|

|

Forum Index : Microcontroller and PC projects : CNC Milling Front Fascia Panels for TFT displays

| Page 1 of 3 |

|||||

| Author | Message | ||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2979 |

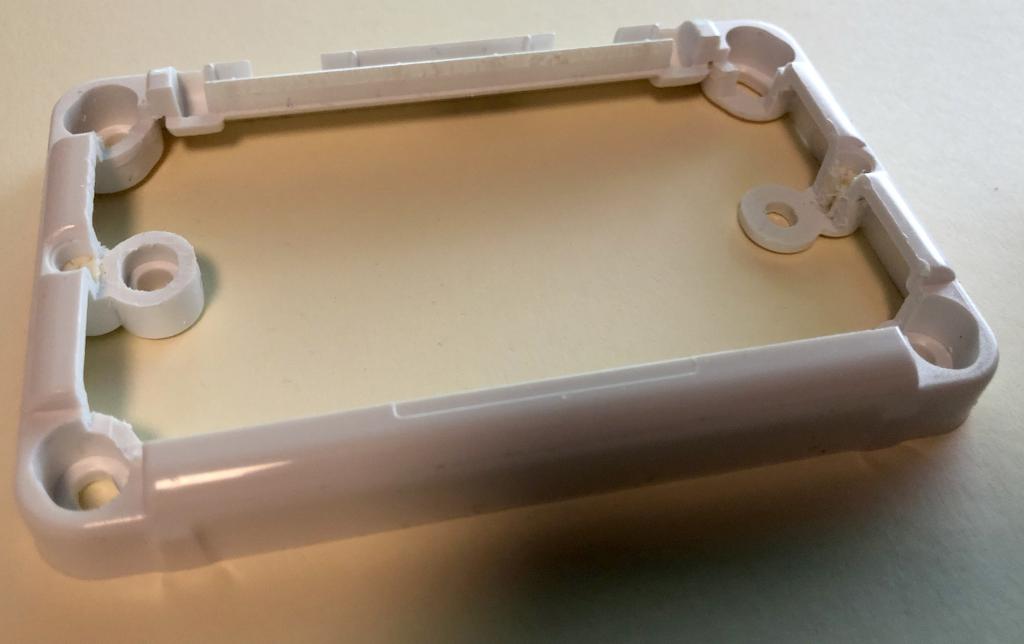

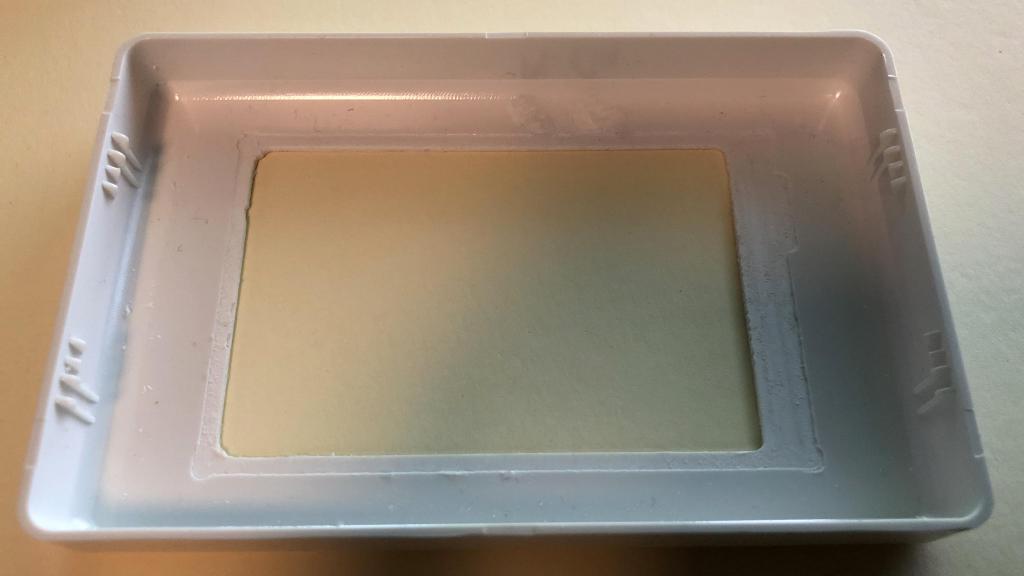

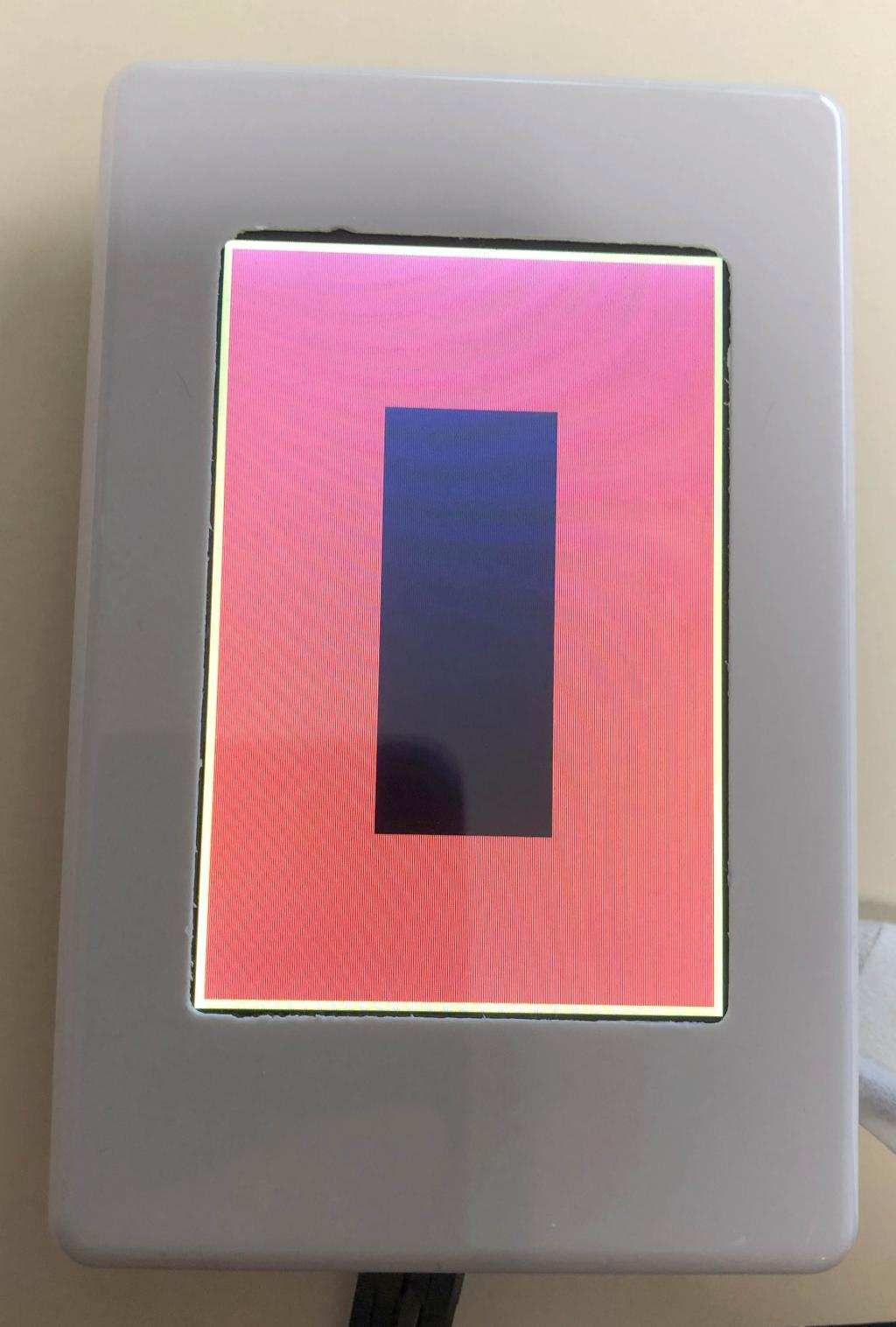

Hi All, I am new to hobby CNC cutting and I am sure I have done a lot wrong but I have been playing around with trying to cut fascia panels for a 3.5" TFT (specifically ILI9488) My results are reasonably good but as you can see they are still a bit rough. It is a work in progress. I started with blank Wall Plates (same size as a domestic - well in AUS- double power point) Here is a link to the local hardware store for the Wall Plate. >>> DETA X6 Blank Wall Plate <<< Here are my results to date. Rear Panel before and after cutting (take the screws out before milling just in case):  Here is a view showing cut outs on Rear Panel:  Here is the display fitted into the rear fascia, there is about 0.5mm movement so it sits very well and self locates (within the 0.5mm)  Here is a view of the inside cut for the front fascia: Note I also did a shallow cut around the viewing window and a small knock-out to allow the Touch cable to not get crushed, this allows the screen to `self centre' well that's the theory.  Here it is fully assembled: (I drew a yellow box with a red on inside it to show the limits of the display.)  I am getting a bit of 'chatter' with my CNC (an el-cheapo 3018) and the material is made of PolyCarbonate which is quite brittle hence you can see small chips around the viewing window. If Anyone is interested in trying their own here are the 2 .NC files Final MASTER Fascias 3-5 inch.zip FYI I used a 3mm 4 fluted spiral router bit and the origins are set so that the CENTRE of the cutter is directly over the intersection point of the 2 guide rails I fitted to my waste-board. (I previously cut 2 x 10mm wide channels and used some 10mm U-channel to act as guides). I push the fascia fully into the intersection point of the two guides and secure them. With the front Fascia I secured it with some double sided GEL tape (face down) and it seems to hold quite well. The Z origin is set so that the cutter just touches the centre point on the inside of the face. With the Rear Fascia I screwed it down in the four corners (face UP) and it seems to hold quite well. The Z origin is set so that the cutter just touches the centre point on the top of the face. NOTE! BEWARE! the RHS screws need to be small head I think mine are 5mm dia and the need to be screwed at the outermost extremity of the elongated holes so that the cutter will miss them, The LHS holes are fine as there is clearance of about 4-5mm) Re. The LHS screws, SMALL head and the top hole screwed as HIGH as possible and the Bottom hole screwed as LOW as Possible. It is the Y-direction of cut that could hit the screw heads. If there are any questions or suggestions I am open to both. I am going to try various settings to see if it can be improved and the wealth of expertise on TBS will be welcome to slap me over the head and tell me how I could have done better. Enjoy, Regards, Mick Edited 2022-07-07 16:42 by bigmik Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

| Andrew_G Guru Joined: 18/10/2016 Location: AustraliaPosts: 874 |

Congratulations Mick, I still haven't got my CNC working so I'll be looking to see what suggestions 'shedders' come up with. Cheers, Andrew |

||||

