|

|

Forum Index : Microcontroller and PC projects : Galvanic isolation...is it overplayed?

| Author | Message | ||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

The Arduino Portenta Machine Controller (available at Mouser, Farnell, etc.) accepts the industry-standard 24v DC input levels via voltage dividers only. Of course, inputs from external equipment would require opto-couplers to avoid tying grounds together. Manual attached. Portenta Machine Controller.pdf |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8564 |

I don't think there are many controllers that have galvanic isolation on all inputs as standard (and very rarely on analogue inputs at all). At best you seem to get blocks of digital inputs isolated (typically 4 - although AC inputs are quite often isolated). If you take it to its logical conclusion then everything should be galvanically isolated, which is just stupid. You only fit isolators where they are needed 'cos the darn things cost! A lot of external equipment is powered by its own mains transformer/SMPS and is therefore galvanically isolated by default. The "proper" PCs are (and always have been) modular so you can fit isolated or non-isolated input and output modules to the bus. They also cost a fortune. Of course, this device has some *huge* failings! It requires learning a nasty version of C and using the Arduino IDE, both of which are utterly vile. Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| Volhout Guru Joined: 05/03/2018 Location: NetherlandsPosts: 5703 |

The issue with galvanic isolation is simple. I design hardware for companies like Siemens and ABB, and they are strict about it. It is prescribed in standards. They manufacture equipment that is pretty fault resilient, and installers dont have to wory about details like that. No hidden ground loops, no high currents running throug common pins in I/O cards. In case of a single failure in the installation, in most cases no further damage is done. They sell their modules at premiym price, so the hardware cost can be absorbed. If you know your system, and accept that some single failures damage larger parrs of your system (i.e mains touching 5V inputs) you can tune the isolation to what you need. Sometimes you can even work without double insulation. But you need to make a propper ground and power plan to see where you need it, an where not. Volhout One of the tests that you can perform to see is a usb connention for keyboard or pc. That needs to widthstand 8kv contact discharge (ESD). Even with grounding close to the usb connector, this may be insufficient. Since USB is difficult to isolate and expensive. Somtimes the complete CPU subsystem is isolated including the USB. Edited 2022-01-01 19:22 by Volhout PicomiteVGA PETSCII ROBOTS |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

@Mixtel90 Yeah, it's a lousy design as well  Programming for Arduino/ESP32 etc can be handled in BASIC using B4R I have been using B4A (Android) for 10+ years, now. |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8564 |

It was the old Siemens PCs that I was thinking about. Was it the S500? The "little" one anyway. Built like a tank. Lovely stuff! I fully agree on the power routing. We used to do quite a lot of stuff for power generation (on a small scale - most sets were under 2MW). Lots of 24v taken from the engine batteries there. A lot of isolation used to be done using simple plug-in relays - not because they are technically the best choice, but because if a set doesn't start you have to be able to fix it or isolate it fast - and you might be in a desert with the closest souk 50 miles away and no guarantee of any spares. Just pull a relay or two. Once the electronic engine controllers arrived it became a bit easier. Those often ran from a common station battery which was cleaner and more stable, but alarms etc were still signalled out on clean contacts. I never got into the fancy HMI stuff, networks etc. We did do a lot of field wiring for sensors, solenoid valves, 3-port valves etc. though as we were basically an electrical contracting firm that did a bit of control and switching gear. Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8564 |

@Tinine Eh? Not a promising start. lol Have you ever played with Ladder programming on the PIC chip? It's rather old now and rather limited, but it's far closer to proper old PLC programming. :) Edited 2022-01-01 19:53 by Mixtel90 Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

@Mixtel90 I might just have a play with that  Although I despise ladder-logic  My last year as an apprentice at Taylec (Ulnes Walton), we started using the Modicon. Myself and another apprentice picked-up on it immediately. The so-called electricians at that place were nothing but point-point wiring monkeys, no-idea regarding the logic. I was totally underwhelmed because, just like the relay drawings, one couldn't visualise the sequence flow. I quickly took a job with Addison/Pressbend on Walton Summit who were just starting to manufacture CNC Tube Benders.... MUCH more fun  Funnily enough, fast forward a few years and I was chatting with someone on Compuserve regarding my PC-based controllers and out-of-nowhere, Dick Morley jumps in and proceeds to tear me a new one. DM created the Modicon and is regarded the "father" of the PLC. I didn't take any of his cr@p and look at what happened...Most high-end controllers today have a PC on the front-end at least. DM: "industry needs Mack trucks, not Ferraris" Whatever!  |

||||

| phil99 Guru Joined: 11/02/2018 Location: AustraliaPosts: 3015 |

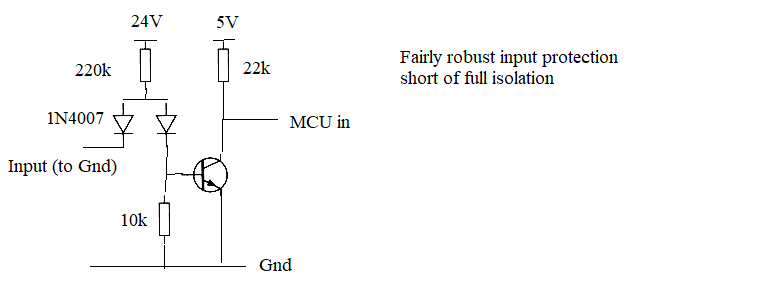

|

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8564 |

I used to like relay ladder programming - probably because pre-PLC we did a lot of hard-wired relay stuff so visualising relays was no problem. In fact, the main difference was that we could have any number of any sort of contacts on a relay. :) The first PLC I used was a Merlin Gerin. They were early ones, where the CPU was a load of logic boards in a horizontal stack. IO boards fitted into the rack below it. I don't think it used a microprocessor in that version, there was certainly a lot of (hot) logic. It was programmed in a sort of machine code. My favourite had to be the Crouzet (or Omron or Telemecanique but several makes were available) "intelligent relays", with typically 8in and 4out in a small unit. A nice easy drag-n-drop logic block programming language. Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| vegipete Guru Joined: 29/01/2013 Location: CanadaPosts: 1160 |

