|

|

Forum Index : Microcontroller and PC projects : Poor mans desktop mill 30x30x30cm for 150€

| Author | Message | ||||

| dddns Guru Joined: 20/09/2024 Location: GermanyPosts: 480 |

The paint of an Edding permanet marker is at least acid resistant. 45 years ago I drawed the traces by hand.. It smells good when wet, maybe it burns as well :)) And there are the oldschool photo inc coated ones. You could try to evaporate this instead of developing it :) Edited 2025-03-03 23:25 by dddns |

||||

| stanleyella Guru Joined: 25/06/2022 Location: United KingdomPosts: 2527 |

what you think? https://www.aliexpress.com/item/1005003294861607.html |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 7832 |

Looks as if it's not very rigid to me. Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| dddns Guru Joined: 20/09/2024 Location: GermanyPosts: 480 |

that the axes are driven via a trapezoidal spindle, which is not backlash-free. Expect no aluminum. The pictures look very nice as the ones of the A8net which is a construction for the bin. The Proxxon I used has reached its limit and I will have to replace it as the barrings and the motor brushes are dead..can you exchange this special spindle? But on the other hand side it is cheap. And if I am wrong and the precision is good enough..why not give it a try. Another plus is, that the travel paths of the axes are really large! |

||||

| dddns Guru Joined: 20/09/2024 Location: GermanyPosts: 480 |

Spindles are the best for a mill. But you cannot have as much pace for the fast moves than with a belt, simply because of the pitch. But you need a recirculating ball screw spindle like these |

||||

| stanleyella Guru Joined: 25/06/2022 Location: United KingdomPosts: 2527 |

Whereas a cheap 3d printer might work as an intro and you can modify it with your own printed parts, I reckon a router needs to be NOT cheap as it needs precision, so rigidity. The one I posted was extruded alloy. As said I got two 3d printers and one's just sitting there. I'll strip the extruder so just the carriage and sort a router head. it may work?? |

||||

| dddns Guru Joined: 20/09/2024 Location: GermanyPosts: 480 |

I really do not understand the market and the manufacturers. If the construction would be made of aluminum and recirculating ball screw spindles it would cost let us say 300 bucks more..so what? There would be still thousand of buyers in the world. |

||||

| stanleyella Guru Joined: 25/06/2022 Location: United KingdomPosts: 2527 |

wow, cnc spindle motors aren't cheap! I looked at my lidl dremel and it got a flexi drive which might be a lighter option. Edited 2025-03-04 05:09 by stanleyella |

||||

| dddns Guru Joined: 20/09/2024 Location: GermanyPosts: 480 |

yes why not, if the body of your printer is stiff enough. I looked for so long but from the ratio price/preciseness I think, that Proxxon is the best low cost choice. It is a 12V model with 20.000rpm and is absolutely play-free and is the cheapest. This is sufficient. |

||||

| stanleyella Guru Joined: 25/06/2022 Location: United KingdomPosts: 2527 |

thanks for the advice, as said I think it hanging as it's meant to with flexi drive might work, it would need a smaller mount, pipe clamp maybe. see what happens and software to use as it's not a 3d printer adding layers it's going the other way. let you know progress |

||||

| stanleyella Guru Joined: 25/06/2022 Location: United KingdomPosts: 2527 |

got to make a bracket for the "dremel" extension drive. stripped the extruder and heat bed stuff. |

||||

| Plasmamac Guru Joined: 31/01/2019 Location: GermanyPosts: 573 |

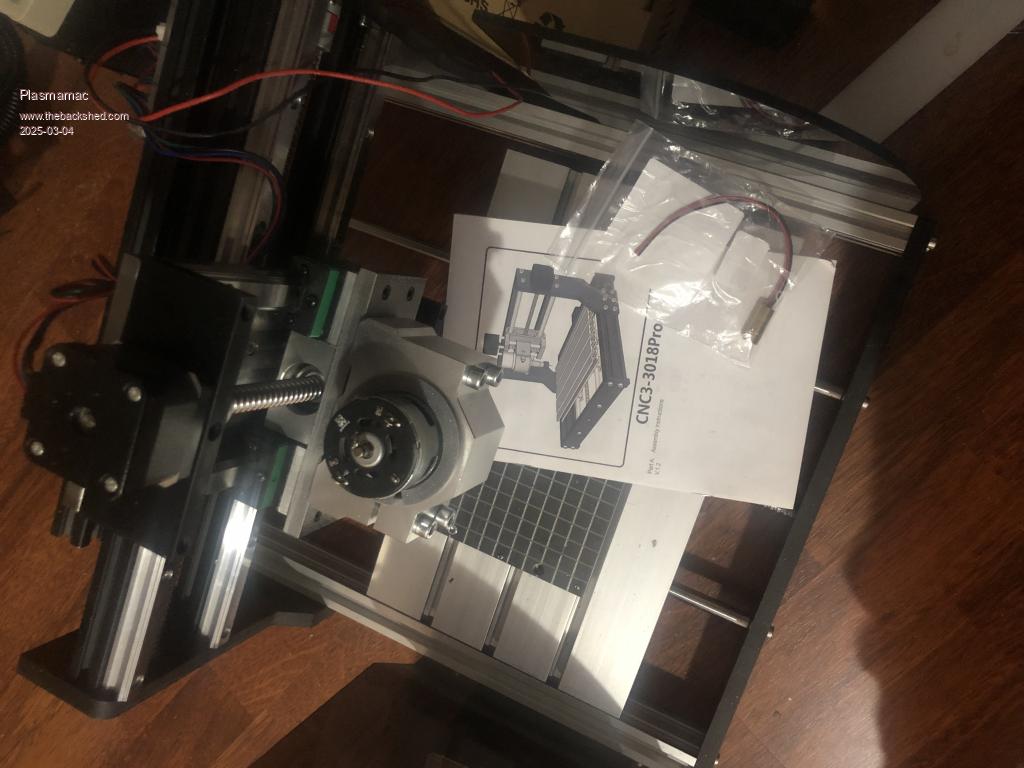

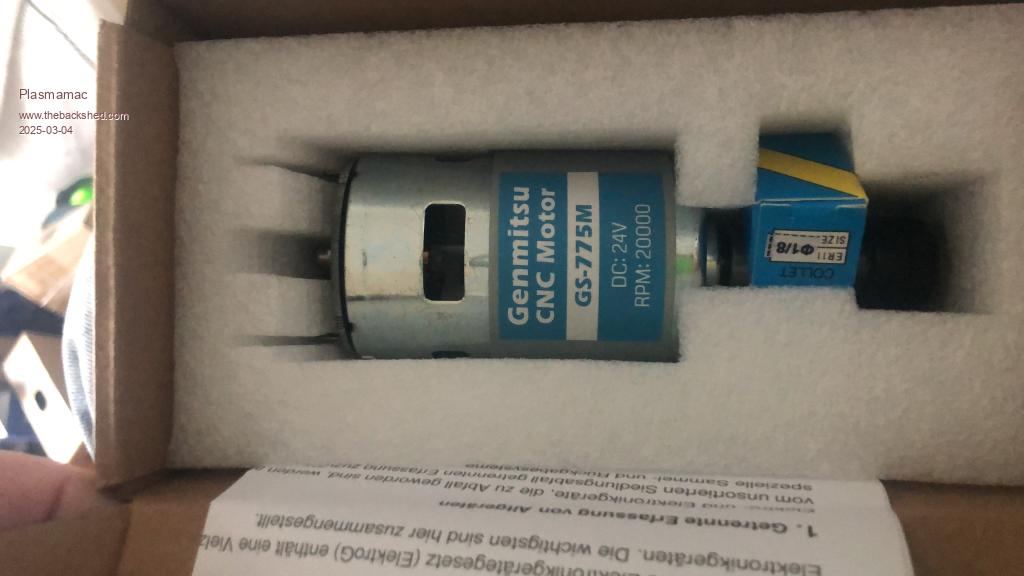

Got a cheap 3018 pro from a big seller for 100 bucks , build some stiffer axis because the original are death after A friend helps with some Alu parts and ready. A little motor is my Spindel and works like a charm.  Plasma |

||||

| Plasmamac Guru Joined: 31/01/2019 Location: GermanyPosts: 573 |

Hope it helpd Plasma |

||||

| Volhout Guru Joined: 05/03/2018 Location: NetherlandsPosts: 5036 |

Nice.... A wooden Gameboy... Volhout PicomiteVGA PETSCII ROBOTS |

||||

| dddns Guru Joined: 20/09/2024 Location: GermanyPosts: 480 |

Your result looks very nice! And it is always good to have friends as the modifications are well done. But in the end, it is always the same conclusion, that you have to modify and rework or it is not really usable. Are the axes driven by trapezoidal spindles? Did you try to mill a PCB as it is harder than wood? |

||||

| dddns Guru Joined: 20/09/2024 Location: GermanyPosts: 480 |

I doubt that you will get satisfying results. The A8 looks like I know it and this construction is definitely not stiff enough. The extension drive will be dead after 3 hour nonstop rotating (I guess). |

||||

| dddns Guru Joined: 20/09/2024 Location: GermanyPosts: 480 |

This is what I would use as a base if I had the oppotunity. |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 7832 |

Those flexi drives aren't up to it. They are too stiff and you would need to sort out some sort of lubrication or it will jam repeatedly. They are fine for their intended use, but not for running for a long time. There are many pretty high power motors on AliExpress, some with chucks. Is 12V 960RPM ok? There is a package with motor, bracket, speed controller & mains PSU for £22 +vat Still need a chuck though. That's a geared one. There are basic motors but the spindle speed can be pretty fast! inclusive kit 775 with chuck & bracket Edited 2025-03-04 20:54 by Mixtel90 Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| stanleyella Guru Joined: 25/06/2022 Location: United KingdomPosts: 2527 |

just ordered one Mick. thanks for the link. do I run it at 12V or put a voltage controller to lower voltage and revs? it may be a waste of time on this anet which is carp by anet standards. my other acrylic anet is a bit better built and manual bed levelling works... you get what you pay for I suppose. |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 7832 |

Speed will have to depend on what you are doing. Little drills are usually fast, but in acrylic you will need to run slower to prevent melting. I don't know about milling. Speeds will probably be lower than drills as the cutter diameter is greater. Also, it will depend on the depth of the cut and in what material. Although reducing voltage to a DC motor will slow it down, it also reduces the torque. A drill speed controller will usually be PWM as that keeps the voltage and hence the torque constant while changing the speed. You will need a decent amount of current from the power supply. Those motors can need quite a bit if they are loaded. Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2025 |