| matherp Guru Joined: 11/12/2012 Location: United KingdomPosts: 10965 |

Mick Suggest you try a single flute cutter. The key thing with plastics is clearing the swarf and a single flute is much better at this. Spindle speed should be as high as possible without causing any melting |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2979 |

Hi Peter, I did initially try a single flute cutter but because of the roughness and slight chipping I went and bought a 4 flute. The results were much of a muchness, Cutter speed is as high as I can get it running on the stock motor, I set to 10000 RPM but I don't think the motor actually runs at that speed, (Maybe its time to test it with a pic and phototransistor), I think the biggest issue is cutting Polycarbonate it is very brittle. I am thinking of cutting from the front instead of the back for the view window but I would have to use clamps and I am still nervous about them and it might flex the fascia. Anyway thanks for the advice I might try the straight flute again as I have changed my speeds and depth of cuts since I changed over to the 4 flute. Another Idea I have is to cut the view window 0.5mm smaller and have to finish off by hand. Keep the suggestions coming I have 4 more fascias to destroy. Regards, Mick Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

| matherp Guru Joined: 11/12/2012 Location: United KingdomPosts: 10965 |

I'm cutting at 24000RPM with small cutters (2mm). |

||||

| MikeO Senior Member Joined: 11/09/2011 Location: AustraliaPosts: 275 |

I cut some wall plates some time ago, I was using 2.8" lcds , see my posts here , I think I used similar wall plates, I can dig out the CNC details with cad files etc if interested. Mike Codenquilts |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2979 |

Hi Mike, Yours looks much nicer than mine, but I am still experimenting. Without updating my spindle motor I can’t do more to boost the spindle speed, that may be on the agenda soon. What machine are you using? As fun as my 3018 (standard) has been I can see the limitations in it. I might be better off putting money into a better, more sturdy model than trying to upgrade this model. Mike, how did you obtain the curved cut around the cut out viewing window? It looks top notch. Regards, Mick Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

| MikeO Senior Member Joined: 11/09/2011 Location: AustraliaPosts: 275 |

Hi Mick, the trick with plastics like acrylics, HDPE etc is if the cutter gets hot and melts the plastic back on to the work. So you need to use high feed speeds to the low rpm (relatively) and also small cutting depths. My mill is a bit bigger than yours and i have a 800w vfd which will do 24000 RPM but you should be ok with yours just have to experiment with feeds and speeds. .jpg) .jpg) I use 3mm single flute up cut end mill, Try Adams bits here I use CamBan for a Cad program, I have attached a Zip file with all the files for the project you won't be able to read the CamBan files but all the generated Gcode files are there which you can open in an on line viewer , this one is easy. Actually CamBan has a demo so you could look at the files. There was a lot of operations from memory to get the desired result but they worked out OK. Wall Plate LCD Housing.zip Cheers Mike Codenquilts |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1217 |

Mick, I had a look at your NC files, viewed them in candle, I cant see why the spindle has cut a little further into the corners of the face plate, unless there is some backlash T8 nuts, but that can be fixed a bit. For rounded corners it would need to be drawn in the original 2D drawing, Inkscape or what ever. The surface the end mill has cut, looks a little rough like it has grabbed due to heat, it might help having some compressed air cooling it while running, its what I will have to do with thick perspex cutting....have one of those air brush compressors might do the job. I'm no expert either.  Travel speed and cutting overlap also change the quality of the cut, sort of trial and error. Would be interested to see what the spindle speed really is. Mike has a nice setup there,  Cheers Aaron Off The Grid |

||||

Chopperp Guru Joined: 03/01/2018 Location: AustraliaPosts: 1116 |

FYI I just read an article from EW stating "Be careful with low-cost ‘500W spindles’ for CNCs" referring to the 3018 here It may be of help if considering upgrading. Brian ChopperP |

||||

| MikeO Senior Member Joined: 11/09/2011 Location: AustraliaPosts: 275 |

Hi Aaron those corners you are referring to are intentional i believe they are "overcuts' they are for where a recess for instance is to receive an item with square corners to ensure it will actually "fit" into the corner which would other wise be round , the shape of the tool. Mike Codenquilts |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8564 |

Just a quick question if I may? I know virtually nothing about this subject. :) Do people ever use some sort of cutting lubricant or coolant when working with plastics? I only ask because WD40 is commonly used when working with aluminium, where it makes processing quite a bit easier. Some grades of aluminium, although not as soft as plastics, share some cutting characteristics like a tendency to grab and tear under some circumstances. Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2979 |

