm still trying to work out that sweet spot. I'm trying to think of an analogy ... but it's a bit like if you're driving in 3rd and you floor it ... but don't have enough revs ... the thing gags and goes nowhere ... but if you have the revs up already and floor it ... it gets up and goes. Before I bought the new stuff from Bunnings I had picked up some s/h gear ... but it was old and the hoses looked sus. I might be a bit brash with some things ... but I'm not in any hurry to meet my maker, so I lashed out on new ones. I dunno ... aren't you going to go out and buy some aluminium brazing rods and work out how to use them?  Cheers, Roger |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 803 |

Yes, most definitely.  Though it's already backfired on me ... today she musta been feeling that warm she started asking about when I was gunna get the pool going  And now that you've mentioned it ... I am interested too to "see what she'll do" on Thursday if it really does make it to 32. Perhaps I'll fit the duct on and aim it at the floor for the next couple days ... I'm sure that limits the room temp a bit, which is fine ... and hopefully returns some of it when it cools down in the evenings. Yes, that is correct. I think the problem only really shows up when it's particularly cold ... if I have say 15 degrees inside and the fan comes on when tubes read 27 (12 above) ... it doesn't take long and the output drops ... ... and it doesn't turn off until it gets down to 20 degrees. Which even though it's 5 degrees warmer than the room, still feels cold if you get in its way. If it's 18 in the room, then it's quite a bit different. The reason I don't want to make the high temp setting (Hd) any higher than 12 degrees is because often the tubes will have quite useful energy still left in them ... but they struggle to get much more than 10 or so degrees above room temp ... so the fan doesn't come on to extract it. And once the room temp is up around 20 or so ... the low cut off is 25 (Ld at 5 degrees) ... and that is still ok to have pumping in if you are feeling that breeze. Yes, exactly. I have been amazed at how long it takes to remove some of that energy and get the temperature down again. Haha, yep. Though it's good that she's happy to have it get really hot because it must retain it a lot longer. I have to go back out to the workshop coz it's too hot for me ... but just happy to know we're saving lots of wood. Cheers, Roger |

||||