|

|

Forum Index : Wanted : Wanted: Source for 8-10Kw toroid cores.

| Page 1 of 2 |

|||||

| Author | Message | ||||

| sPuDd Senior Member Joined: 10/07/2007 Location: AustraliaPosts: 251 |

Hello all, I'm building an 8-10Kw 48V inverter. The inverter etc I can make, but I've been unable to find a suitable source of cores. The Asian manufacturers will ship them if you want a minimum of 10 units. Is there an Australian manufacturer who has cores I could stack for more power, or just has that kind of item without making a one-off? Is there a large toroid used in some piece of equipment that I could strip down & stack for a new core? I'd like a larger inner diameter to accommodate easier winding. I may wrap the primary as multiple large enamelled winding wire inside fibreglass woven cloth tubing rather than PVC insulated regular cable. Better cooling. The whole core will be carefully supported and forced air cooled. My minimum load power is about 300 watts. Average load is about 1000 watts. High load is 7500 watts for a few hours. There will be an EV slurping up more power at a later date. Also, this will not be a budget build, so spending money on a quality core that lasts forever is where I stand. Much appreciated, sPuDd.. Edited 2023-03-30 16:03 by sPuDd It should work ...in theory |

||||

| Godoh Guru Joined: 26/09/2020 Location: AustraliaPosts: 531 |

You could try someone who makes Torroids and sells inverters, transformers etc. Tortech are one mob I know of, I have seen another company in WA advertising on Gumtree but can't recall their name at the moment. Pete |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1153 |

sPuDd. You could try, https://www.aemcores.com.au/technology/unicore/duocore/ Mark is very helpful if he is still there. Cheers Aaron Off The Grid |

||||

| sPuDd Senior Member Joined: 10/07/2007 Location: AustraliaPosts: 251 |

Thanks Godoh and Revlac, I'll give them both a call and see if they have any cores available. sPuDd.. It should work ...in theory |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

I priced getting Toroids made some time ago and the prices were huge for an Australian made one. Getting them from Asia is much cheaper but the freight is a killer. If I were you I would go around to all the local solar installers and offer beer for Aerosharps if they find any. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 906 |

I scored an early type BP 6Kw GTI with a toroid. It is a rebadged SMA and the toroid is encapsulated, but that would still make a great start. I also priced a toroid from AEM Cores and while I ended up building up a core using most of 4 x 3Kw Aerosharp toroids, I think if I was starting again I would simply pay the money. I'm in SA, so could avoid freight costs by picking it up. The reason I didn't buy one was mainly because to get the size I wanted I still would have had to sandwich two together, though I'm pretty sure I could have still made it work with a flatter and larger diameter. An advantage would be that they also 'anneal' them or whatever the process is once wound. IRRC 100mm is the widest material they use, so there are limits still. Having said that, it wasn't really all that difficult to build up the cores I used ... BUT ... one version of 3Kw Aerosharp toroids is made up of hundreds of short pieces of material ... and that would be difficult to use to keep nice and tight. On the other hand, the other version with blue tape around it, are wound with one continuous piece and they worked beautifully. I rang around several years ago and found a repairer who was happy to sell me any inverter he got in, for $25 each. I don't get to Adelaide all that often, but when I do I call in and pick up various stuff. Apart from all the Aerosharps I've collected, I occasionally pick up something else just to take home to play with. Best entertainment you can get for $25.  I had never seen any SMA stuff, so bought one to check it out. While it is transformerless (that's where the TL comes from in the model number) I was super impressed at how they are built. With a power driver, you can have it apart and down to all its basic bits inside minutes ... like 3 or 4 perhaps. Not that anyone ever fixes them I suppose, but all the same I was impressed with the design and the build quality. Cheers, Roger |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1210 |

Hi sPuDd, sorry to bump an old thread, what did you do about your Toroid core search ? I am also in the process of creating and building up a 7kW continuous inverter that should easily handle peaks up to around 15 or 20kW. If you haven't solved this yet below is my proposed solution. I am not keen to wind up a toroid from scratch and have been considering what approach to use for a while now. Before I went on holiday some months back I had recently bought 2 x complete 3.5kW Aerosharps ($50 each). They have a big Toroid, 195T 230V winding and a 212T 250V secondary. I propose to unwind 17T from the outer 212 turn secondary (making 195T) and place the 2 x 195T in parallel for lowest impedance. If I do this to both toroidal transformers and then place one on top of the other and wind just a 13T primary that passes through & around both cores and parallel the 4 x 230V windings the result should be quite good, The primary is just 25mm square (or 32mm) PVC single core cable. I initially experimented with a 25T primary on 1 toroid, which gave the best results, but 2 stacked toroids means the primary turns are halved. That is the basis for my solution, using 2 x professionally wound toroids (albeit with 17T removed from the outer windings), sure it doesnt give a big hole in the centre but it appears the 13T primary should be a cinch to add to the ~ 52mm central hole. Stacking 3 such cores and using an 8T primary is also possible but would be hard to physically manage, the idling power for the 2 cores would be ~ 38W, 3 would be ~ 57W If instead of removing 17T from the 250V winding you added 17T to each 230V winding and paralleled up all the 250V windings but ran the output voltage at 230V from the 250V windings, driven from a 9T primary, idling is a bit better at ~ 16.5W for each toroid or 49W for the 3 toroids. If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1210 |

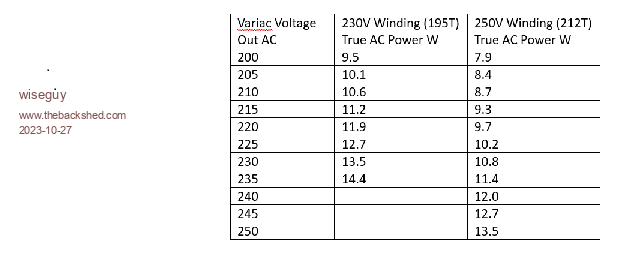

Hmm those figures of idling current seemed a bit high so I went and remeasured with a Variac and an accurate watt meter. Sure enough they were very wrong. The figures I posted above were logged about a week before posting and were for the total DC Power idling Watts for various output voltages using an EG8010 controller drive, no wonder they were a tad high! I relogged both windings separately against various 5V increments from 200V to 250V and made a table of the results for the Aerosharp 3.5KW Toroid.  So reposting the last paragraph from the previous post of the idling watts with the CORRECT values: Stacking 3 such cores and using an 8T primary is also possible but would be hard to physically manage, the idling power for the 2 cores would be ~ 27W, 3 would be ~ 40.5W If instead of removing 17T from the 250V winding you added 17T to each 230V winding and paralleled up all the 250V windings but ran the output voltage at 230V from the 250V windings for a 3 stack, driven from a 9T primary, idling is a bit better at ~ 10.8W for each toroid or 32.4W for the 3 toroids. Note this is AC power required for just idling an inverter with no load and does not take into account inverter and solenoid etc running currents. Edited 2023-10-27 11:33 by wiseguy If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 906 |

Hi Mike, welcome back. I assume you're back from your extended holiday. I know my theory is not too good but I didn't realise that stacking two toroids means you halve the primary turns, especially if the secondaries are all paralleled. I still think you should bite the bullet and wind one from scratch.  We've all seen your projects and I'm sure it would be a piece of cake for you. If I ever get mine finished ... and if I ever decided to build another one ... I'd just buy a core from AEM and wind it with new wire. It's gunna cost heaps regardless ... either in $ or in time. We've all seen your projects and I'm sure it would be a piece of cake for you. If I ever get mine finished ... and if I ever decided to build another one ... I'd just buy a core from AEM and wind it with new wire. It's gunna cost heaps regardless ... either in $ or in time.Cheers, Roger |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1210 |

Hi Roger, yes back now and nearly finished my current to do jobs list - that was not created by me..... So time to dust the cobwebs off a few projects and the soldering iron and have some more fun. With regard to the transformer primary turns, lets look at scenario 1, forgetting secondaries and just looking at the magnetising winding force. We apply excitation and have magnetising of the one toroid of 1 tesla. Now lets stack 2 transformers with the same number of primary turns and I am sure you will agree that the two Toroids now share the megnetising force equally and we end up with 0.5 Tesla each. If we now halve the primary turns they will now be back to 1 tesla each. We doubled the iron mass cross section so we need to double the ampere turns, which from a given excitation means we must halve the turns. So if 1 tesla on 1 toroid originally gave me 230V then both of the stacked transformers with wound 230V secondaries will each be back to 230V and can be put in parallel. I will wind my own Toroid - but with a caveat, only if I cant achieve what I want from existing pre-wound transformers and then applying some lateral thinking to hopefully find a solution that allows me to avoid a rewind! So hope you're having fun & have kept up your Altium skills. If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 906 |

Thanks for the transformer theory lesson Mike, I'm going to have to study some more. Regarding the toroid, I do have to admit that if you can make it work, it would save a lot of time and effort. Keepis used stacked toroids for his system didn't he? ... and it appeared very successful I thought. And I reckon in the very early days Oztules did too. Anyway if you end up having to wind one, I'm happy to help out if you'd like. I'm afraid I haven't done any more with Altium, though I was really pleased with how my boards turned out ... so thank you again for all your tutoring. I have been slowly making progress with my system and can see an end to it eventually ... just so much work with everything included. I've put up all the rails for 48 panels and fitted half so far and wired them up ... fitted the fuse boxes ... nearly finished welding up my frames for the Warpverter and all the MPPT's. I'll get there.  Cheers, Roger |

||||

| lostmark Newbie Joined: 25/02/2023 Location: AustraliaPosts: 1 |

Hi Mike, I'm starting to think about transformers for a new design. (I'm wondering about GaNFETs and 500kHz. There'll be some learning to be done!). I like your idea of stacking cores, modifying and paralleling original pri & sec, and adding new primary. If you keep can keep your new primary copper loss lowish, you could expect a healthy increase in continuous power rating of each core, given you've halved the new secondary resistance. You'll lose some surface area for heat dissipation, and have losses in the new primary, so a doubling of continuous power would be too much to expect. But it should be a healthy increase nevertheless. But I'm yet to understand what type of wire you'd use for such high current windings. And I presume these ex-GTI transformers are rated in still air? So the addition of a (switched) fan could allow quite a bit higher continuous load. Cheers, Mark |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 906 |

Hi Mark, welcome. Maybe it might get you more views and discussion if you start a thread over in the electronics section. This part of the forum is rarely visited for some reason, so it would be a pity to miss out on some answers simply from a lack of awareness. I can certainly offer some views on winding toroids ... it is no where near as onerous as some seem to believe.  Cheers, Roger |

||||

| Godoh Guru Joined: 26/09/2020 Location: AustraliaPosts: 531 |

Hi Roger, I am soon to begin a wind on a torroid for my inverter. I am wondering what method you use to wind your transformers. I have seen methods where one uses a hoop of plastic pipe with the wire inside it. And the old shuttle method. What one do you use? I have a stacked core that is 190 X 90 X 100 h. So it will be reasonably heavy when finished. Pete |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 906 |

Hi Pete, I only use a shuttle when I unwind old toroids and can definitely recommend using a plastic hoop for winding. I did a post somewhere with more details of the process ... I'll see if I can find that. Weight is not really an issue when winding because the core sits in one spot for quite a while ... then you jiggle it around a few degrees to get to the next section. Well that was my experience anyway. My big tx was certainly heavy when I finished and difficult to move around ... but I didn't find it an issue to wind. It's about 57 or 58kg now!!!  Hopefully Mark will start a new thread so others will see it and chime in. Cheers, Roger |

||||

| Godoh Guru Joined: 26/09/2020 Location: AustraliaPosts: 531 |

Thanks Roger. I will have to have a look at how the plastic hoops are set up. Sounds like the way to go. I will be winding my transformer with 2 in hand secondary, possibly 2 x 2.5mm wires. Depends on what wire I can source in Launceston. Cheers Pete |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 906 |

Hi Pete, I found the explanation I did before ... here There are pictures in several places thoughout that thread as well. I have some video I recorded at times but would need to find it, then edit it. Until you start doing it, it sounds difficult ... but if I showed anyone ... a few minutes later they'd be saying get out of the way and give me a shot.  Cheers, Roger |

||||

| Godoh Guru Joined: 26/09/2020 Location: AustraliaPosts: 531 |

Thanks Roger, I will study your diagrams, and make a hoop. Cheers Pete |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 671 |

A tip for you Pete, it will cost you nothing but could be appreciated further down the track  I know you have a 24V system (you might regret when you see what long time currents a 3.6KW car charging load drag from your battery  ) but my suggestion is: wind the Primary of your toroidal transformer *also* as two parallel windings. ) but my suggestion is: wind the Primary of your toroidal transformer *also* as two parallel windings.That way you could later easiy connect them in series for a 48V primary. Have fun with the winding, it only looks confusing the first time and is a piece of cake after the 6th toroid    like I know by now. like I know by now.Just think it through first, ideally the layers of parallel windings should go completely around the core to evenly distribute the field. You might consider to keep the primary/secondary start/ finish a bit apart so its easier to connect later when its finished. Do measure the magnetising current after you wound the secondary (it might need a startup load if you do not have a variac). When the primary is on measure that current again, it should be identical to confirm there is no short. Tell us your initial magnetising current and the core size so we know you are in the right ball park. |

||||

| Godoh Guru Joined: 26/09/2020 Location: AustraliaPosts: 531 |

Hi Murphy, thanks for the tips. I bought some 2.8mm wire for the secondary and am nearly half way through getting the turns on. I am thinking of using flat rectangular wire for primary, and what I saw at the shop would suit the parallel arrangement fine. It would also make it easier to connect tails to connect to the power board. My core is 180mm OD 90mm Id and 100 mm high. I will check the current when I get it wound. The place I bought the wire from said that they can dip the transformer in their varnish tank and bake it for me when I have finished. I will do that. Thanks Pete |

||||

| Page 1 of 2 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2025 |