Hi All, About to retire for the night, I will absorb all your suggestions tomorrow. But quickly, each corner of the shallow cut is so the sharp corners of the glass of a TFT will sit, otherwise the corners would be round and the TFT could not nestle into the the cutout. Also I don’t seem have issues with melting, in fact the cuts seem to peel off relatively cleanly, albeit the swarf is sometimes still attached to one side of each cut and needs to be trimmed off. No sign of melting. I ‘happen’ to have a few fascia’s from my many miscalculations so I have some to experiment with. I have generally been slowing the feed speeds down (Easel defaulted to 680 odd mm/s I have progressively reduced this to 200, maybe I should increase it?) I am only taking 0.3mm depth cuts (the fascia is 1.25mm thick at the front section I am cutting the window out of) I do take 1mm cuts into the less important rear panel as I end up taking 10mm deep in sections. The machine shakes and rattles like my old bones at times.. I am going to attempt to stiffen the gantry with braces and see what I can do with the Z axis as I reckon there is some slack there. I did read up and the stock motor is supposedly a 10000 RPM type. Anyway, it is all new and a heck of a lot of fun. I will check out in more detail tomorrow. Regards, Mick Edited 2022-07-07 23:21 by bigmik Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

| vegipete Guru Joined: 29/01/2013 Location: CanadaPosts: 1160 |

Be cautious using any cutting lubricants with some plastics, particularly polycarbonate. We performed tapping operations on polycarbonate under water. (UHMW, PVC, nylon, acetal are generally fine.) As Revlac posted, compressed air is definitely your friend, to evacuate chips and cool the cutting zone. Visit Vegipete's *Mite Library for cool programs. |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8564 |

Thanks. :) Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

palcal Guru Joined: 12/10/2011 Location: AustraliaPosts: 2039 |

I contacted JAYCAR and ALTRONICS here in OZ re getting some made, but they weren't interested. I'm amazed someone doesn't make them. "It is better to be ignorant and ask a stupid question than to be plain Stupid and not ask at all" |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2979 |

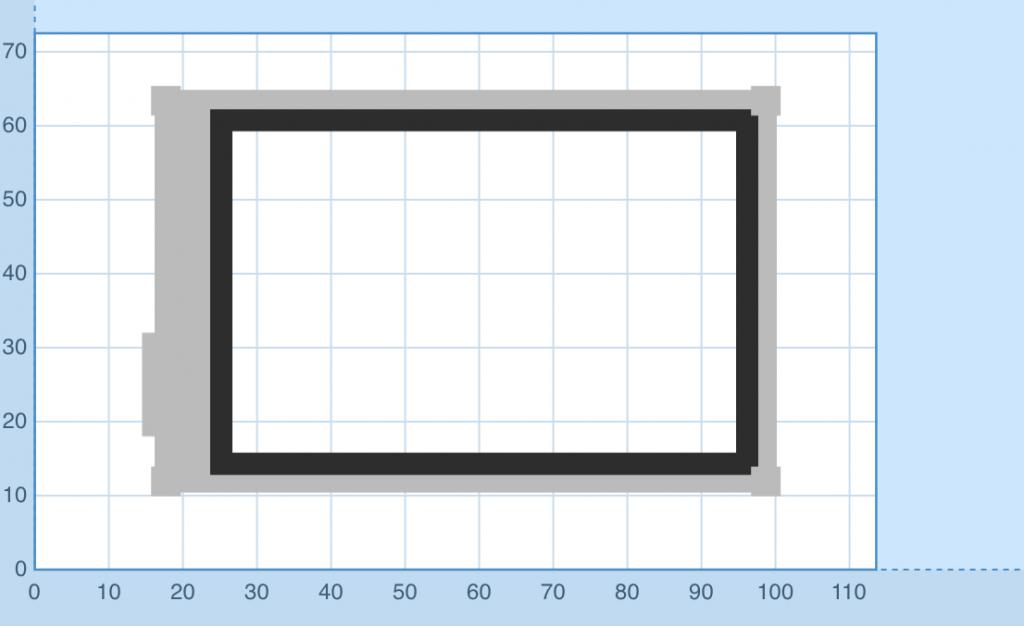

Hi All, I was initially embarrassed after MikeO posted his lovely fascia cuts. But now I am glad that I actually posted this thread, In all honesty the photos seem to highlight every issue in my panels, They dont look as bad in the flesh but there are still two nasty nicks in the cuts (one top and one bottom in my assy picture). Anyway, it is going to take some time to digest what this treasure trove has revealed to me. @MikeO, Wow your CNC is a real one, I started my working life as a fitter and Turner and worked on mills an lathes but they were more solid like yours (and larger) the 3018 is a pathetic toy in comparison but it is what I have and I am sure that I will get exactly what I want even if it means cutting the window smaller and hand finishing the last say 0.5mm of the cut. I had a quick look at CamBan and it looks nice but at $190 it is about what I paid for my machine, I would love to get a better CNC in the future and then I can consider a decent program like CamBan. Easel is OK but severely limited compared to their Pro version (something like $25US per month which is way over the top, I might not even use it for a couple of months and then do one small job. I have been working through its foibles as well, so far it is working OK for me. I download the G-Code and then use the bog-standard Grbl-control program that came with the 3018. Basic and I probably would like to find a better even if its a paid version GRBL control program. @Revlac, The cuts in the corners are by design, I made the recess 0.25mm deep and with 0.25mm play along each side so that the glass of the TFT would `self locate’ as the glass has sharp corners I needed to `knock out’ the rounded corners. Here is my Easel design, the grey rectangles are currently 0.2mm deep the black 1.3mm deep (ie cut through completely). You can clearly see the small squares I use to knock out the corners. There is another one to provide a bit of clearance for the touch ribbon cable.  @Brian, I saw there are motor upgrades, the 500w motors may be good but I think the 3018 is not rigid enough in the Z-axis to use to its fullest, I think that a better option is to put that money towards a better, more rigid unit. There are drop in motor replacements for the 3018 that offer 20000 RPM that I might consider (only about $60) in the future but I watched some you-tube clips and it sounds like a jumbo jet engine. I will need a sound proof box (which is on the agenda) first. @Mick (The other Mick) I am interested in that too, do lubricants help or hinder when working with plastics? In my trade life I never cut plastics (well maybe Teflon or Nylon blocks a couple of times I dont remember cutting fluid those times) it was almost always metals of some sort or the other. @Vegepete, Can you elaborate a little bit on being cautious Re. Cutting fluids please? I have a blower that I regularly blow away the swarf as I am cutting, It is not on all of the time but I use it when I think the collection of swarf is too much and may impact on the cutting. @Palcal, That is interesting as AndrewG sent me a link to a Jaycar product that had a fascia similar to the one MikeO made for a smaller TFT but the price was about $140AU (crikey I would want it made from GOLD for that price) but I couldnt find it on their site, I will look for it and if I can find it I will post here. Thank you all for your suggestions and most helpful advice, my next steps to try are (not necessarily in this order) Stiffening the Vertical gantry with some solid braces. Trying to cut the front fascia from the front (as opposed to the rear). Trying a straight flute cutter with faster X-Y and smaller depths Trying a Vee Groove cutter. Reading my prayer book (aka TBS) Having a beer (most likely a stout) And most of all Having some fun. At $4.35AU each these panels would make a fantastic wall mount for domestic use but they MUST look the part before my wife would allow me to mount one on our wall. Take care all and I look forward to any more comments you may have. Kind Regards, Mick Edited 2022-07-08 11:25 by bigmik Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

| Andrew_G Guru Joined: 18/10/2016 Location: AustraliaPosts: 874 |

Hi Mick (BigMik that is), A couple of small corrections if I may be so bold. It was an Altronics product and it is now ONLY $99. It is for a 2.8" display and I'm not sure if that includes the display - it might? I was after a 3.5" display and have no use for an Arduino that might come with it. (But is does look neat) To MikeO, I'm very envious of your CNC - I only have a 3018 toy the same as Mick's. If anyone found a reasonably priced option for a 3.5" display I could be interested . . . Cheers, Andrew |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

A gazillion displays on the market but very few off-the-shelf, professional quality bezels/enclosures. Craig |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

Double post Edited 2022-07-08 13:57 by Tinine |

||||

| Page 1 of 3 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |