|

|

Forum Index : Other Stuff : Any concrete experts here?

| Page 1 of 2 |

|||||

| Author | Message | ||||

| Haxby Guru Joined: 07/07/2008 Location: AustraliaPosts: 418 |

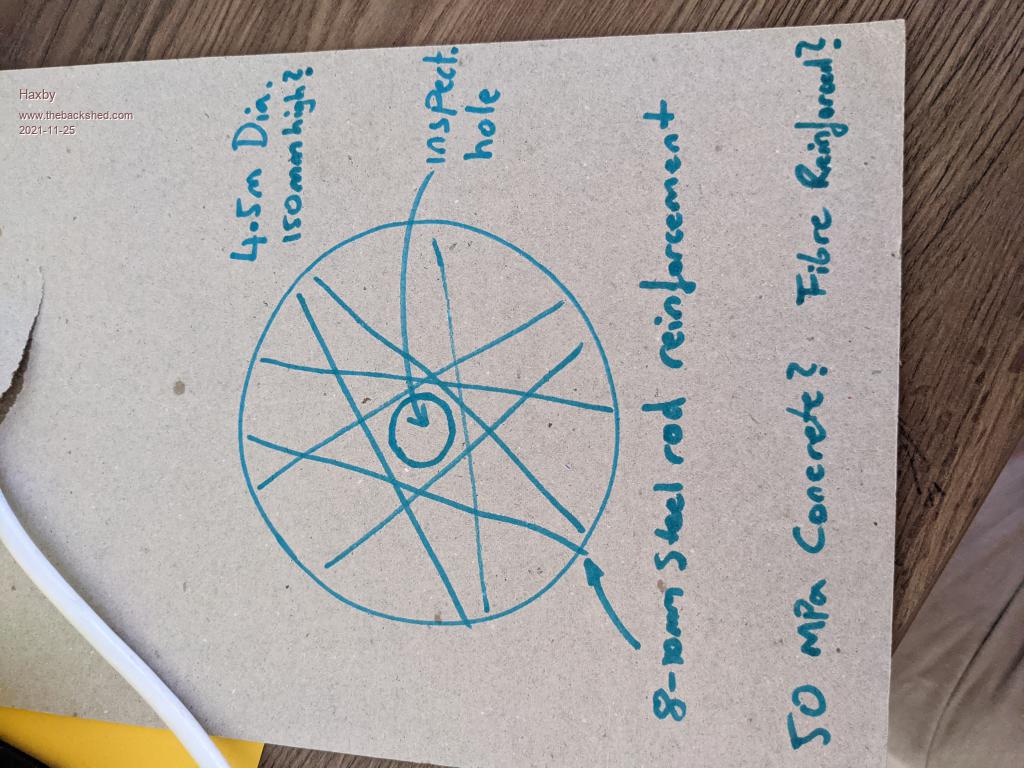

Hi all, Well this question definitely is for the "Other Stuff" category. I live down the end of a skinny driveway, and it's hard to reverse the car out onto the road. Also it's hard to turn the car around at the house end due to lack of room. The solution, of course, is a car turntable!!! Can't be too hard to build one, right?  So I bought a 1m diameter bearing, a 3 horsepower 3 phase motor and a VFD as a starting point.... The bearing is courtesy of a truck coupling. This is the bit that a Prime Mover truck connects it's trailer to. I'm told it's rated for 40 tonne, so it should be plenty. It spins freely by hand. It comes on a 12mm steel base, and is very very heavy.  Now my original thoughts were to weld up a steel platform on top of this, and have the traditional castor wheels on the outside circumference.... but then I thought it might just be easier to form out and pour a reinforced circular concrete slab directly on top of the bearing, with a circular centre void to be able to grease up the bearing periodically. No outer castors at all, so the concrete would have to withstand a cantilever force as the car drives on top of the slab. So my question for the group is whether there are any concrete experts here that could advise on what type of concrete to use, and what reinforcing to use. Just off the top of my head, I'm thinking 8mm steel rods running at a tangent to the centre inspection hole. All thoughts appreciated!  |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1206 |

OK firstly a 4.5M diameter by .15 thick slab will break on the first test if a heavyduty rio cage isn't built and 150mm is too thin to take the load of a small car let alone a 4WD. One would be better served fabricating up a steel turn table and heayduty one at that and outer caster would be needed. A steel fabrication mob could roll some PFC to the required diameter for the outer caster/rollers which would support the weight. but with the cost of doing all this it would be much cheaper just to do some earth works and concrete in a round about so the cars can turn around |

||||

| greybeard Senior Member Joined: 04/01/2010 Location: AustraliaPosts: 157 |

Handbrake turn perhaps?  |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 581 |

Have you considered backing into your driveway? At my place I do just that. The ute's rear view camera can see the tow ball. All I need to do is to align that with the central expansion gap in the concrete of the driveway and proceed to back through a gate, down a curved driveway and into my garage. The car is then always ready to drive straight out and I have a good view of the road once past the gate. Could not see the road if I was backing out until the car's rear end is way onto the road. |

||||

| Haxby Guru Joined: 07/07/2008 Location: AustraliaPosts: 418 |

There is a sharp bend in the driveway that is a bit difficult to navigate while reversing and there is not enough space to turn around without doing about 3 to 5 maneuvers once you are in, so the turntable is an intriguing solution. And since I have the big bearing, I feel that the solution is to build a platform on it, either with traditional steel pieces or with some other material. The appeal of concrete would be that it could be formed and poured in-situ. I just have no experience in working out how thick it should be or if there are other tricks of the trade such as reinforcing with glass fibre etc. Another thought was to form the concrete mould with some thicker ribs, and a thicker circumference, but again I don't know how to start modelling the dimensions that I need. I can calculate steel beam deflection but concrete is a mystery to me. The other appeal of concrete is that I could cover the top with bluestone tiles. That's something I couldn't do with a steel platform. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I have seen Haxby's horror driveway, and its the stuff of nightmares. The electric turntable idea is genius and a perfect solution. Back in ancient times, every local garage had a classic single post in ground hydraulic car lift that you could drive straight on to. Something basically like this:  Haxby's turntabe is large enough and strong enough to support something like that without needing casters at the corners. I would just build a heavy steel H frame or X frame along similar lines to the above. On top could be a couple of standard car ramps or a round carousel. My preference would be for wooden decking that could be removed. Concrete would be too permanent and immovable if you ever needed to get at the turntable.  Cheers, Tony. |

||||

| Haxby Guru Joined: 07/07/2008 Location: AustraliaPosts: 418 |

Timber is an option. Do you mean with a steel subframe? Or maybe I can get away with 2 timber layers perpendicular to each other... |

||||

| Haxby Guru Joined: 07/07/2008 Location: AustraliaPosts: 418 |

I wonder if 2 layers of 50x200mm sleepers would work. The platform would flex as the car drives up but once in the centre would be well supported by the bearing... |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I would use steel I beams bolted to the turntable. Then fairly close spaced wooden bearers bolted on top of the steel, with brass or stainless steel bolts. Conventional decking secured with brass screws on top. There would need to be slight gaps between the planks to allow for swelling and contraction of the wood at different times of year, just conventional decking practice. The whole thing could sit in a circular pit, a poured slab with a few courses of brick around the periphery. Its going to fill up with storm water, dead leaves and wind blown rubbish, so it will need to be connected to an easily cleanable sump, and storm water drain. At least that is how I see it.... Cheers, Tony. |

||||

| Haxby Guru Joined: 07/07/2008 Location: AustraliaPosts: 418 |

An X frame might have to be the solution as I'd prefer the car to be able to approach at any angle.... Sounds like a steel frame is inevitable no matter what. I was hoping for a different solution as I hear that it's easy for these types of frame welds to warp the entire circle as each weld expands and contracts. Maybe I can bolt them all together. Anyway it's all good food for thought. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

If you want to build an x frame, it can have more than four legs. Maybe six ? If you use I beams, they all radiate from the centre, bolted to top and bottom gusset plates. Upper plate is in tension, lower plate in compression. The further apart they are, the stiffer the whole thing will be.  Cheers, Tony. |

||||

| CaptainBoing Guru Joined: 07/09/2016 Location: United KingdomPosts: 1985 |

my local car wash has a turntable... just steel checker plate on the top but it has "sagged" - dips in the bed between the ribs, over the years with the constant weight. Its a steel "spider web" underneath with rollers on the circumference. could do with more ribs to counteract the sagging A bit like the one in the middle here but car sized. this PDF off their website might give you some ideas Spin-It-Driveway-Car-Turntables-2021-brochure-1.zip This is a nice project you got going... I would love to work on the control system... ring gear or spindle driven? sensing the stops, soft approach, monitoring current draw to detect jams etc... what fun and a practical result. Nice! h Edited 2021-11-26 19:01 by CaptainBoing |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 581 |

Agree with the above message, its an interesting project. I would consider using your turntable *and* the rollers around the circumference. This would allow a lighter steel frame and you need not worry about parking the car exactly in the center every time to balance the turntable load. I see the commercial unit uses the same 1/2hp motor for all their turntables. Perhaps using a toothed belt for the drive? Those rollers are available at places that specialise at castors & wheels. I used 4 of them for a special movable beam loader to get my heavy lathe into place in the workshop. |

||||

| johnmc Senior Member Joined: 21/01/2011 Location: AustraliaPosts: 282 |

Good day All The modern rotary dairy, use a water bed with a floating rotary table , may be this principle could be applied, water displaces 6 1/4 lbs per cubic ft. Cheer's john johnmc |

||||

| johnmc Senior Member Joined: 21/01/2011 Location: AustraliaPosts: 282 |

Error in above post 62 1/4 lb per cubic ft, or in metric 1000kg per meter cubed  cheers john johnmc |

||||

| Haxby Guru Joined: 07/07/2008 Location: AustraliaPosts: 418 |

CaptainBoing: the control system will be very simple. The accelerate, decelerate and max velocity will be set in the VFD and the user will have to hold down the clockwise or counterclockwise button on the remote while using it. No end stops. There won't be any obstacle sensors, but overcurrent I believe can be programmed into the VFD too. The idea is that you're only operating it just after you have driven into it. I'm not sure how the motor will connect to the bearing yet... I'm thinking a store bought gearbox with a rubber wheel that pushes against the inside of the bearing.... Will have to think that through. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I rather like Klaus's idea of the toothed belt. The belt could go around the outside of the bearing, the surface can be smooth and it won't slip because there will be a very large belt contact area. A toothed pinion on the motor shaft can then engage the teeth in the belt. Cheers, Tony. |

||||

| phil99 Guru Joined: 11/02/2018 Location: AustraliaPosts: 1776 |

What speed is your motor? If its 4 pole = 1440rpm and the turntable is to do say 2rpm you need a reduction of about 700:1. If the motor pulley is 20mm then the turntable "pulley" will be 14000mm = 14m! To reduce the speed sufficiently with a VSD to use the bearing as a pulley the motor might not have enough torque and its fan would provide little cooling. A gear box or second belt reduction may be needed. |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 961 |

It shouldn't be too hard to find an old 3phase motor and gearbox, perhaps at a scrapyard or dump, they were used in conveyor systems, sometimes belt drive or quite often had a large sprocket for a decent size chain drive, should work with the VFD. Cheers Aaron Off The Grid |

||||

| CaptainBoing Guru Joined: 07/09/2016 Location: United KingdomPosts: 1985 |

if you drive onto the outside ring it will be a big reduction in revs/min. Depends how much of a circle you are gonna get. One of the pictures in that PDF shows a "service" hatch on the outside of the turntable - could hide a motor in there, vertical motor with small rubber wheel on the spindle driving directly onto the steel. That would mean your centre bearing needs zero modification and all the motor etc is really easy to get to. |

||||

| Page 1 of 2 |

|||||