I always quite enjoyed ladder logic programming. Perhaps my first contact with it was helping a friend alter the functioning of an ancient gear hobbing machine. This was truly done with physical relays and wires. Next came actual PLCs, which were easy enough when you accept that a ladder logic program is more or less a circuit diagram. Yeah, maybe you gloss over the sequential execution of a PLC compared to the parallel nature of actual relays, but most of the time and with a bit of care that can be ignored. My most recent PLC project was the controls for a custom sawing/drilling machine. Long lengths of material were to be chopped into short pieces with 4 mounting holes drilled in each. All the clamps, material feed mechanisms, the saw, the drills and the material sensing had to be automated. I was pleased with my self when I managed to include, in the ladder logic, the ability to single step the entire cycle, to make trouble shooting easier. Sure, something like a Micromite could have been programmed to do the job, but that would involve a lot of futzing around to package it and harden it for the shop floor and the knuckle-dragging maintenance crew. We chose Click series PLCs from Automation Direct - low cost and replacements available fast. Relay contacts for the most part, providing more than enough isolation. Solid state relays are the other goto for simple isolation. We did have an interesting one with a computer controlled machine that measured cans. It needed to be easily portable so we used conveyor belting instead of conveyor chain for better robustness. In operation, the computer was constantly being reset. The trouble was, the belting sliding across plastic wear-strips made for a pretty good Van de Graaf generator. With the lights out, we managed to see an impressive spark jumping from cans on the conveyor to a proximity sensor. No quick isolation methods helped. In the end, we had to switch to conductive conveyor belts. Fun stuff. Visit Vegipete's *Mite Library for cool programs. |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

@vegipete I can imagine someone receiving a few free beers for making that discovery   |

||||

| Turbo46 Guru Joined: 24/12/2017 Location: AustraliaPosts: 1663 |

It depends. It's a matter of horses for courses. Maybe not for home or small factory installations. But consider a high voltage electricity substation and/or a lightening prone situation. Earth faults and lightening strikes can cause the local earth potential to rise by many thousands of volts. A lightening strike to that tree next to your backyard shed could briefly cause the ground potential of the shed to be thousands of volts higher than that of your house. In those cases, good galvanic isolation is essential. SCADA equipment for electricity substations should (and usually does) have galvanic isolation on all I/O. Bill Keep safe. Live long and prosper. |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8564 |

The systems I worked on didn't bother with opto-isolation or galvanic isolation on runs where lightning might be a problem. They don't give any protection at all at 36kV, never mind lightning so there's no point in bothering. :) (I used to love playing with the 36kV pressure tester at work!) It was multiple sets of fuses and transzorbs to a solid protective earth bar before you got out of the building. Same at the other end. Nothing protects against a direct strike on the cable. Not even the walls of the building sometimes. The main reason for isolation is to prevent accidental operation of something due to common supply wiring being not what it says. If you can guarantee a common return rail (which should only be grounded at one point if at all) then there's no real need for isolation. Station alarm batteries sometimes float both ends of the battery and use an earth fault detection relay to sense if either side gets earthed. You'll need isolation if you are working with both one of those and an earthed supply. Another reason is for intrinsically safe appications, where the maximum available power into the protected area is restricted to less than the point where it could cause an explosion or fire. That might mean using galvanic isolation, particularly for supplies which are typically limited to 2W maximum. Cows sometimes die in fields near electricity pylons. If the pylon gets a direct strike the immense ground current causes a huge voltage drop through the ground. The distance between a cow's legs is sufficient for a portion of that voltage to stop its heart. Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| Turbo46 Guru Joined: 24/12/2017 Location: AustraliaPosts: 1663 |

Our systems survived most lightning strikes and local earth faults at voltages up to 275KV. OK, maybe not all components, all of the time, but it's better to sacrifice a piece of peripheral equipment than the whole system. Obviously your mileage does vary. Horses for courses as I said. Bill Keep safe. Live long and prosper. |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8564 |

Very true. :) The trouble with lightning is that it's so unpredictable. You might have a system that's fine for many years but one rogue strike - and it doesn't need to be direct - will go through all your expensive protection. :( Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| Turbo46 Guru Joined: 24/12/2017 Location: AustraliaPosts: 1663 |

None of our I/O is connected directly to the main SCADA equipment. There is always an interface card in between. External high voltage surges never got through to the main system. Mind you, I retired over 15 years ago things may have changed but I believe the interface cards I designed are still being used. An interface card costs a couple of hundred dollars, a shelf or two of SADA equipment costs several thousands. 'An ounce of protection ...' Bill Keep safe. Live long and prosper. |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |