|

|

Forum Index : Microcontroller and PC projects : G-Code interpreter in BASIC anyone?

| Author | Message | ||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

Shouldn't take much to do this but just wondering if proven code already exists. Looking at making my motion controller compatible with GrblGru MMBasic should be perfect for this  Craig |

||||

| Martin H. Guru Joined: 04/06/2022 Location: GermanyPosts: 1357 |

You wish, the Pico to controll the Steppermotors of your CNC? Something like "Marlin"? But I dont know if there is a Marlin Version on the Pico. Couse most 3D Printers / CNC use Arduino Board to do the Job. 'no comment |

||||

| circuit Senior Member Joined: 10/01/2016 Location: United KingdomPosts: 295 |

Gosh, you have really got my interest. I am just starting out with the idea of building a CNC router and this sounds like a possible way to go. |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

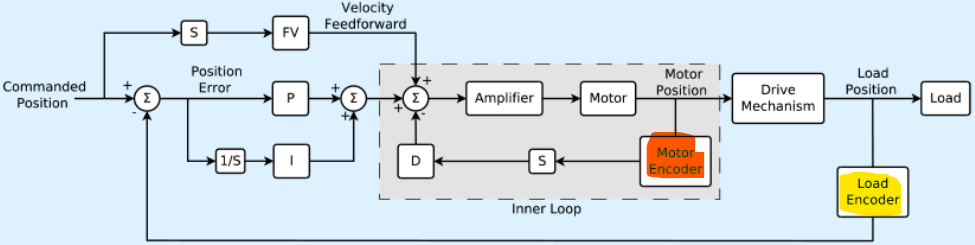

No, the PicoMite is the front-end to my Parallax P2-based motion controller. The objective is to provide a proper closed-loop-servo alternative to all of these stepper systems   CNC = Computer Numerically Controlled I regard open-loop steppers: Computer Numerically Commanded No feedback = no "control". In fact, my method is to utilize "dual-loop-feedback". The device highlighted in red is what is typical and provides loop stability but the controller is never aware of mechanical backlash. Maintenance personnel can't understand why parts are varying when the controller always reports "axis is within tolerance"  I prefer to use both the red and yellow highlighted devices to provide stability and backlash immunity (within reason).  Craig |

||||

| matherp Guru Joined: 11/12/2012 Location: United KingdomPosts: 10965 |

Have you looked at closed loop steppers? - cheaper than servo technology but with the same guaranteed accuracy with the right driver |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

Yeah, still too limited. Torque drops-off at a half-decent speed and they can't get close to the 3,000 - 6,000 RPM that I use. The biggie for me though is that they can't be torque limited and this is the problem I have with Annin Robotics. He's doing an amazing job and finally switched to closed loop but closed-loop steppers. Today, robots are becoming "cobots" (collaborative robots). They can work alongside humans without a protective cage because they are able to torque-limit. A setup person used to have to use a teach pendant whereas now they can simply grab ahold of the end effector and drag it around and have the cobot learn the path. This is all achieved by limiting the output of the PID filter. I have used this method for decades for setting-up my machines. If it crashes, all we get is a harmless "thud". Examples at 1:43 and 4:13 Craig |

||||

| led-bloon Senior Member Joined: 21/12/2014 Location: AustraliaPosts: 208 |

I doubt this will be any good for you, can't find any of my doco/drawings with it, and (unusually) very few comments in the code. Good for a laugh or how not to code it, maybe? led mite-cnc.zip Miss you George |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

any of my doco/drawings with it, and (unusually) very few comments in the code. Good for a laugh or how not to code it, maybe? led mite-cnc.zip There we go    Many thanks  Craig |

||||

| Volhout Guru Joined: 05/03/2018 Location: NetherlandsPosts: 5703 |

Today, robots are becoming "cobots" (collaborative robots). They can work alongside humans without a protective cage because they are able to torque-limit. A setup person used to have to use a teach pendant whereas now they can simply grab ahold of the end effector and drag it around and have the cobot learn the path. Craig I have a colleague workin on one. They run on several NVidia Jetson modules, accompanied by a RPi4 for motor control. The NVidias are used for AI and protecting the humans. PicomiteVGA PETSCII ROBOTS |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

I have a colleague workin on one. They run on several NVidia Jetson modules, accompanied by a RPi4 for motor control. The NVidias are used for AI and protecting the humans. Cool. Is this a new development? |

||||

| Volhout Guru Joined: 05/03/2018 Location: NetherlandsPosts: 5703 |

watch this: video PicomiteVGA PETSCII ROBOTS |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

video But running on an RPi4? Must be bare metal if it is  They still have latency/jitter issues when running 3-axis LinuxCNC. They still have latency/jitter issues when running 3-axis LinuxCNC.Craig |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

Linux CNC RS274.pdf  Craig |

||||

| Tinine Guru Joined: 30/03/2016 Location: United KingdomPosts: 1646 |

Have been in touch with the creator of GrblGru. I really hope he's up for it. I have a mill here that needs a new CNC and I'm totally underwhelmed with every existing option out there. All half-baked IMO  Craig |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |