|

|

Forum Index : Windmills : My Smartdrive 2 stage Savonius.

| Page 1 of 2 |

|||||

| Author | Message | ||||

| retepsnikrep Senior Member Joined: 31/12/2007 Location: United KingdomPosts: 131 |

I have recently joined this excellent group and have been assembling a basic guyed Oil drum 2 stage Savonius VAWT using a LG Smartdrive generator.

I'm now at the testing and tweaking stage with the whole assembly rigged up in my workshop and me or wife spinning it by hand ;) At this time we are at the amazing and satisfying lighting a bulb when spun phase

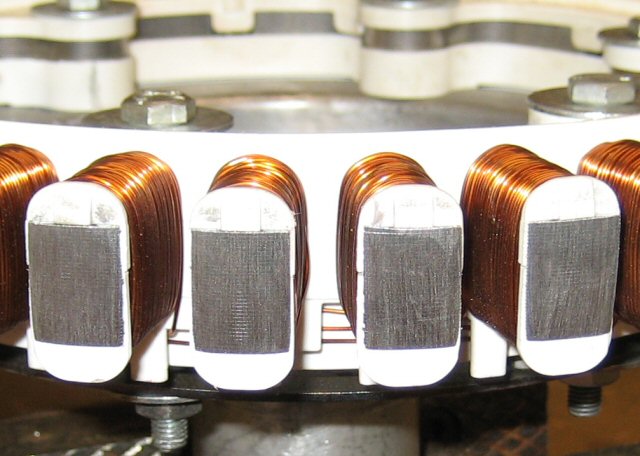

I'm using two standard 50 gallon drums with a central shaft. I'm using an ex LG washing machine smartdrive motor in standard 3 phase star config to try and get some output at low rpm. I have not done any de-cogging as yet. I using a standard 3 phase bridge rectifier made out of normal diodes at present, I have some Schottky ones on order. I am on the look out for unpolarised 100v 100uf caps to try that mod as well, once I have it up and running I may rewire stator depending on results. I haven't decided on a final system voltage yet, I'll wait until I get some power results and then decide as I have a fairly flexible battery system in mind. Sadly I live in a very sheltered and turbulent wind area, I already have a normal Air-X type turbine which really struggles to stay into the wind. Here are a few pics, I'll post more when it's up. Savonius 1 Savonius 2 Savonius 3 Savonius 4 Savonius 5 Regards Peter UK Gen1 Honda Insights. |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5019 |

Thats a nice looking machine Peter. I bet you are eager to get it out side into the wind. Would be very interested to see how it runs. The LG is very similar to the F&P motor, so I think the cap mod should work just as well. I dont think you will need to decog the stator. I built a Lenz2 vertical windmill, about half the size of your savonius, and it started a stock standard F&P stator easily, no need to decog it. But I did find the vibration from the F&P was amplified by the Lenz2 wings, making a drone noise, so I tried a decoged stator and it reduced the noise a lot. So I would try the standard stator first, see if its noisy before you consider de-coging. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| RonS Newbie Joined: 19/06/2007 Location: AustraliaPosts: 18 |

Hi retepsnikrep I did a lot of research with Savonius rotors some years ago. I used a single 44 gallon drum driving a vehicle alternator through a series of V-belts, the whole bolted onto the back of my ute (utility truck/'pickup'). I found the ideal overlap to be 29% of the diameter of the drum, plus allowance for obstructions (like your pipe-shaft, for instance). Direct drive is the only way to go with a Savonius. My system above generated just sufficient power at 40KPH to turn slowly, all the power being absorbed into the necessary 'gearing-up'v-belts and pulleys. A waste of time!.....but as a driver of cam-operated reciprocating pumps for water it was a success and many were sold in rural areas of Australia for that purpose. As you will learn from this forum, there are better ways to go, however, than a Savonius. For serious power, try a Miller rotor. Avoid strong drink. It makes you shoot at tax collectors ...and miss. |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

Nice job there Peter.

You've fitted that LG very snugly. It looks great. A little more height will be desirable once outside, though supporting such beasts at height is more difficult. Now for the important question... What colour is the wife going to paint it?  was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| retepsnikrep Senior Member Joined: 31/12/2007 Location: United KingdomPosts: 131 |

I have painted it same colour as floor as I had 20L of that paint in stock. Hard wearing and waterproof so should help protect it.  Gen1 Honda Insights. |

||||

| martinjsto Senior Member Joined: 09/10/2007 Location: AustraliaPosts: 149 |

very nice work peter, i have seen a few similar units in padocks around SW of Western Australia, and they seem to spin realy fast. seen others on internet, they sugest the 3 tier seems the way to go for the torque required when loaded although i havnot built one yet so i cannot comment directly. you would want to secure the unit well, especialy if raised off ground at a height. the central pipe is good, nice and strong, others i have seen are made around old bike wheels, seem to be a bit weak to me. do the LG's have the same amount of poles as the F&P? and can you get a different rotor like the F&P's for 7 phase. if not the 3 phase mods work well as gizmo pointed out. i have access to a lot of old machines from a repair shop, but i have not looked at the LG's, they look very similar might have to get one and do some experiments. well done again good luck and welcome to the group martin free power for all McAlinden WA |

||||

| retepsnikrep Senior Member Joined: 31/12/2007 Location: United KingdomPosts: 131 |

I have now decogged my LG UK Directdrive 36 pole stator prior to erection of my Savonius unit. Before decogging stator had very sharp edges to protruding coil lamminations, now rounded off quite nicely with a powerfile bought specially for the job ;)  Gen1 Honda Insights. |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

A bit late to be checking this now I suppose, but with 36 poles did you check to see if the rotor magnets are rectangular or arrowhead? There seems to be a large gap between poles and this suits the decogged magnets. To check, sprinkle some iron filings onto a magnet inlay. The iron filings will be attracted to the boundries between North and South. If they are angled or arrowhead ..... well too bad, if square to the edge then decogging well worthwile. was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| retepsnikrep Senior Member Joined: 31/12/2007 Location: United KingdomPosts: 131 |

From the bits of swarf  etc that collected whilst I was messing about with this I could see the magnets appeared to be rectangular. etc that collected whilst I was messing about with this I could see the magnets appeared to be rectangular. Gen1 Honda Insights. |

||||

| retepsnikrep Senior Member Joined: 31/12/2007 Location: United KingdomPosts: 131 |

Up and running. Generating fairly easy 12v at 1 amp in low turbulent wind.  Now charging a 12v battery. Now charging a 12v battery.

Poor pic as light very bad today.

My weather station mounted on top. Whole set up is about 12ft off ground on a flat car port type roof between two buildings. Sadly I just don't have anywhere else to mount it :( Youtube video showing it going round in light wind. Gen1 Honda Insights. |

||||

| solarwind Regular Member Joined: 03/02/2008 Location: South AfricaPosts: 51 |

Impressive! Can't wait to hear more, also with more wind.Congrats! You don't have success until you've tried it! |

||||

| retepsnikrep Senior Member Joined: 31/12/2007 Location: United KingdomPosts: 131 |

My VAWT unit makes virtually no noise, and is much quieter than my HAWT Air-X 400W on the adjacent mast. It also starts up in very little wind. Savonius in better light Savonius and Air-X Gen1 Honda Insights. |

||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 224 |

Hello Peter,Im impressed with your efforts.Thanks for taking the time to show us what you have done.I am also in the process of producing a Savonius and I will be looking forward to your results for comparison.I also visited your webpage and was stoked with what you have achieved.Electric vehicles ect.Well done and inspired. Anthony. "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 224 |

Hello again.One more comment regarding noise from cogging.I had the same issue with the drums amplifing the cogging sound and was ready to give the project away.But as I suggest in another part of this site i took up another members idea of twisting the poles and the noise has virtually dissapeared.I have posted some Photos and dimensions for same.Although yours will be a little different.If I'm over visiting my wifes family in Belgium Ill call in for a look. Anthony. "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 224 |

Hello again,what criteria did you use to detirmine your overlap of drums about the axle and the apperture between the axle and inside edge of drums.ie was there a formula for transfer of air volume from one drum cup to the other and did this detirmine the apperture. Anthony. "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5019 |

Good work Peter. I like the YouTube video, its good to see the vertical windmill working for you. Anthony I had a noise problem with my Lenz2 vertical windmill. Sounded like a motor bike in the back yard! I rounded my stator poles and also had a big reduction in noise. It was suggested at the time I try a rubber coupling, never did try it but I think it would work. I think the old Fiat cars used a rubber coupling as a universal joint, could be worth giving one of those a go. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 224 |

Hello again Peter and Glenn thanks for your suggestion.Peter could you tell what is the height is of the drums you have used.I am trying to accertain if they are a standardised height globally and what radius/diam the projecting rolled edge is on the top and bottom of drum from manufacture.ie where top and side of drum are joined.In my makeshift wind tunnel and pursuant to other literature on wind turbulance I feel a small modification to your mill may help.By attaching (weld) a strip of metal approx 30mm wide x 2mm thick along the trailing edge of each drum cup from the rolled edge top to bottom rolled edge and picking up the two rolled ridges with a rivet.One it makes the edge stiffer and two it in my tests reduces the turbulance off the trailing edge.As the air passes through the gap created along the trailing edge a more laminer flow is created.Hence improving effiecency.If you consider this a reasonable conclusion and try it out I am most interested in the data before versus after.Sorry to pester you with so many posts but this site is just ace for like minded windheads to communicate. Again well done. Anthony. "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

| retepsnikrep Senior Member Joined: 31/12/2007 Location: United KingdomPosts: 131 |

I used standard 45 gallon drums, sorry I don't know the height off the top of my head. The apperture in my case is about 1/4 width of drums. A bit small really. I'm moving onto MK2, now so won't be tinkering much with this one. Gen1 Honda Insights. |

||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 224 |

I am just looking at making a generic frame work axle to support Savonius drums that I may try to market one day so the variation in height interest me.When you get a chance a dimension would be apprieciated.But no hurry. Anthony. "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

Tinbender Newbie Joined: 03/02/2008 Location: United StatesPosts: 14 |

Peter! Peter! ...Look What I Got! <------- It landed in my yard after that last hard wind. VAWTs Up Doc? VAWTs Happening? Is that VAWT you vant? VAWT vere you thinking? |

||||

| Page 1 of 2 |

|||||